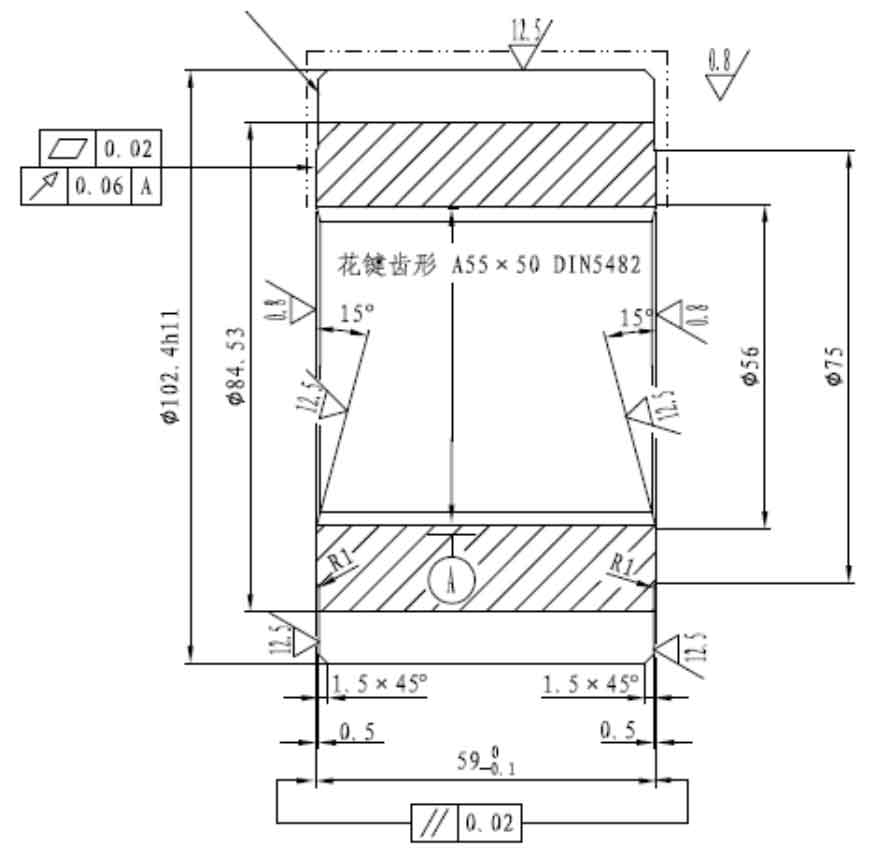

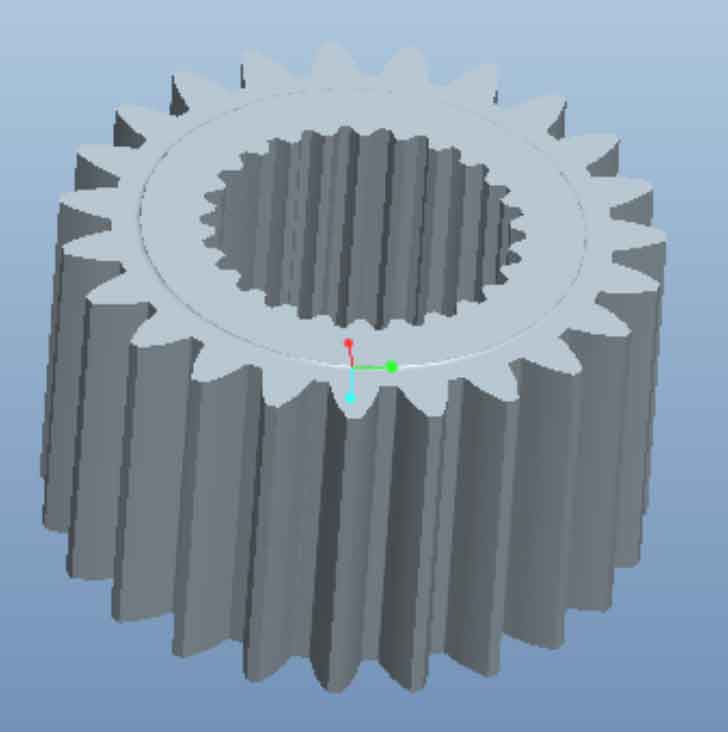

Taking the sun gear in a truck wheel reducer as the research object, its part drawing and three-dimensional solid model are shown in Fig. 1 and Fig. 2, including spur gear parameters and involute spline parameters.

The external teeth of the sun gear part are positive displacement large module spur cylindrical gears, the diameter of the tooth top circle is up to 102.4mm, the height of the spur cylindrical gear is close to 60mm, and the internal teeth are positive displacement involute spline teeth, with a large number of teeth and slender. The structural characteristics of parts determine the great difficulty of forming. At present, many domestic universities and research institutes have carried out the research on the forming and process of spur gears, which are still in the stage of theoretical analysis and laboratory trial production. At present, the main technical difficulties are that the large forming load accelerates the wear and cracking of the die, difficult demoulding, easy roughening and low service life of the die; During the forming of parts, the tooth top has collapse angle, the filling is not full, and most of them adopt non through forming, the blank can not fully form the tooth shape, the upper end face often needs to reserve a large amount of cutting allowance, and the material utilization rate is low; The accuracy of spur gear of formed parts can not meet the requirements of direct loading. Generally, the tooth surface needs to be processed later to meet the requirements of assembly and use. For example, adding gear grinding process to improve the accuracy of spur gear greatly reduces the production efficiency.

Generally, the average service life of warm and hot forging dies is only a few thousand pieces per set, but the service life of cold forging dies is generally tens of thousands of pieces per set, or even hundreds of thousands of pieces per set. The manufacturing cost of spur gear die is high, and the service life of die has a great impact on the comprehensive economic cost of parts production. The comprehensive economic cost directly determines whether the forming process can be popularized and applied to industrial mass production.

Therefore, based on the research of cold extrusion forming process, it is planned to design a variety of forming process schemes for exploration and analysis, select the best forming process scheme, carry out die optimization design, processing and manufacturing, and carry out production trial production in the factory.