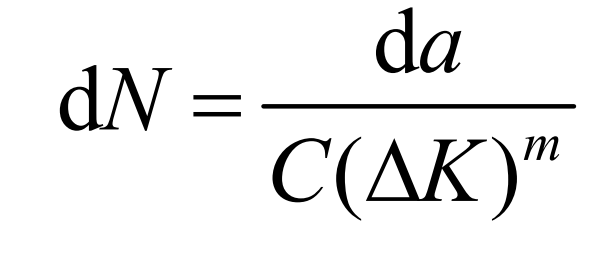

Within the range of elastic mechanics, Paris gives the fatigue crack growth rate of spur gear expressed by the formula, and deforms the formula to obtain:

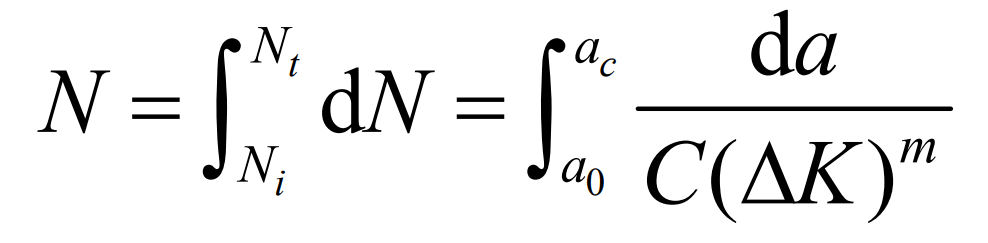

By integrating both sides of the formula at the same time, the formula for calculating the fatigue crack propagation life of spur gear can be obtained:

Where, A0 is the size before crack propagation of spur gear, and AC is the critical size of fracture failure; Generally, the former is determined by the initial crack size, and the latter is given a relatively reasonable value by the analyst according to the actual component size.

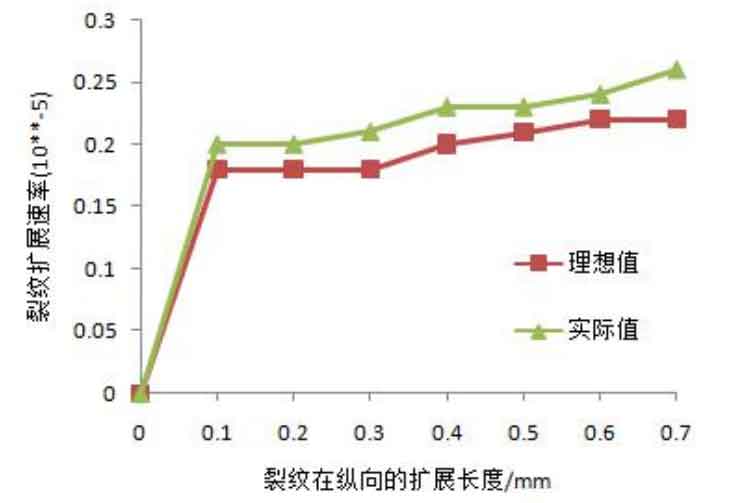

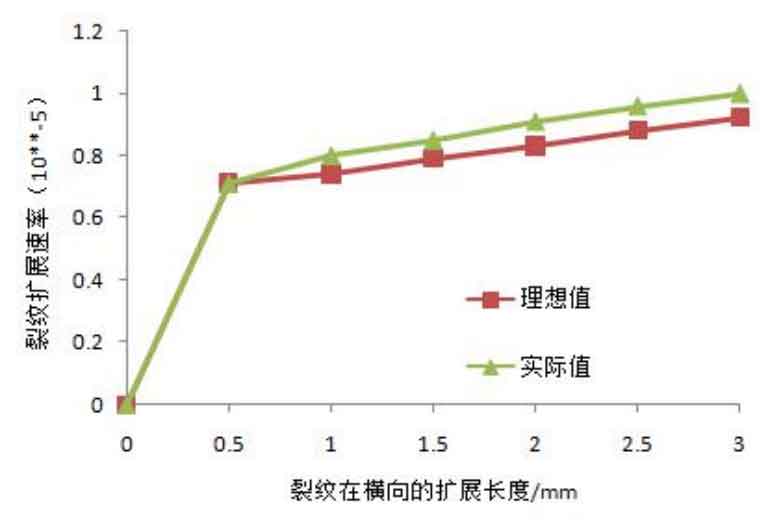

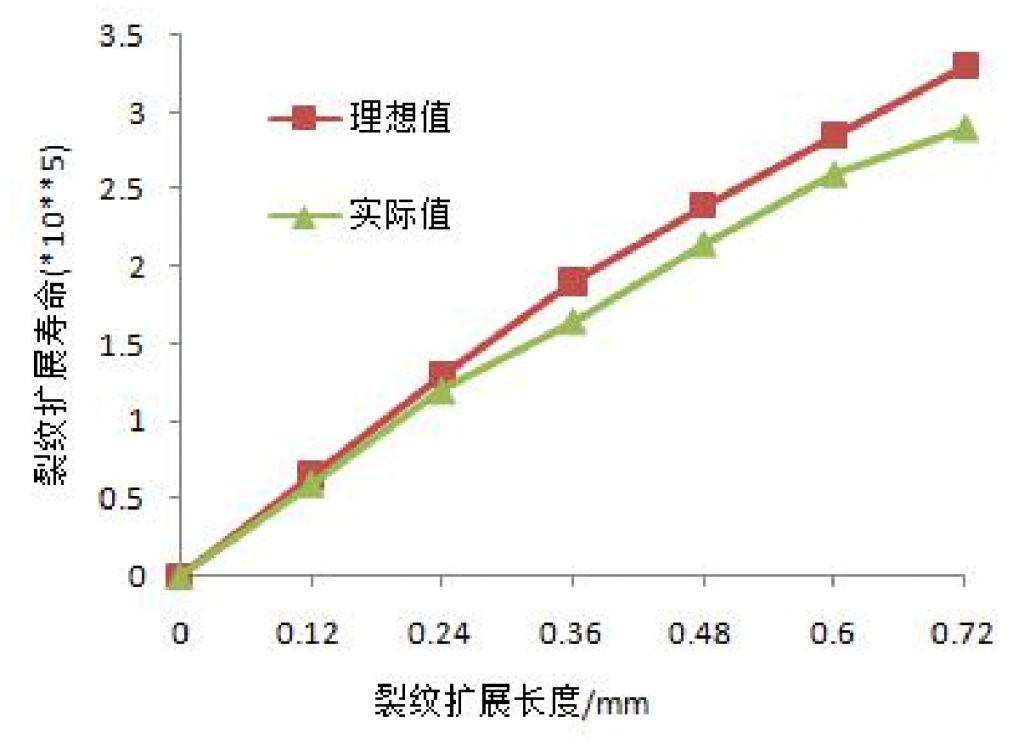

When using FRANC3D to predict the fatigue crack propagation life of spur gears, the formula α I 、 α The values of II are taken as 1.155 and 1 respectively, and then the relevant material parameters are input. The temperature is set at room temperature. Finally, the crack propagation life of spur gear under two different tooth direction distributed loads is predicted respectively, and the data are sorted to obtain the crack propagation life curve of spur gear shown in Figure 1.

In order to compare the crack growth life of spur gear under ideal uniform load and actual load, the crack life when the path length is 0.7mm is taken from Figure 2: the crack growth life under ideal uniform load is about 3.2 × 105, the crack propagation life under actual load is about 2.9 × 105。 It can be seen from the above results that the uneven distribution of load between points on the contact line will shorten the crack propagation life. If the crack propagation life is measured by the surface crack length of spur gear root, the surface crack length can be taken as 5mm, and the crack propagation life under ideal uniform load is 325000 and 320000 respectively under actual load. The results show that the two methods to measure the crack propagation life are equivalent, but they represent the crack propagation life of spur gears from different angles.

From the results of predicting the crack propagation life of spur gears, the crack propagation rate and crack propagation life of spur gears are very different under two different loads. In connection with the actual meshing situation of spur gears, the uneven tooth direction distribution of load will reduce the fatigue propagation life of spur gears. This conclusion is consistent with the results of crack propagation rate analysis of spur gears. By connecting this conclusion with the tooth direction load distribution coefficient, it can be inferred that the greater the tooth direction load distribution coefficient is, The fatigue crack propagation life of spur gears is shorter.

From the above analysis results, we can see that the uneven load distribution in the tooth direction has a great influence on the crack propagation life of the tooth root of spur cylindrical gear; In practical application, the degree of uneven load distribution should be minimized, such as reducing the tooth width when meeting the engineering needs, or reducing the bending of the shaft by increasing the stiffness of the shaft connecting the spur gear. In addition, special treatment can be carried out at the dangerous position of the tooth root to increase its strength.