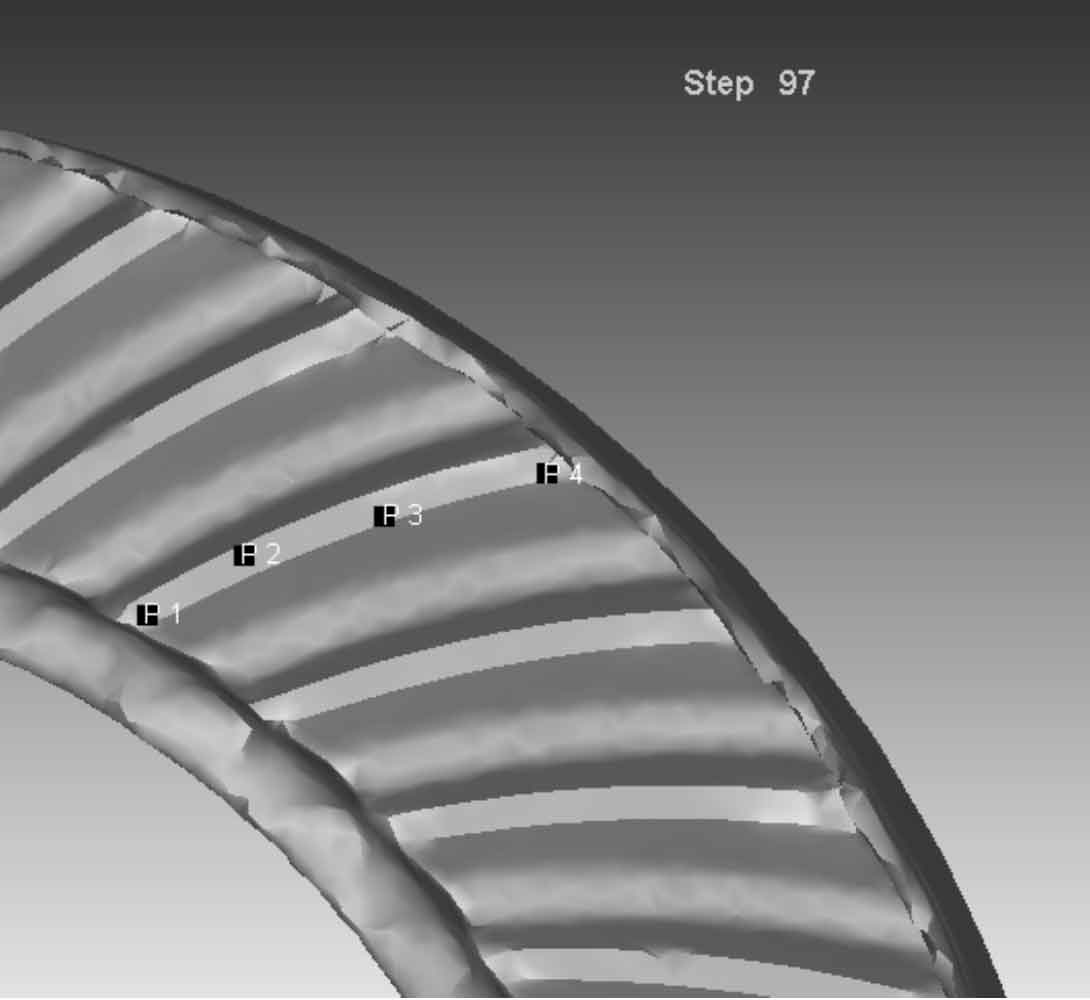

Four points are selected at the tooth top of spiral bevel gear forging, and the position distribution is shown in Figure 1.

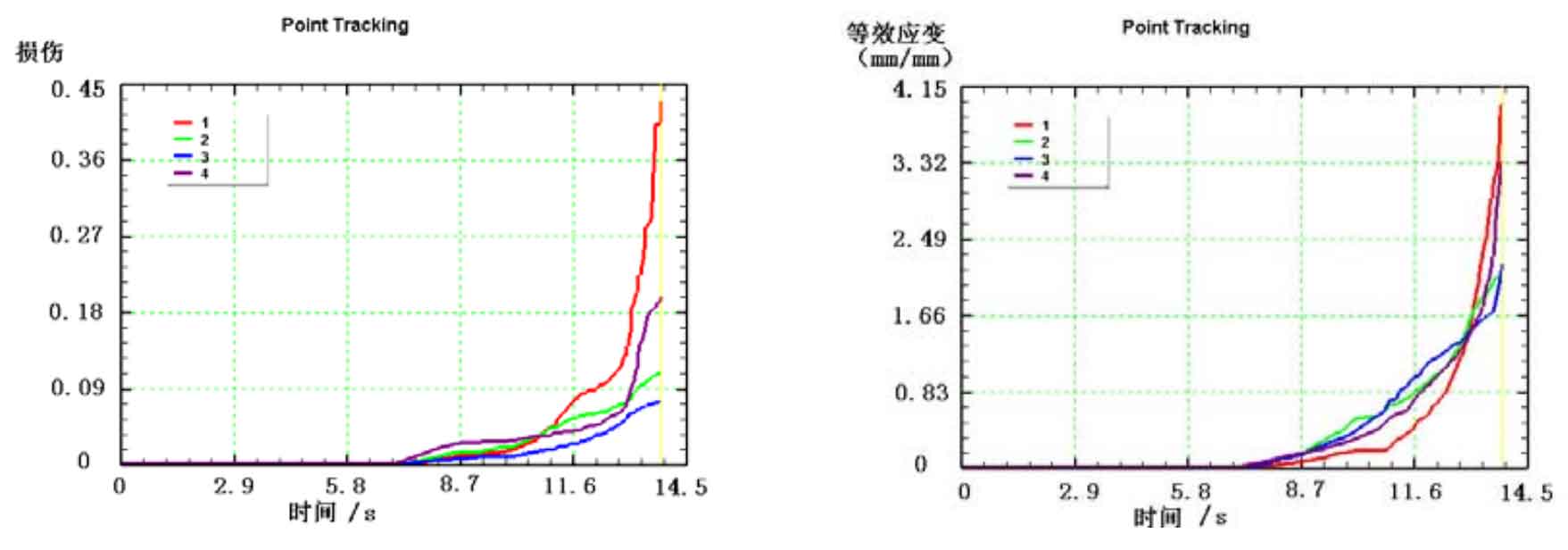

Select 4 position points on the tooth top and number P1 ~ P4 from small end to large end. The damage and other results are shown in Figure 2.

(b) 4-point equivalent strain diagram of tooth top – hot forging

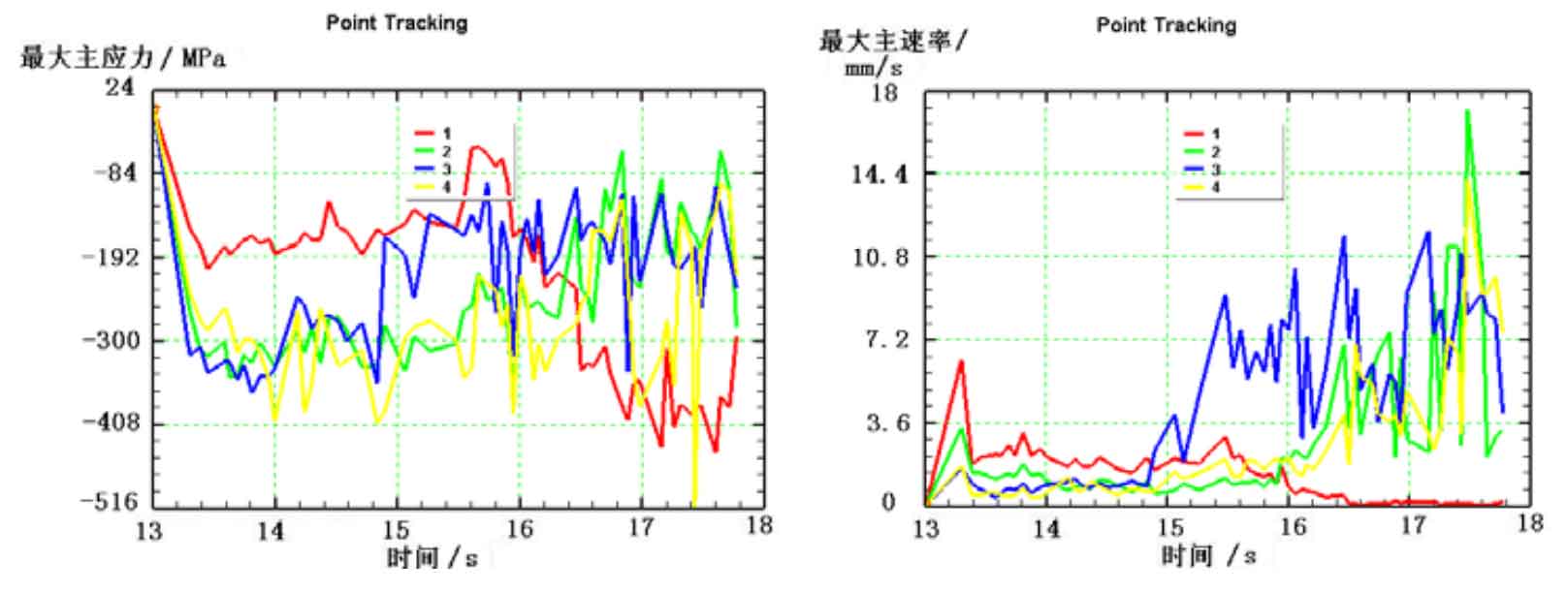

(d) Maximum principal velocity diagram of 4 points on tooth top – hot forging

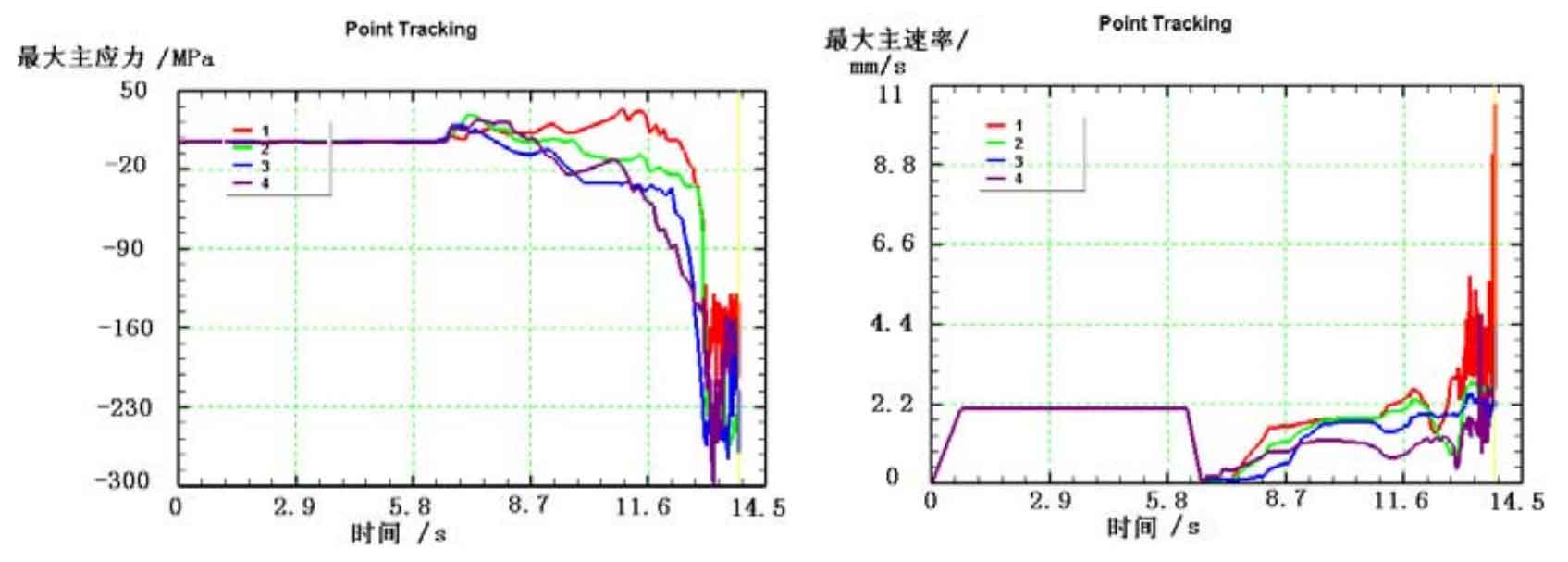

(f) 4-point equal effect variation diagram of tooth top – cold finishing

(h) Maximum principal speed diagram of 4 points on tooth top – cold finishing

It can be seen from Figure 2 that the damage, material flow, maximum principal stress and equivalent strain distribution of four different positions are determined. A ~ d is the condition under the condition of hot forging, e ~ F is the condition during the cold finishing process. Point P1 is located near the tooth top and inside the tooth. The damage, equivalent strain and The maximum principal stress and material flow equivalent are higher than other points on the tooth top, indicating that this position is where the material flow is large. In the cold finishing state, the equivalent effect change and maximum principal rate of this point are small, while the damage and maximum principal stress equivalent are still at the high point, and the process fluctuates greatly, which is caused by the unstable contact between the die and the blank in the finishing process, P4 point is located at the top of the gear and close to the outside of the gear. The damage of this point during hot forging is small. The equal effect variable value and the maximum principal stress value are located in the middle of the four points. The maximum principal rate begins to increase to a certain value, then remains unchanged, and then decreases to a certain value. Then the change is similar to the other three points. The damage of this point during cold finishing is second only to P1 point, The equivalent strain and the maximum principal velocity are located in the middle of the four point values. The maximum principal stress belongs to the minimum position of the four point values, and the numerical fluctuation is still large. P2 and P3 can be analyzed through the same process.