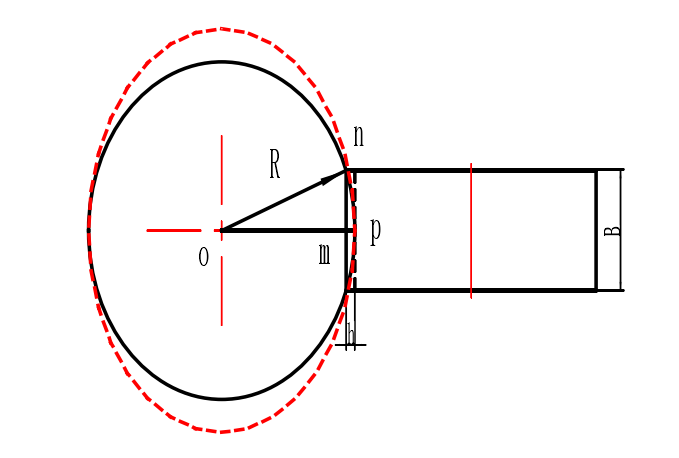

The tool radial runout error ∆ mainly affects the tooth profile error of the gear. The modeling is shown in the figure. The tooth profile error is:

Where, α The end is the pressure angle of gear hobbing hob.

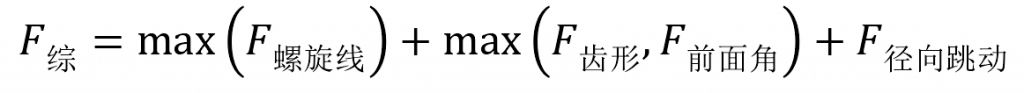

To sum up, we know that the errors of the tool are to describe the deviation of the actual cutting edge from the helical surface and the shaping error of the cutting edge. The helix error describes the deviation of the actual cutting edge from the helical surface, and the gear profile error and rake angle error describe the modeling error of the cutting edge. The influence of the tool with error on the gear hobbing accuracy is the intersection of the tolerance zones processed by each single error. Therefore, we can get the comprehensive influence of the tool error on the gear hobbing error: