The machining error of gear is determined by the process error factors of machine tool, cutting tool, wheel blank and fixture in the process system. Taking the gear hobbing process as an example, the main error sources can be classified. There are many sources of machining errors affecting the gear hobbing process. The hob made of involute basic worm avoids the hob profile error in principle.

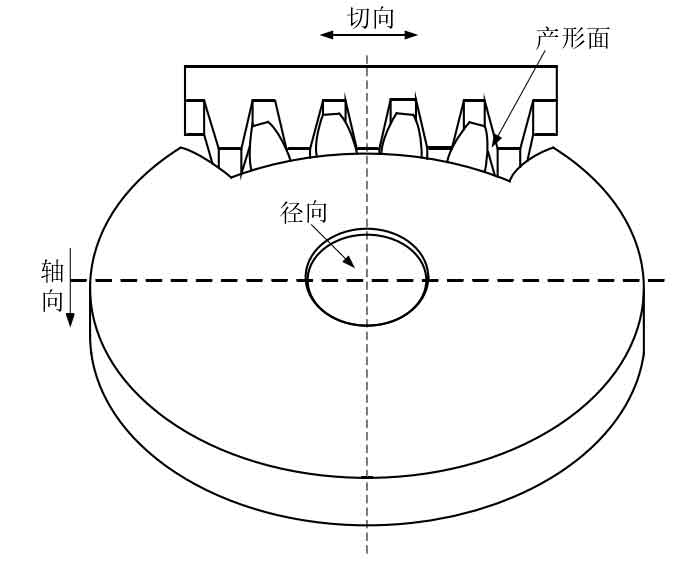

As shown in Figure 1, the gear hobbing error of cylindrical gear can be summarized into the following four types according to the gear rotation direction when the error occurs:

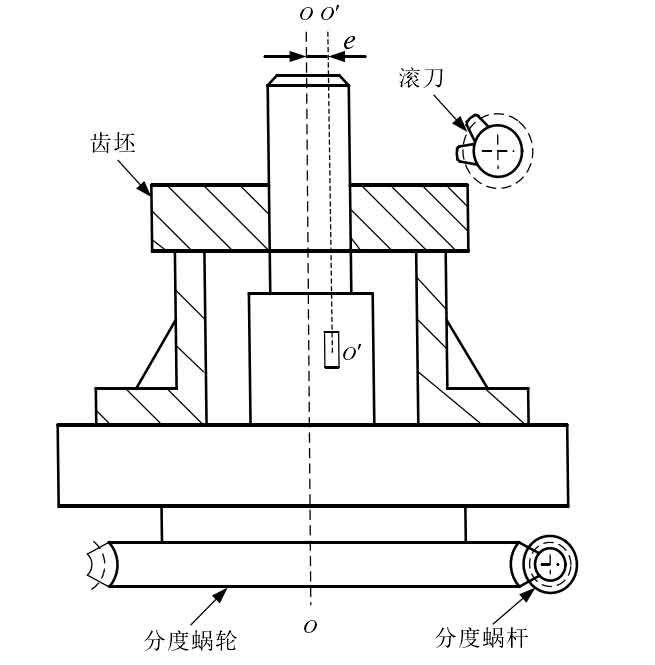

The tangential machining error is mainly caused by the destruction of the generating motion between the gear hob and the gear blank according to the fixed transmission ratio. The error of gear hobbing machine with indexing mechanism is caused by indexing error. The error caused by indexing worm gear makes the processed gear eccentric, as shown in Figure 2. The root cause of tangential machining error is the error of feed screw in the extended motion chain of gear hobbing machine tool.

The axial machining error is the error caused by the deviation of the gear hob moving along the axis of the machined gear.

1) Error of hob holder guide rail of gear hobbing machine tool. The tool holder guide rail is that while the hob moves along the axial direction of the workpiece, it produces skew under the action of cutting force, resulting in inconsistent depth of the processed gear profile.

2) End face runout of gear blank. During gear hobbing, because the datum positioning of gear blank is not accurate enough, the end face of gear blank will run out, which will cause the position of gear axis to tilt relative to the theoretical axis.