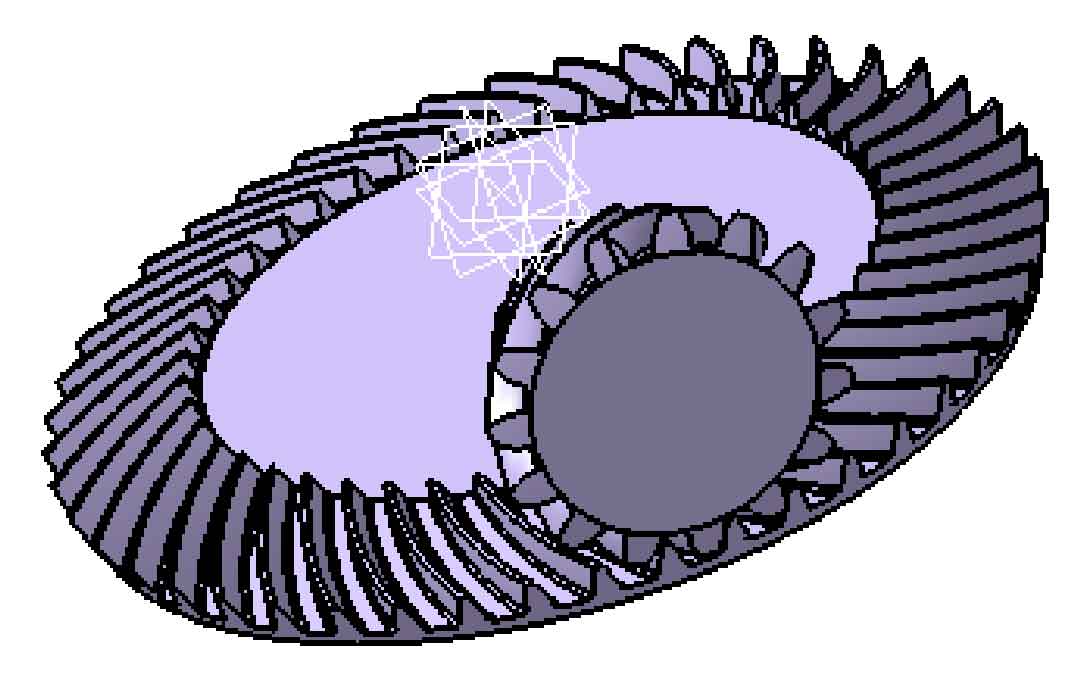

For assembly in CATIA, firstly, the driving and driven spiral bevel gears are respectively introduced into the rotating body, then the position of the big gear is fixed, and then the axes of the two gears are perpendicular through angle constraint, and then the base cone vertices of the two gears are overlapped through point distance constraint, so as to activate the collision, make the pinion rotate around its axis to collide with the big gear, and finally update the whole assembly, The figure is the assembly drawing of spiral bevel gear model.

After assembly, interference inspection shall be carried out for spiral bevel gear pair. The actual movement of spiral bevel gear should be the contact between the tooth surface and the tooth surface, that is, the two working tooth surfaces should be tangent, and there should be no interference between geometric bodies. If the established model has interference, it will affect the simulation analysis and make the analysis results inaccurate. The interference inspection analysis in CATIA is the interference inspection result of two spiral bevel gears, which shows that there is no interference in the assembly process.