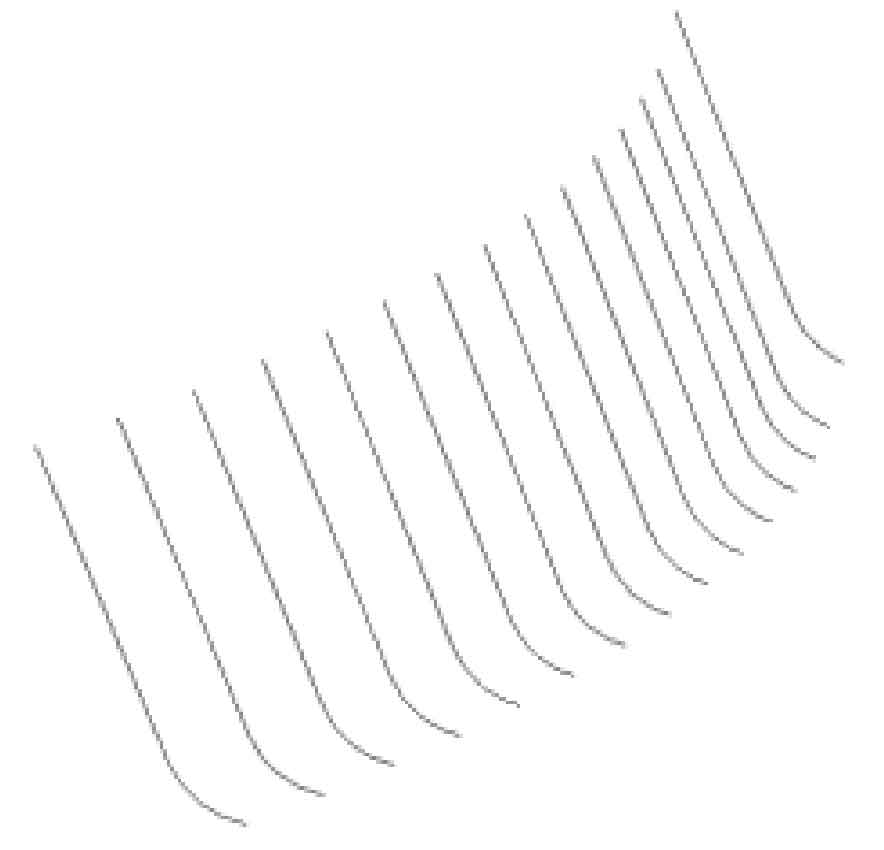

According to the point cloud construction curve of arc tooth surface gear, firstly slice the point cloud several times along the tooth length direction to obtain several point cloud slice lines, as shown in Figure 1. It can be seen from Figure 1 that the curved surface of the arc tooth surface gear is composed of two parts: the working tooth surface of the arc tooth surface gear and the transition surface of the tooth root. Therefore, the tooth surface should be constructed according to two parts.

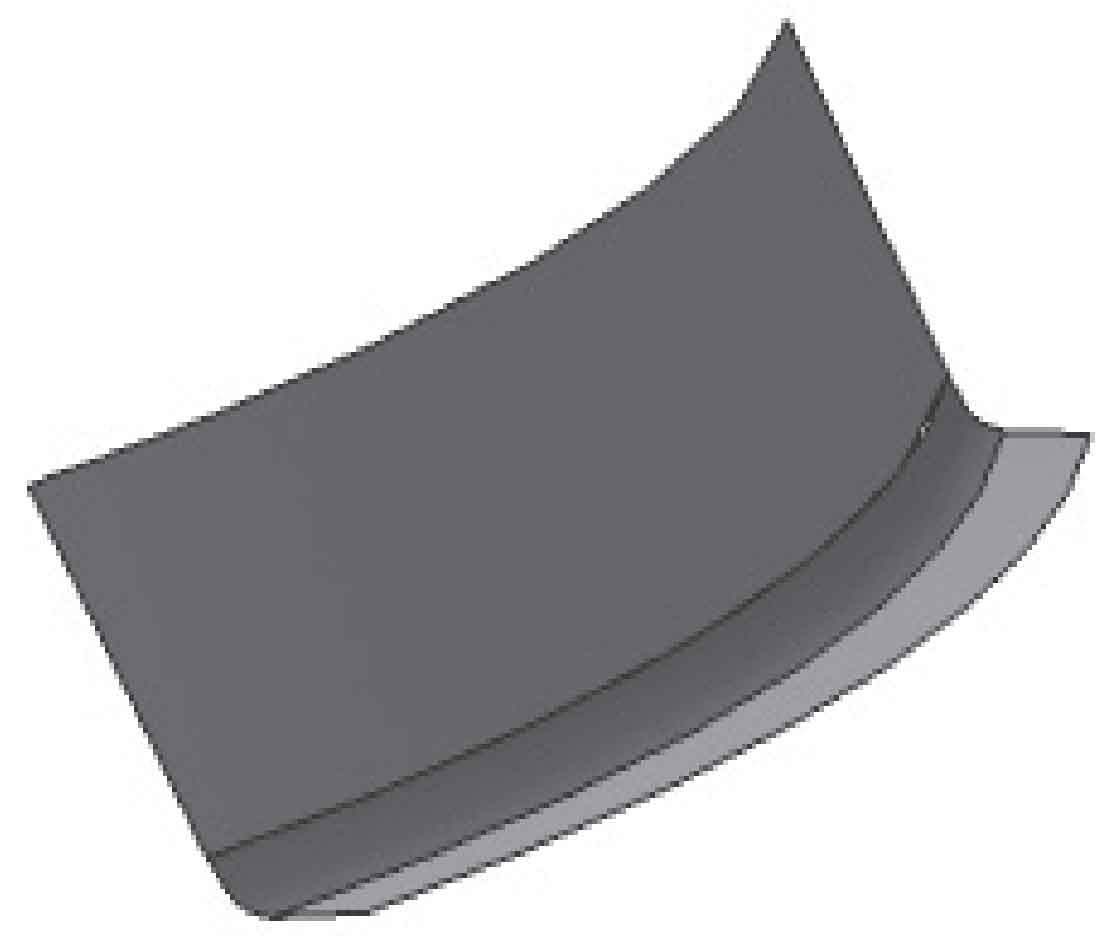

The tooth bottom surface of arc gear is a plane, which can be obtained by cutting. It can be seen from Figure 1 that the curvature of the point cloud slice line of the arc tooth surface gear changes greatly on the tooth root transition tooth surface, and more control points are required by the conventional curve construction method. Different from the working tooth surface of arc tooth surface gear, the tooth root transition surface is a non meshing surface and has low requirements for surface quality. Therefore, the modeling method of bridging surface is used to construct the surface, that is, bridging surface is used to connect the working tooth surface and tooth bottom surface. The bridging surface shall be tangent continuous with two adjacent surfaces. When constructing the bridge surface, adjust the tension of the surface to make it consistent with the point cloud of the arc tooth surface gear as much as possible. The error between the constructed tooth root transition surface and the point cloud is less than 0.02 mm, as shown in Figure 2.