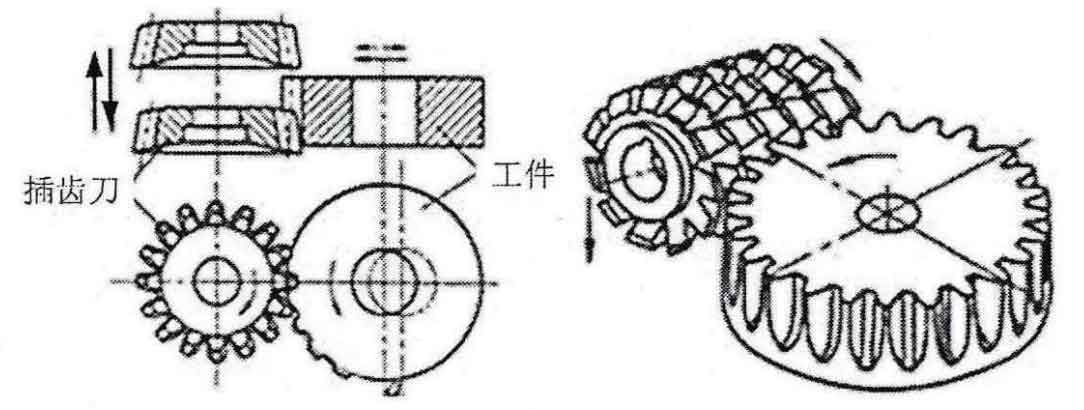

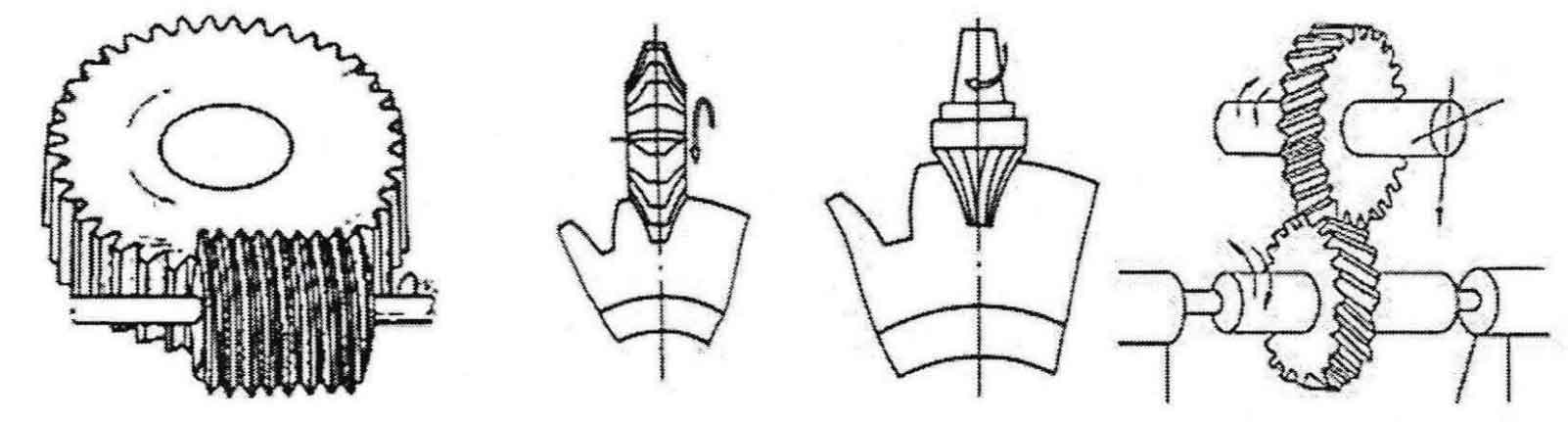

The key of involute gear machining is tooth profile machining. According to whether the material needs to be removed, the methods of involute gear machining can be divided into cutting machining and plastic forming. At present, the method of Machining Involute Gears in industrial production is still mainly cutting. The machining of involute gear can be divided into forming method and generating method according to the formation mode of tooth profile, as shown in Figure 1. Forming method is a method of forming gears with tools corresponding to the tooth shape to be machined, such as common milling gears. The advantage of milling is that it can be processed on an ordinary milling machine without adding new equipment. However, when milling, each tooth must be indexed after milling, so the production efficiency is not high and high precision cannot be achieved. When Machining Involute Gears with the generation method, no matter whether the number of teeth is the same or not, as long as the modulus and pressure angle of the gears to be machined are consistent with the cutting tools, they can be processed with the same set of cutting tools, which brings great convenience to the production of involute gears. Therefore, the generation method has been more widely used. The common generation machining processes include gear hobbing, gear shaping, gear shaving, gear honing, gear grinding, etc. they all process involute gears according to the principle of gear backlash free meshing.

Compared with traditional cutting, the production of involute gear and gear like parts by plastic forming has many advantages, such as high material utilization, high production efficiency, uniform and dense arrangement of metal fibers on the tooth surface along the tooth profile, which makes the gear have high mechanical properties. Therefore, it is generally believed that the future development trend of involute gear processing is to use plastic forming process to produce involute gear hairy or directly produce gear parts and gradually replace the existing cutting process. The plastic forming processing method of involute gear began in the 1950s. This process method does not require or only a little follow-up processing, and can obtain a certain precision gear only through forging. This involute gear manufacturing technology is often called involute gear precision forging.