The transmission error of straight bevel gear is one of the main internal incentives to study the dynamic performance of gear transmission system. The transmission error can be considered as the distance between the actual position of driving and driven straight bevel gears from the ideal position when straight bevel gears mesh. The ideal position is the position of teeth when large and small straight bevel gears are rigid bodies and the tooth profile shape is involute in the ideal state.

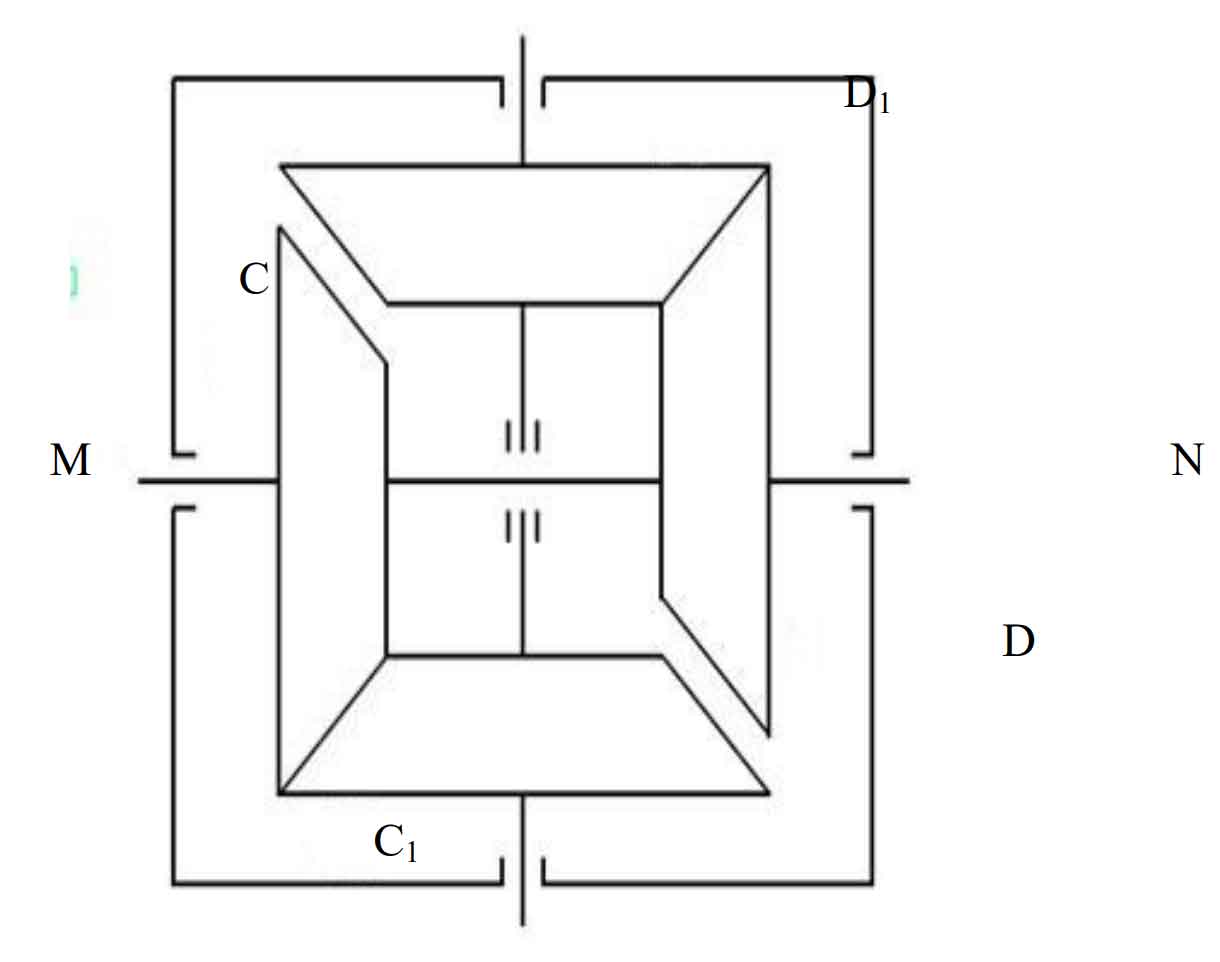

As shown in the figure, C and C1 are ideal straight bevel gears, D and D1 are actual straight bevel gears, the basic parameters of C and D (including number of teeth, modulus, etc.) are exactly the same, and the basic parameters of C1 and D1 are exactly the same. C. D two straight bevel gears are fixed on the same shaft with the same phase angle. C. D drives C1 and D1 respectively, and applies the rotation moment on the shaft Mn to make the straight bevel gears C and D rotate at the same speed. Due to certain errors between the actual straight bevel gears D and D1 and the ideal straight bevel gear, the rotation angles of D1 and C1 will be different at the same time. When straight bevel gears C and D rotate at the same time θ At 1 o’clock, D1 turns θ 2 ‘, C1 θ 2. The transmission error of straight bevel gear to D and D1 is as follows:

If the transmission error is described by the offset distance in the direction of the meshing action line of straight bevel gear, the transmission error can be expressed as follows:

Where: R is the indexing circle radius of straight bevel gear, 2 θ Is the actual rotation angle of straight bevel gear, 1 θ It is the ideal rotation angle of straight bevel gear.

The main causes of transmission error are tooth size error, deformation and dynamic characteristics. Manufacturing and installation error is one of the main sources of transmission error. They produce manufacturing transmission error and installation transmission error respectively. These two kinds of transmission errors are the results measured on the single tooth surface when the straight bevel gear works under no-load or light load and low speed.

In addition, the bending and contact elastic deformation in the process of tooth transmission form the time-varying meshing stiffness of straight bevel gear. The time-varying meshing stiffness will also cause the transmission error of straight bevel gear system. Therefore, the elastic deformation between teeth will have an impact on the transmission error of straight bevel gear. If it is under high load condition, it will have a greater impact on the transmission error of straight bevel gear.

Therefore, the change of transmission error directly reflects the vibration of straight tooth cone transmission system. The transmission error of modified straight bevel gear is analyzed by using romax designer software, and the dynamic response of straight bevel gear transmission is obtained by taking it as excitation.