According to the virtual machining theory, the geometric model of spiral bevel gear is created. The tooth system of spiral bevel gear is Gleason system, and the tooth height type is equal top clearance shrinkage tooth. Basic parameters of spiral bevel gear used.

There are many ways to machine spiral gears. The processing method used in this paper is single-sided method. That is, use double-sided cutters to cut the concave and convex tooth surfaces of the large wheel at the same time, and use two sets of single-sided cutters to cut the concave and convex tooth surfaces of the small wheel respectively. According to the basic parameters of the gear and the calculation formula, the parameters of the gear milling cutter head and the adjustment parameters of the corresponding machine tool are calculated. Among them, the cutter head parameters include nominal diameter, cutter tip distance, inner and outer cutter tip diameter, cutter tip width, cutter tip fillet radius, etc; The adjustment parameters of the machine tool include tool position, shaking table angle, eccentric angle, horizontal wheel position, vertical wheel position, bed position, installation angle and roll ratio.

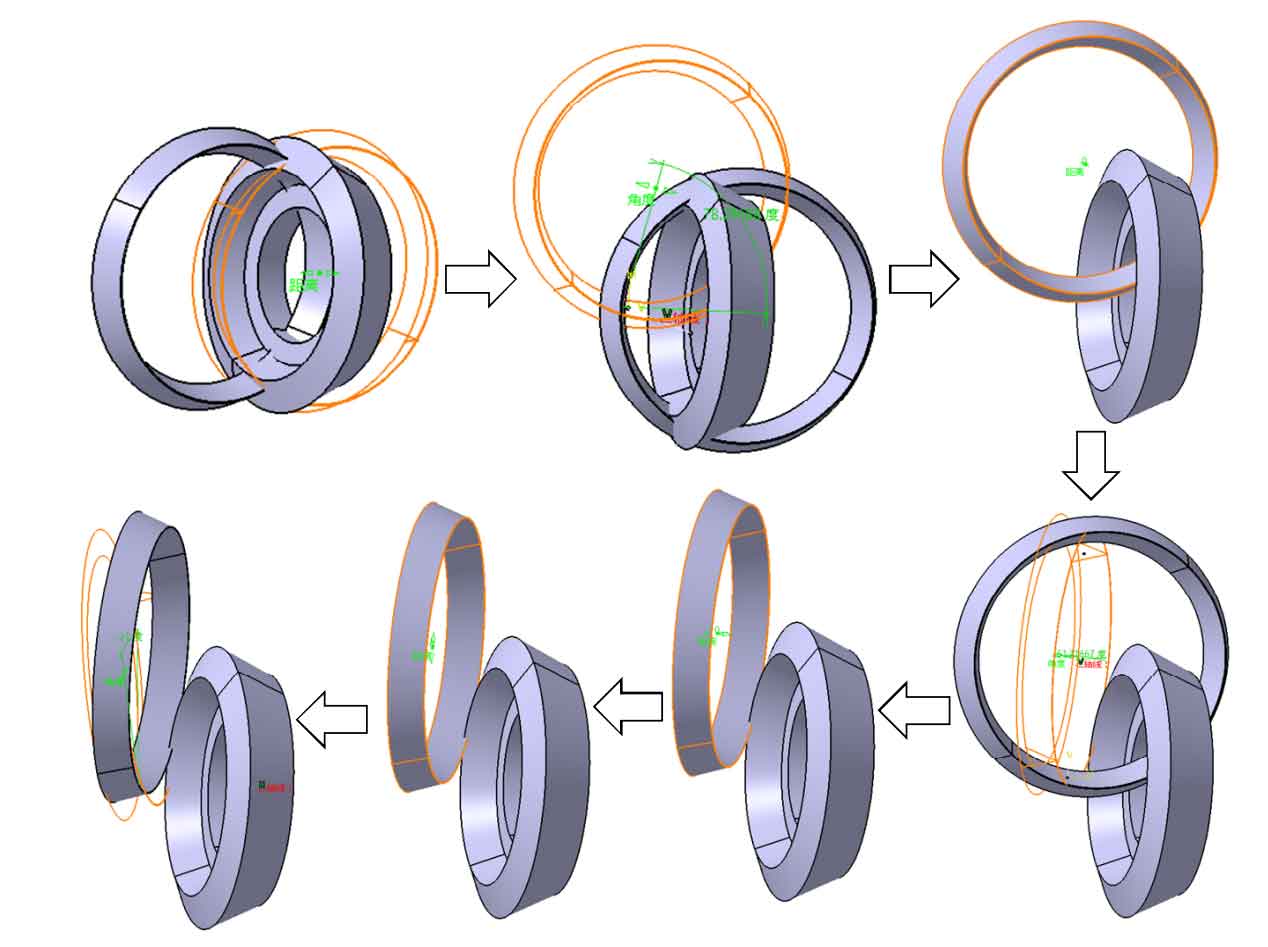

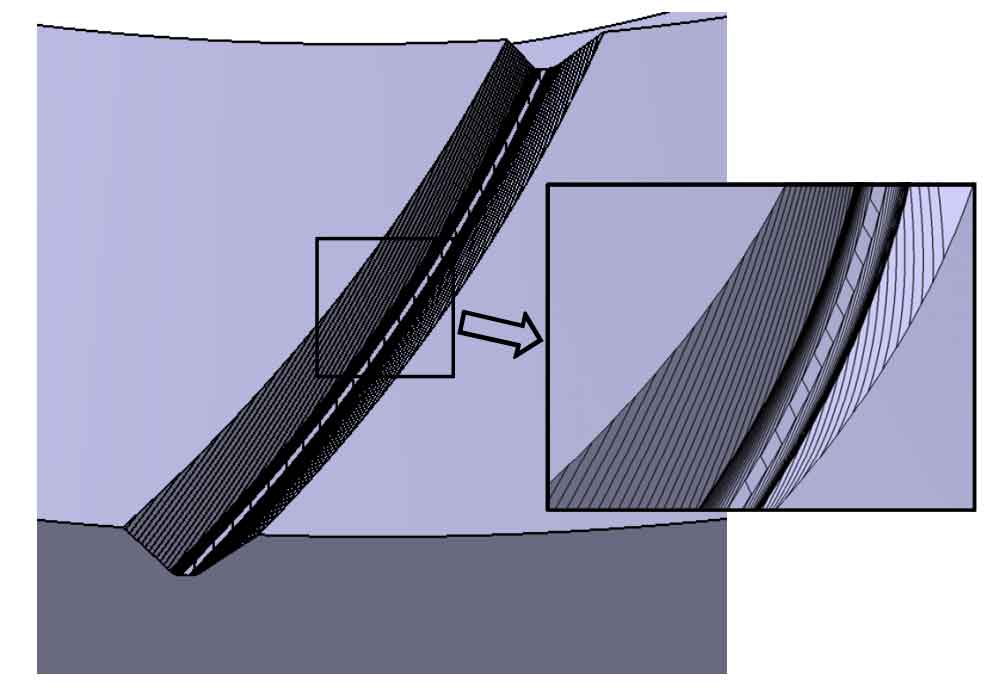

According to the virtual machining theory and machine tool adjustment parameters, the real machining process of spiral bevel gear is simulated by using the secondary development function in CATIA software. Adjust the parameters that determine the center position of the cutter head, the blank position and the motion relationship between the cutter head and the gear to be cut in turn. Figure 1 shows the position adjustment of large spiral bevel gear. After adjustment, the spiral bevel gear blank can be cut into a tooth groove envelope model. Fig. 2 is the envelope diagram of large spiral bevel gear. The cutting model obtained by this method can reflect the real machining process, and can obtain the tooth profile surface and tooth root surface of spiral bevel gear at the same time.