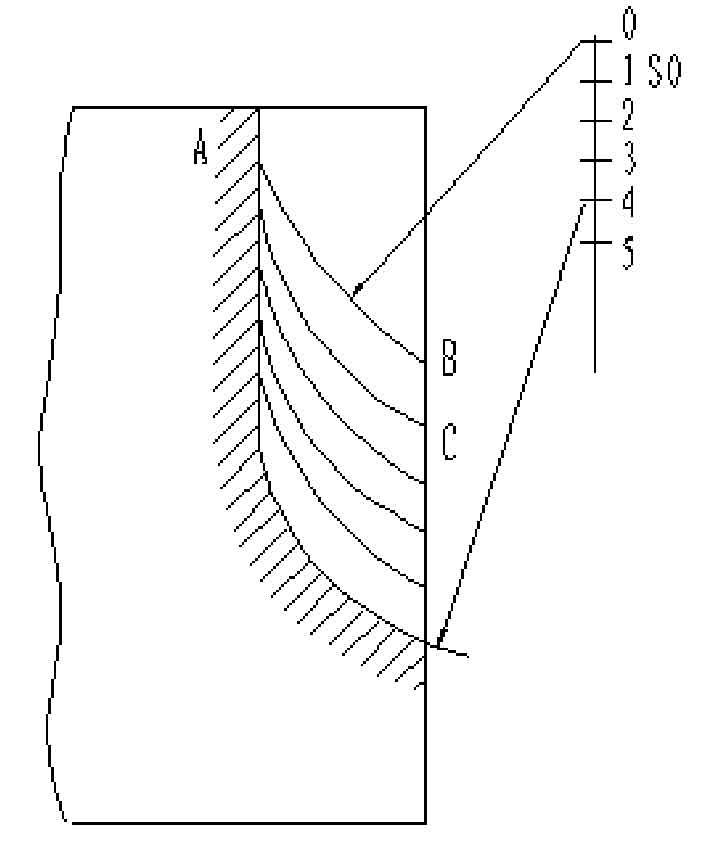

The forming method of gear hobbing tooth profile is shown in the figure. Starting from the contact cutting between gear hobbing hob and workpiece, the number of cutter teeth involved in cutting gradually increases, and will not increase after reaching a certain degree. When the cutting is about to end, the cutter teeth participating in the cutting are gradually reduced until the end of the machining.

In order to objectively reflect the cutting conditions of all cutter teeth participating in cutting in the cutting area, it is assumed that the gear has formed a complete tooth profile on the end face to analyze the cutting state when the gear hobbing hob continues to feed axially. According to this assumption, the initial position of the gear hobbing hob is at position 0, the workpiece rotates once, and the gear hobbing hob feeds along the axis of the workpiece. At this time, the ABC part of the metal is cut in the tooth groove, and the gear end face forms a complete tooth profile. The workpiece rotates again, the center of the gear hobbing hob is to position 2, and the metal with the same section as ABC is cut off in the tooth groove. In this way, the gear hobbing hob gradually cuts off all the metal in the tooth groove in the downward feed.