The forming process of open die forging of spiral bevel gear is blanking → less and no oxidation heating → blank making → rough forging → punching skin and trimming → surface cleaning → reheating → precision forging → cold trimming → surface cleaning → boring, back cone and rear end face → heat treatment → grinding inner hole. In this process, the blank needs punching skin, trimming and surface cleaning after rough forging, The temperature of the forging decreases greatly, so the blank needs to be reheated before precision forging, which increases the production cost and the oxidative decarburization of the forging caused by heating. In addition, the material utilization and production efficiency of open die forging of spiral bevel gear are low, the service life of die forging is short, and the subsequent processing is complex. The above problems are mainly caused by the following two points:

1) Due to the existence of flash and skin, not only a lot of metal is wasted, but also flash and skin are difficult to remove.

2) The forging deformation force required for the forming of spiral bevel gear forging is very large, and the working temperature of the die is high. The die will have problems such as plastic deformation failure and fracture failure of the tooth, which will affect the service life of the die forging .

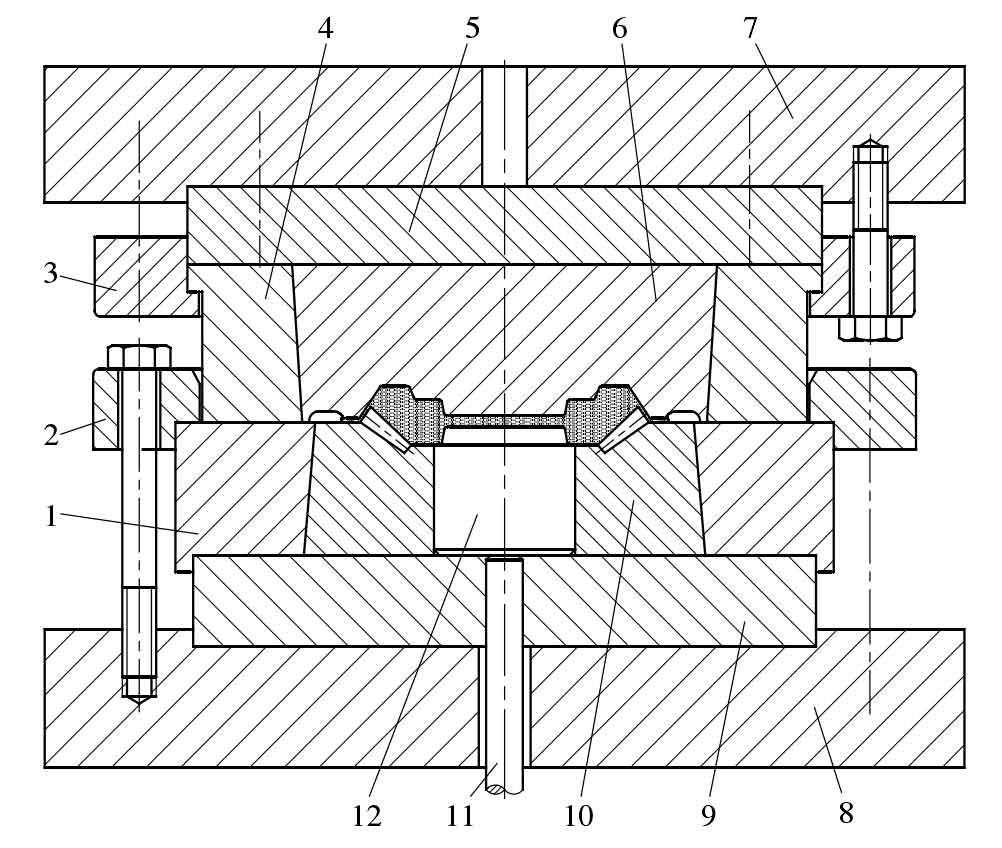

As shown in the figure, the precision forging die structure used for open die forging of spiral bevel gear is shown. The die adopts latch guidance, and the tooth shaped female die is installed on the lower die. The die structure used in rough forging is the same as that of precision forging, but there are some differences in cogging accuracy and die cavity size.

The working process of the spiral bevel gear die is as follows: put the heated blank into the gear die 10; When the slider of the press goes down, under the guidance of the pressing ring 2, the back cone die 6 first contacts and compresses the blank. When the upper die goes down to contact with the gear die 10, the forming process ends, the blank metal is formed under the force of the die bore, and the excess metal flows into the flash groove to form a transverse flash; The slider of the press returns and drives the upper die upward. The forging is pushed out of the tooth die by the ejector rod 11 and ejector post 12, and the spiral bevel gear forging is taken out to complete a working cycle.