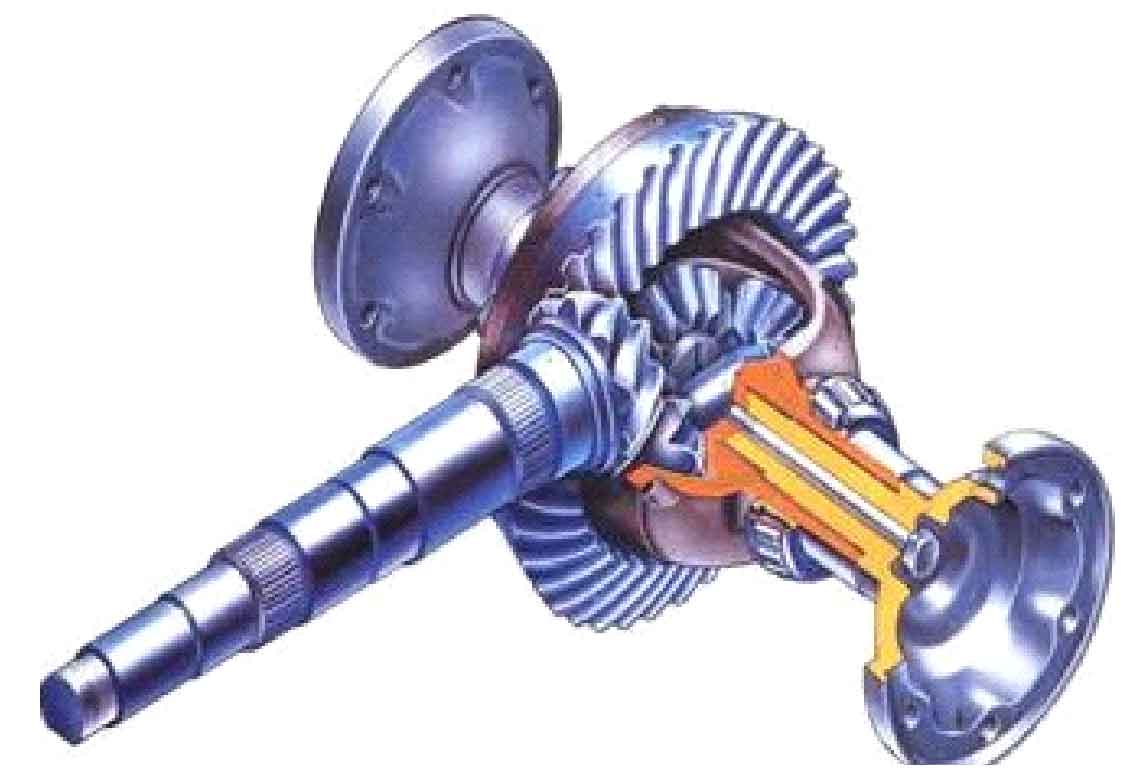

Automobile rear axle is also called drive axle. It not only bears the load, but also acts as differential and deceleration. The drive axle is located at the end of the automobile transmission. Its working principle is: the engine drives and generates torque through other transmission devices. The torque of the engine is transmitted to the wheels through the main reducer, differential and half shaft to drive the wheels. Through the above, the purpose of deceleration can be achieved; The transmission direction of torque is changed by using the spiral bevel gear pair on the main reducer; Finally, the differential is used to ensure that the wheels on both sides have differential speed, so as to realize the function of differential speed. At the same time, it can also realize that the wheels at different positions have different transmission directions and speeds. Figure 1 is the structural diagram of the drive axle.

Driven spiral bevel gear is an important component of automobile main reducer, with large bearing capacity and poor working environment. Therefore, it must have high quality accuracy and good mechanical properties to ensure the smooth and safe operation of the automobile, as shown in Figure 2. Because the driven spiral bevel gear of automobile rear axle plays such an important role, it also has high requirements for its forming forgings. In the design process, it is necessary to accurately calculate the geometric size and load of the gear blank, and improve all aspects of the performance of the gear as much as possible. There are also high requirements for the selection of materials, which should have better performance parameters such as yield strength and tensile strength.