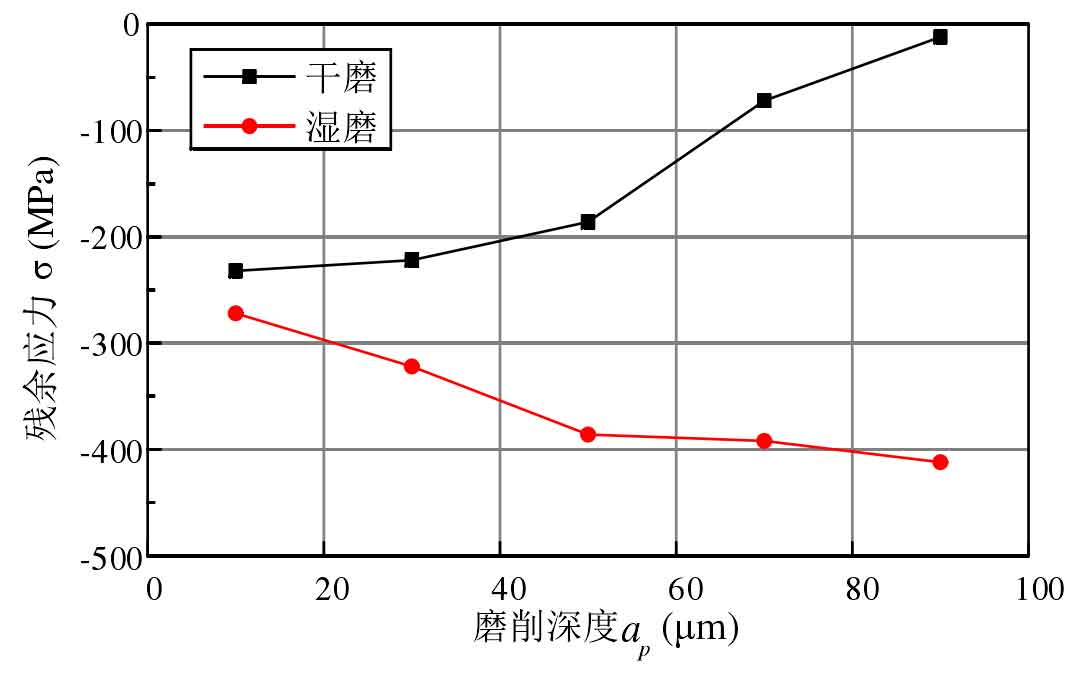

This paper studies the strengthening effect of cylindrical gear steel grinding on the surface properties of 30crmnti material. The main research is the variation law of workpiece surface properties under the condition of dry grinding. However, in actual production, the cooling mode of wet grinding is generally adopted, and the cooling mode has a great influence on the residual stress after cylindrical gear steel grinding. Therefore, the wet grinding test is carried out under different grinding depths AP with fixed grinding speed vs = 20.3 M / s and workpiece speed VW = 1200 m / min, Quantitatively study the variation law of residual stress under dry / wet grinding state, and the results are shown in the figure.

It can be seen from the figure that the change trend of residual stress under wet grinding is very different from that under dry grinding. Under the condition of wet grinding, with the gradual increase of grinding depth of cylindrical gear steel, the value of residual compressive stress increases gradually. This depends on the good cooling effect of the cylindrical gear steel grinding fluid used in the test. It can be observed that under the condition of wet grinding, there is almost no spark in the grinding process of cylindrical gear steel and the surface temperature can be reduced. At this time, the residual compressive stress caused by grinding force plays a major role, while the residual tensile stress caused by grinding heat of cylindrical gear steel has little effect. Therefore, under the condition of wet grinding, the grinding force of cylindrical gear steel increases significantly with the increase of grinding depth, resulting in the increase of residual compressive stress on the grinding surface of cylindrical gear steel.