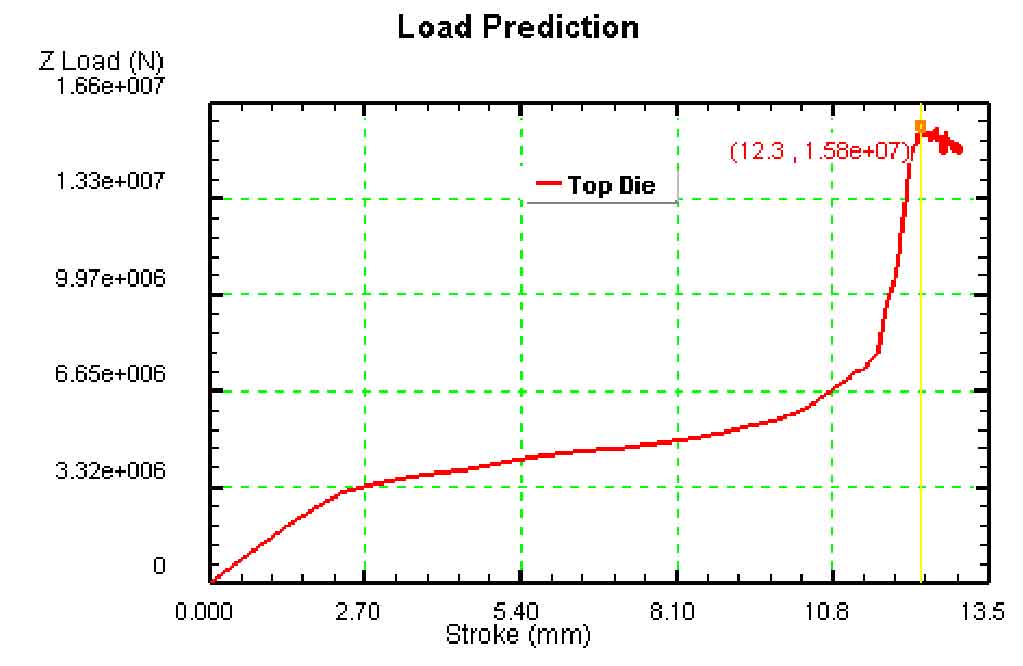

During the precision forging process of the driven spiral bevel gear of the automobile rear axle, the load will change with the change of the stroke of the upper die. Figure 1 shows the stroke load curve obtained by the numerical simulation of the precision forging process of the driven spiral bevel gear of the automobile rear axle. From the figure, it can be seen that the whole curve can be divided into four stages: when the stroke of the upper die is 0 ~ 2.7 mm, the load has a linear relationship with the stroke, and the load increases evenly with the increase of the stroke.

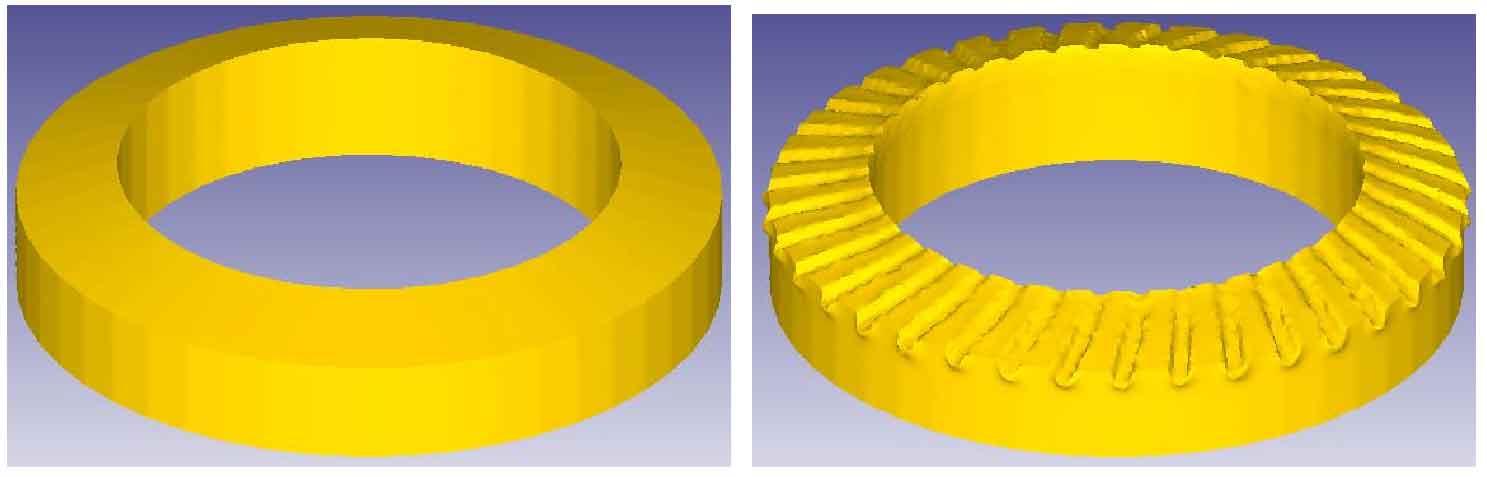

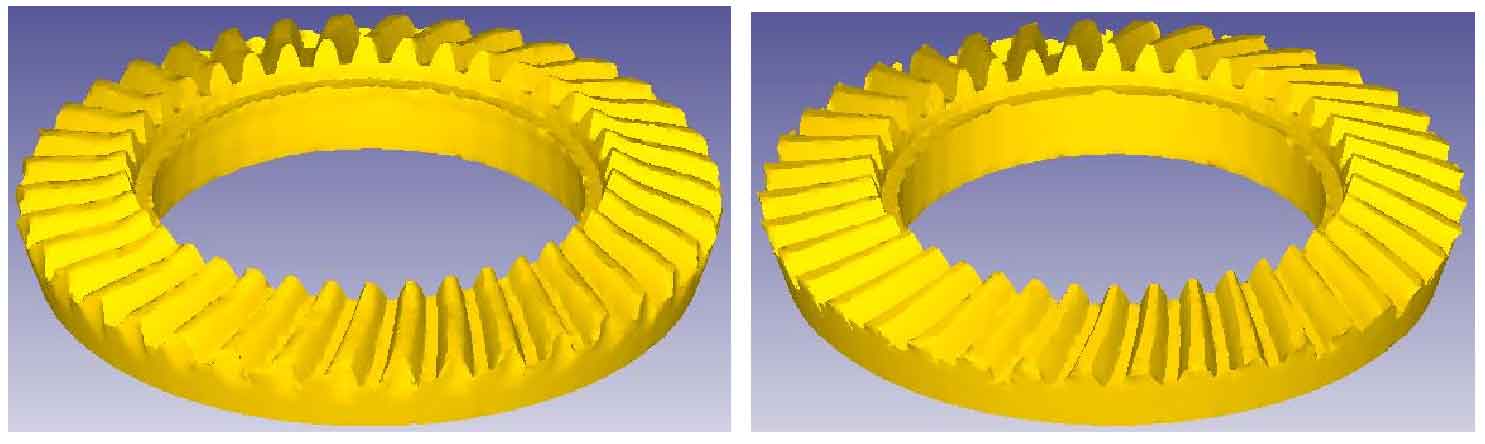

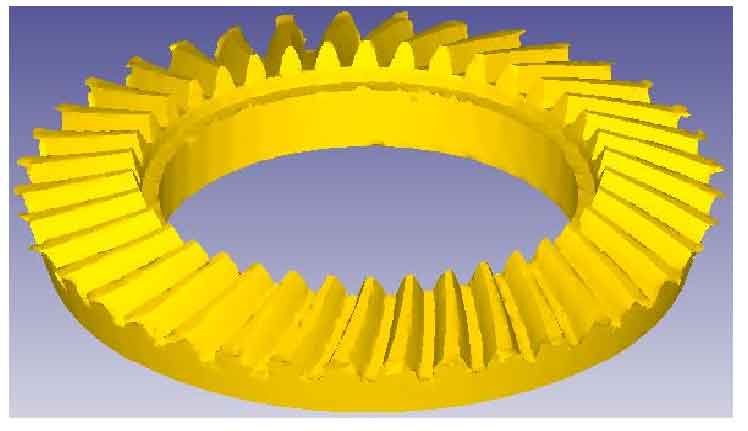

Figure (a) in Figure 2 shows the shape of the spiral bevel gear blank when the stroke is 0, and figure (b) shows the shape of the spiral bevel gear blank when the stroke is 2.7 mm. It can be seen from the figure that in this process, with the downward movement of the upper die, the tooth shape part of the upper die is gradually pressed into the spiral bevel gear blank, causing the blank to deform and form an indentation on the spiral bevel gear blank; When the stroke of the upper die is from 2.7 to 11 mm, the load increases with the increase of the stroke, but the increase is relatively slow. Figure (c) in Figure 2 is the shape diagram of the spiral bevel gear blank when the stroke is 11 mm. It can be seen from the figure that the deformation in this process is mainly upsetting deformation, accompanied by a small amount of metal flowing into the tooth shaped cavity, but the metal in the cavity is not full, and the load changes smoothly; When the stroke of the upper die is from 11 to 12.3 mm, the load increases rapidly until the maximum load is reached, and the maximum load is 15800 kn. Figure (d) in Figure 2 is the shape diagram of spiral bevel gear blank when the stroke is 12.3 mm. It can be seen from the figure that the main deformation in this process is the forming process of tooth profile, which becomes more flat and smooth under the action of large load, Because in this process, the cavity of the spiral bevel gear has been filled, the internal space is small, the metal flow is difficult, the deformation resistance of the extrusion blank when the upper die moves down increases rapidly, and the friction between the metal and the spiral bevel gear blank also increases, so the load increases rapidly with the increase of the stroke; During the process from the stroke of the upper die to the final processing, the load fluctuates up and down. Figure (E) in Figure 2 is the shape diagram of the pre forging. It can be seen from the figure that the main deformation in this process is that the excess metal flows into the flash groove to form the flash. In this process, the metal flows into the flash groove along the tooth shape direction under the action of pressure, making the load float up and down, but its value changes little.