Equivalent strain refers to the strain equivalent to unidirectional strain formed by the appropriate combination of various strain components in the general strain state, also known as generalized strain or strain strength, so equivalent strain is mainly used to describe the deformation of blank.

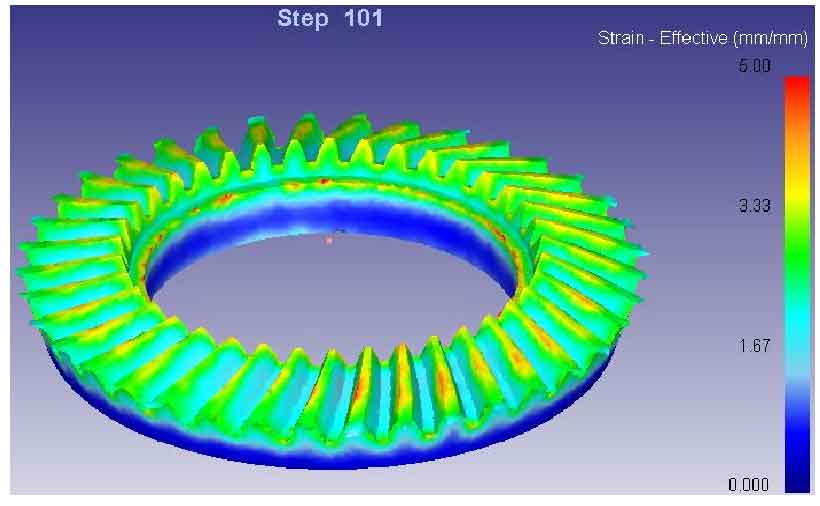

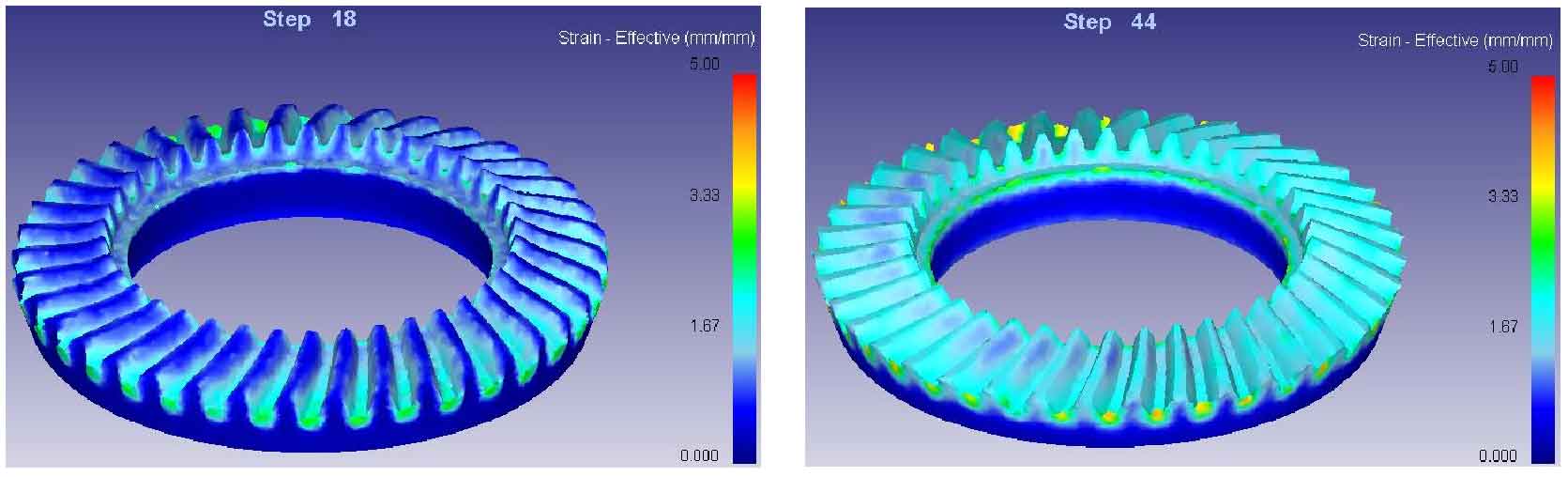

The figure shows the distribution of equal effect variation at different strokes in the warm precision forging process of spiral bevel gear. Figure (a) is the distribution diagram of equal effect variation when the stroke is 11 mm, figure (b) is the distribution diagram of equal effect variation when the stroke is 12.3 mm, and figure (c) is the distribution diagram of equal effect variation in the final step. The whole gear can be divided into two parts for research according to the equal effect variation distribution diagram. With the increase of the stroke of the upper die, the equal effect variation of the upper part (tooth shape part) of the gear gradually increases, which is called the large deformation area; The equivalent deformation of the lower part of the gear is basically unchanged, which is called small deformation area.

(b) Equivariant distribution with a stroke of 12.3 mm

In the whole forming process, the area with larger medium effect is mainly concentrated in the large deformation area, that is, the part of tooth profile. For the whole forming process, the billet has axial strain under the downward extrusion of the upper die; During upsetting, the metal flows radially from the small end of the gear to the large end of the gear, resulting in radial strain; In the forming process of the tooth profile, the metal flows along the tooth cavity of the upper die. Due to the existence of the helix angle of the driven spiral bevel gear of the automobile rear axle, the radial strain will be accompanied by the tangential strain at the same time.

Therefore, the strain in the warm precision forging process of the driven spiral bevel gear of the automobile rear axle is very complex. It can be seen from the figure that the equivalent strain of the final step reaches the maximum, and the maximum equivalent strain is only 3.5 mm / mm, which is relatively small. It is proved that the warm precision forging of the driven spiral bevel gear of the automobile rear axle is feasible and has high practicability.