The forming quality of forgings directly determines the quality and service life of products. The surface finish of the straight bevel gear blank after hot die forging is not good and the dimensional accuracy is low. Therefore, it is necessary to carry out cold precision forging on the straight bevel gear blank after removing the surface oxide skin, so as to improve its dimensional accuracy and forming quality and make it meet the technical requirements of the final product.

If the tooth shape of cold precision forging preform of spur bevel gear is not designed properly, it will not only lead to metal folding and other defects due to unreasonable metal flow, but also seriously affect the service life of cold precision forging die. In conclusion, it has far-reaching practical significance for the tooth shape optimization of cold precision forging preform of spur bevel gear.

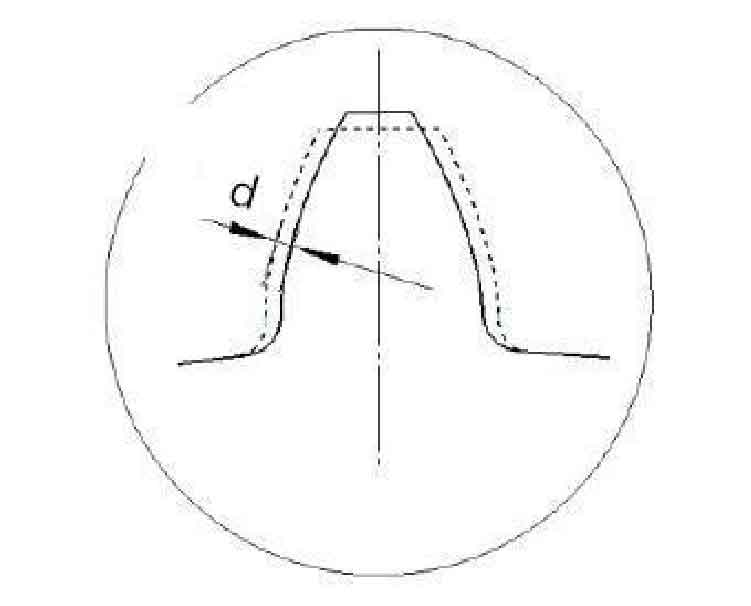

The uniform diffusion tooth profile scheme is based on the cold forging drawing, and the tooth profile is evenly extended outward according to the cold precision forging quantity; Then shrink the dimension of the tooth tip circle radially to make the forging conform to the tooth profile scheme of the equal volume principle. The figure shows the schematic diagram of uniform diffusion tooth profile scheme. The solid line in the figure is the tooth shape of cold precision forging die, the dotted line is the tooth shape of cold precision forging preform, and D represents the cold precision forging amount (mm). At present, only similar schemes have been used to study the tooth profile design of cold precision forging preform of spur bevel gear, and it is concluded that when the cold precision forging amount is large, the tooth root of spur bevel gear will fold to varying degrees, while when the cold precision forging amount is small, the forming effect of forging tooth surface will be reduced. Firstly, the uniform diffusion tooth profile scheme is tried to be used in the cold precision forging process of spur bevel gear.

In order to study the influence of uniform diffusion tooth profile of different sizes on the cold precision forging process of driven spur bevel gear, three schemes are formulated, as shown in the table:

| Scheme I | Scheme II | Scheme III | Scheme IV | |

| Cold precision forging amount of tooth surface D / mm | 0.1 | 0.2 | 0.4 | 0.8 |