Because there are many and complex influencing factors in the milling process, there is no theoretical formula to directly calculate the cutting force in each direction. The usual method is to conduct a large number of experiments to obtain empirical formulas. In the empirical formula of cutting force, the three main factors of cutting speed, feed rate and milling depth are usually taken as variable factors, and other factors are taken as correction factors. For sharp milling tools, the force on the rake face is the main force, and the force on the rake face is relatively small and can be ignored. The load applied in the static and dynamic analysis of the machine tool is the main cutting force.

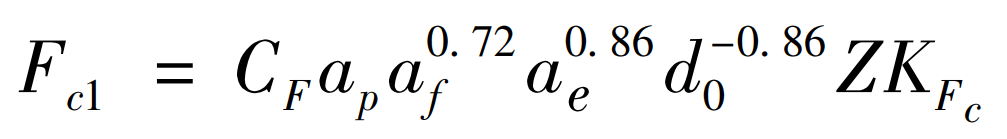

Taking the gear to be processed with modulus m of 6, number of teeth Z of 18 and material of 40Cr as the processing object, the gear blank is processed with 8-tooth milling cutter. Calculate the main cutting force FC1 according to the common empirical formula:

Where, CF is the milling force coefficient; AP is the milling depth; AF is the feed rate of each tooth; AE is the milling width; D0 is the diameter of milling cutter; Z is the number of milling cutter teeth; KFC is the milling force correction factor.

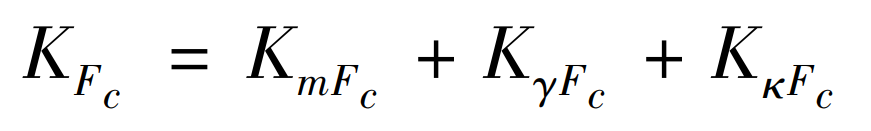

The milling force correction coefficient KFC:

Where, kmfc is the material coefficient of the workpiece; K γ FC is the front angle coefficient; K κ FC is the main deflection coefficient.

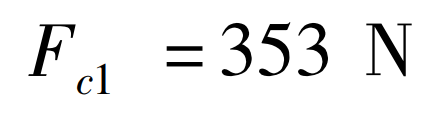

When checking the milling parameters in the practical machining process manual, considering the actual situation of machining and forming of variable hyperbolic arc gear, take the appropriate parameters AP = 3 mm, AE = 60 mm, AF = 0.02 mm / Z, substitute each parameter into the formula, and calculate the main cutting force FC1:

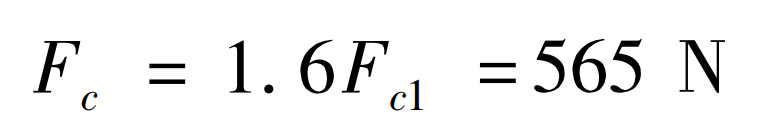

The limit cutting force is one of the important parameters characterizing the processing capacity of the equipment, and its size is about 1.6 times of the main cutting force. Finally, the applied main cutting force FC:

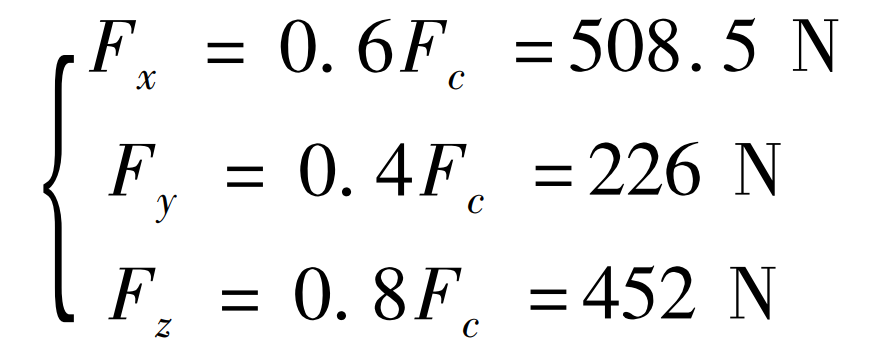

During milling, the milling force on the gear blank can be decomposed into three components along the X, y and Z directions of the equipment: X-direction feed component FX, Y-direction feed component FY and Z-direction feed component FZ, so as to apply load. The empirical ratio of each component force to the applied main cutting force during forward milling is: