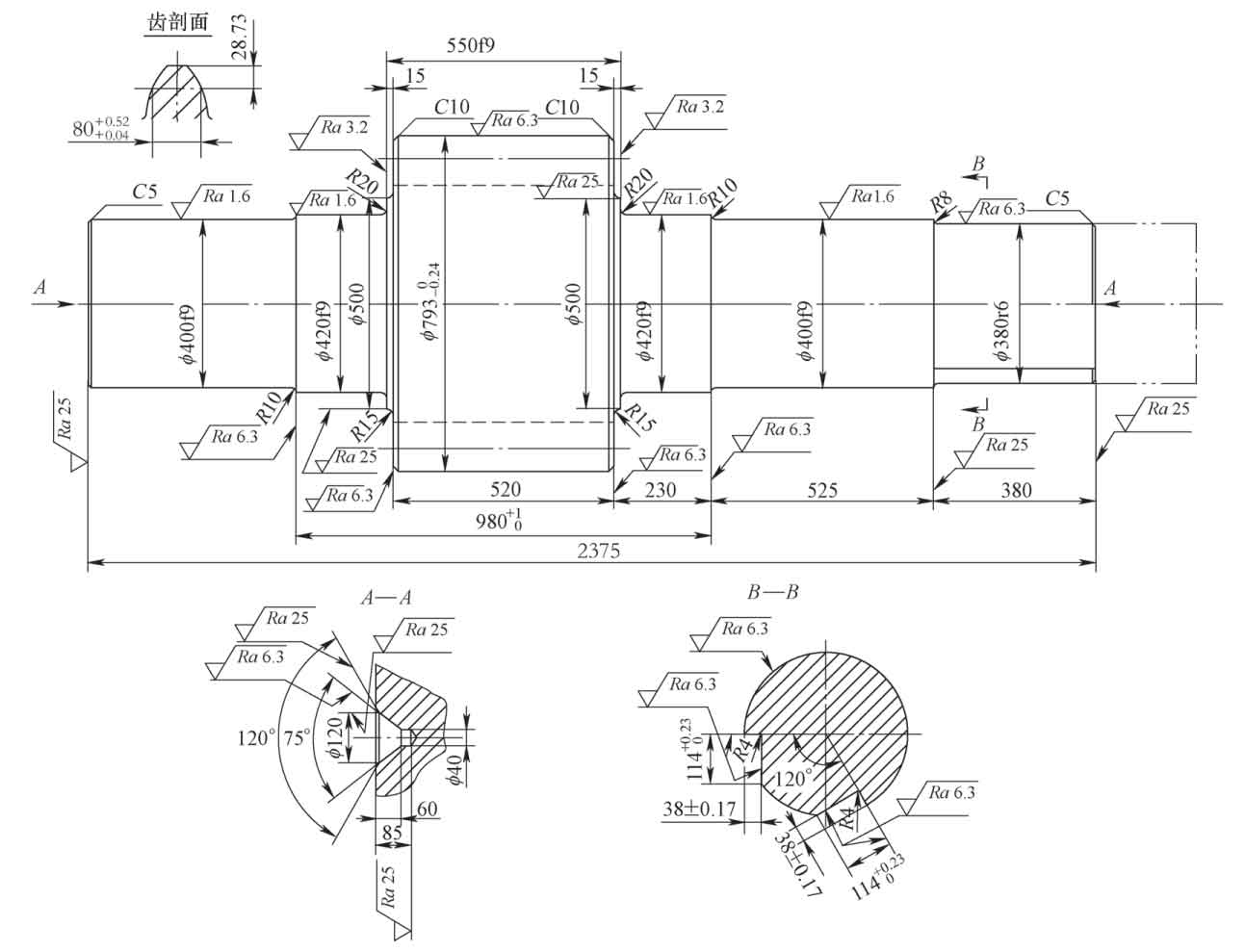

The gear shaft with modulus of 65mm (see Figure) is one of the key parts in the transmission mechanism of 900t or 1300T mixer furnace, and it is also the gear shaft with the largest modulus processed by the company in history. Because the processing range of the existing hobbing machine or gear shaper of the company can not meet the processing requirements of parts, the generation method can not be used for processing, but the forming method can only be used for processing. Before that, the modulus of the largest gear shaft processed by the company was 50mm, which is to use the formed finger milling cutter to process single teeth on the boring and milling machine, and use the dividing head to divide according to the number of teeth to complete the processing of all tooth profiles.

Because the gear module is large and the cutting length of the tool is large, the cutting force increases. In the process of machining, the power of the machine tool can basically meet the use requirements. Because the tool speed is not high, the surface roughness of the machined tooth surface is lower than the design requirements. According to the use of the gear shaft, as long as the fitter polishes the tooth surface and improves the surface quality of the tooth surface, it can fully meet the use requirements.

According to the machining experience of gear shaft tooth profile with module of 50mm, the machining of gear shaft tooth profile with module of 65mm can not be completely in accordance with the above method. There are two reasons: first, the power of the machine tool is insufficient; Second, the cutter has large volume and large quality, and the connection rigidity between milling cutter and cutter base, cutter base and spindle cannot be guaranteed. In order to process the tooth profile of this large module gear shaft on the boring and milling machine, effective measures must be taken to solve the above two problems: first, reduce the tool quality; The second is to increase the connection rigidity between milling cutter and cutter base, cutter base and spindle. Only in this way can the tooth profile machining of the gear shaft be completed.

Referring to the structure of the gear shaft and according to the design requirements and application of the gear shaft tooth profile of 900t mixer furnace, the above problems can be effectively solved by adopting the method of processing a complete tooth profile with two milling cutters in three times.