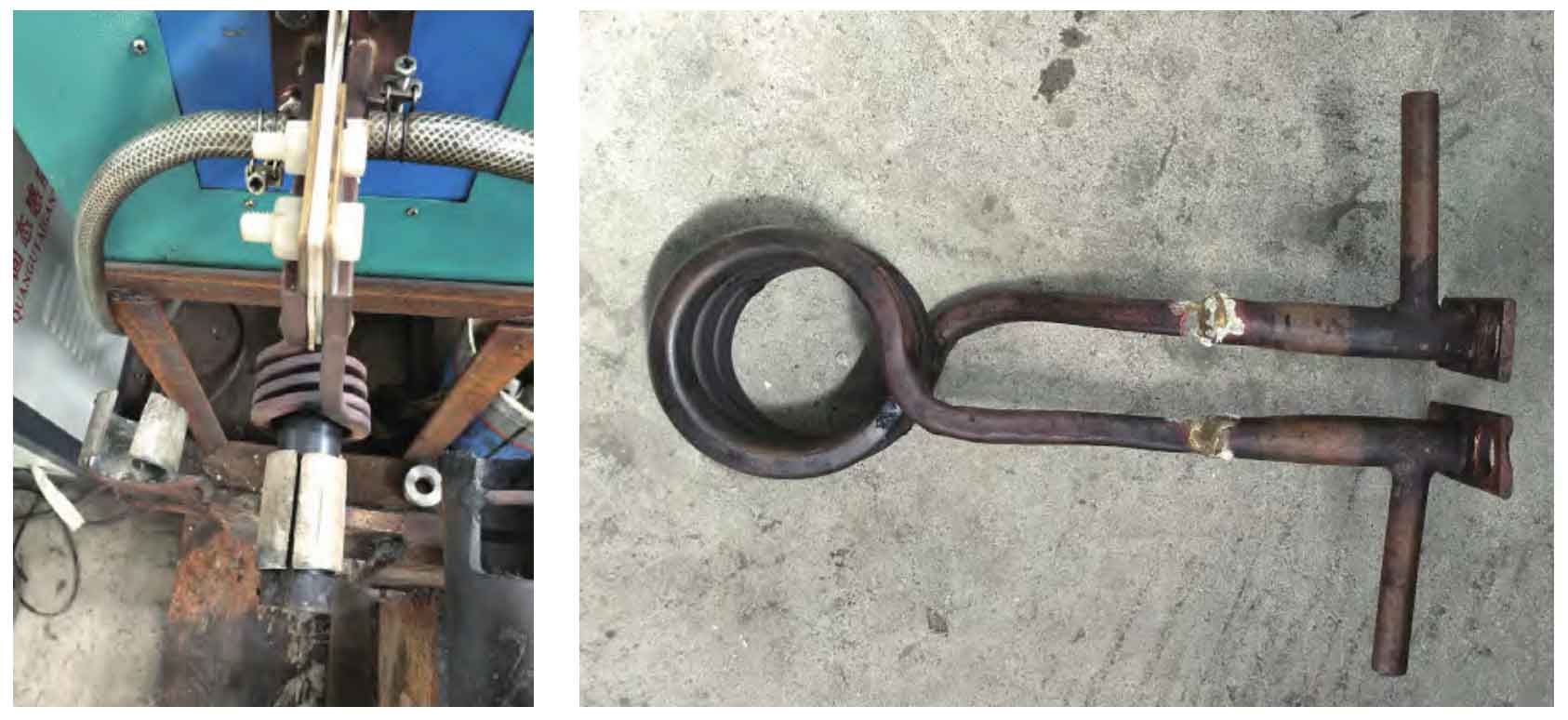

The supplier has a solid-state heating equipment with a water temperature of ± 10.38 ~ 30 kHz and a water temperature of ± 10.38 ℃ for induction treatment, and a water temperature of 10 ~ 30 ℃ for induction treatment. The commissioning status during induction operation is shown in Figure 1, and the induction ring is shown in Figure 2.

There were two quality problems in the initial stage of induction annealing trial production of spiral bevel gears: first, the external thread area requiring induction annealing was manually sent into the induction ring for heating annealing, resulting in poor stability of hardness index after annealing; Second, the induction heating parameters are not well controlled, which leads to the increase of hardness of some spiral bevel gears after induction annealing. For this reason, the factory and the sub supplier have carried out the improvement of the operation process together.