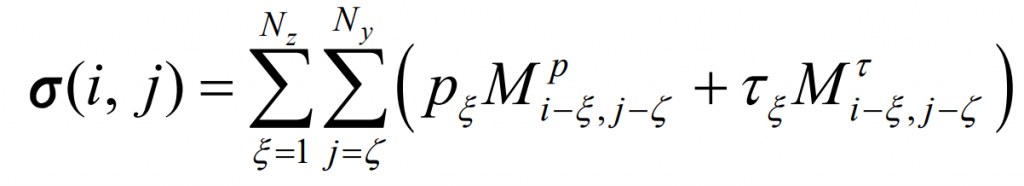

Based on the pressure and shear stress at the meshing interface of cylindrical gear obtained from the above analysis, the stress can be calculated by the following formula:

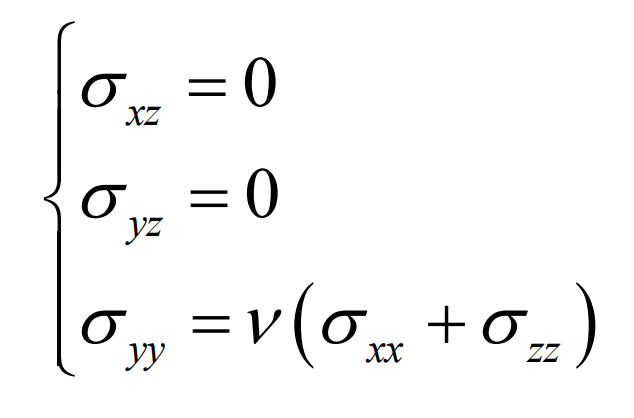

Where MP is the influence factor of pressure stress, M τ As the influence factor of friction stress, discrete convolution fast Fourier transform is used to speed up the calculation. It should be noted that this model is based on the two-dimensional plane strain problem, and the stress-strain relationship is as follows:

among ν Is Poisson’s ratio.

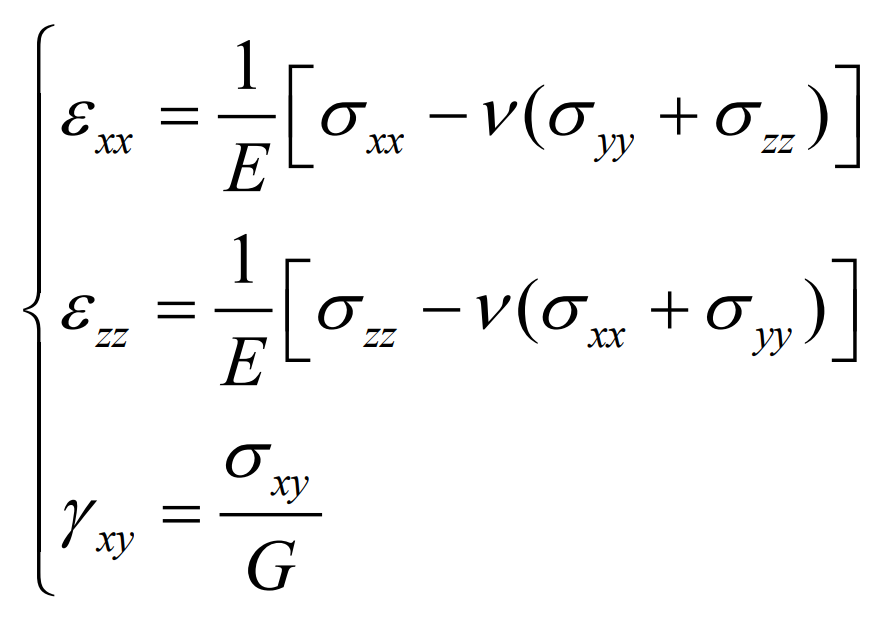

The strain can be calculated from the stiffness matrix of isotropic material, and the formula is as follows:

Where G is the shear modulus.

It should be noted that the solution of the current time step in EHL modeling depends on the solution of the previous time step or the first two time steps, which is independent of the coordinate position. In this paper, the fixed coordinate origin is the node position. Considering that the linear speed of the two cylindrical gears basically changes linearly, the average speed between the current point and the node and the time interval between the current cylindrical gear meshing point rotating to the node or the node rotating to the current cylindrical gear meshing point are solved to determine the distance between the current cylindrical gear meshing point and the node position, Calculate the stress / strain in the calculation area under the current cylindrical gear meshing state.