The structural parameters and test parameters of spur gear are as follows: the material of spur gear is 20CrMnTi, the modulus is 5 mm, the pressure angle is 20 °, the pinion is 24 teeth, the big gear is 26 teeth, the tooth width is 21 mm, the surface accuracy is grade 6, and the working conditions are set as follows: the speed is 1200 R / min and the torque is 1000 nm. According to the dynamic analysis of spur gear meshing theory, the load in double tooth meshing area increases linearly from 0.27 kn / mm to 0.54 kn / mm, or decreases linearly from 0.54 kn / mm to 0.27 kn / mm, and the load in single tooth meshing area is always 0.81 kn / mm.

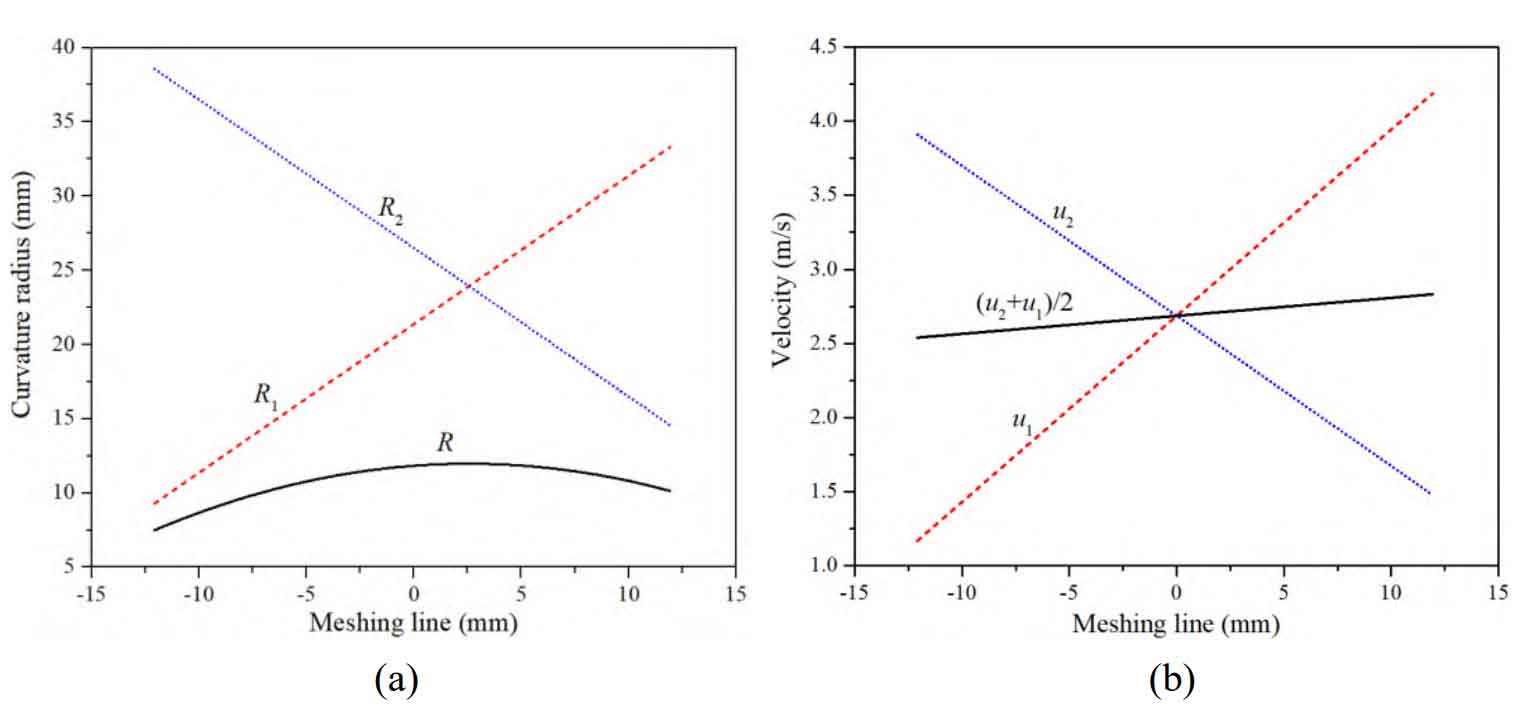

The equivalent curvature radius of each meshing position and pinion, as well as the meshing speed of each meshing position and pinion and the entrainment speed of lubricating oil are shown in the figure. It should be noted that the determination of load, curvature, speed and other parameters does not consider the errors caused by spur gear manufacturing, modification and installation, and ignores the impact caused by tooth meshing in and out during spur gear meshing.

However, the research shows that the fatigue pitting corrosion of spur gear mainly occurs near the node, and the load before and after the point is constant, and the transient lubrication behavior in the nearby area is not obvious. Therefore, the simulation based on the load distribution of quasi-static transmission and the complete involute contact characteristics can still provide a more accurate evaluation for the fatigue of spur gear.