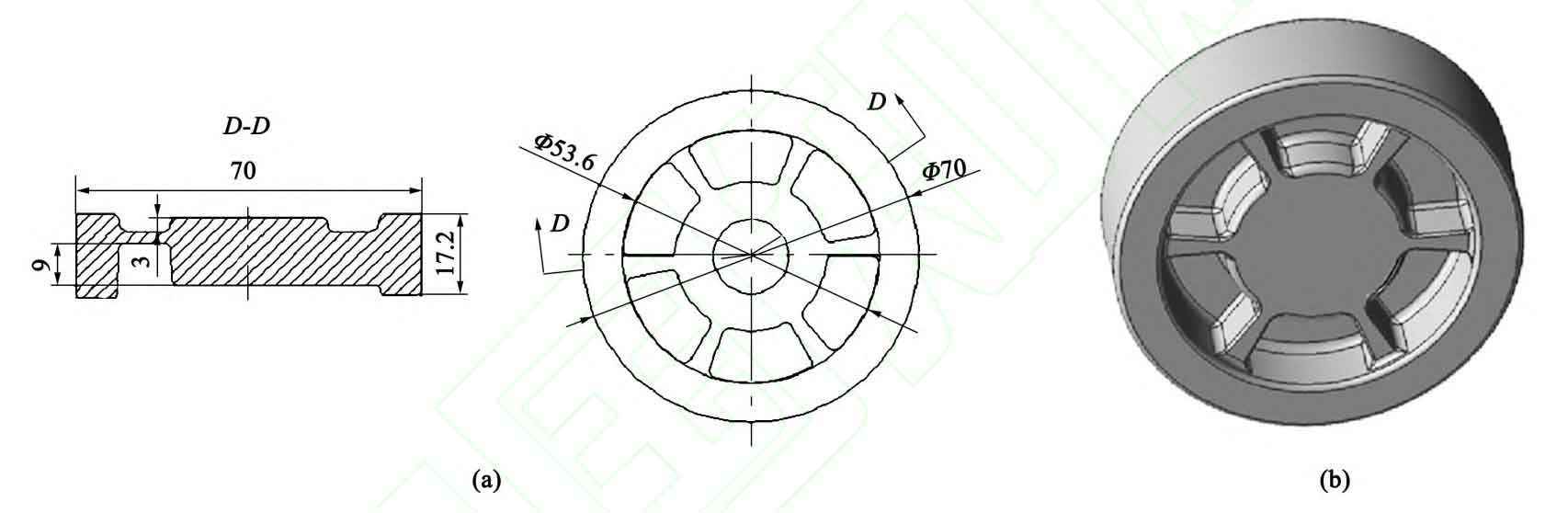

The research object is the gear, which is an important transmission component of motor vehicles. Its quality defects will seriously affect the service life and safety of vehicle power system. The gear is forged and processed through a few subsequent processes. The forging is shown in Figure 1.

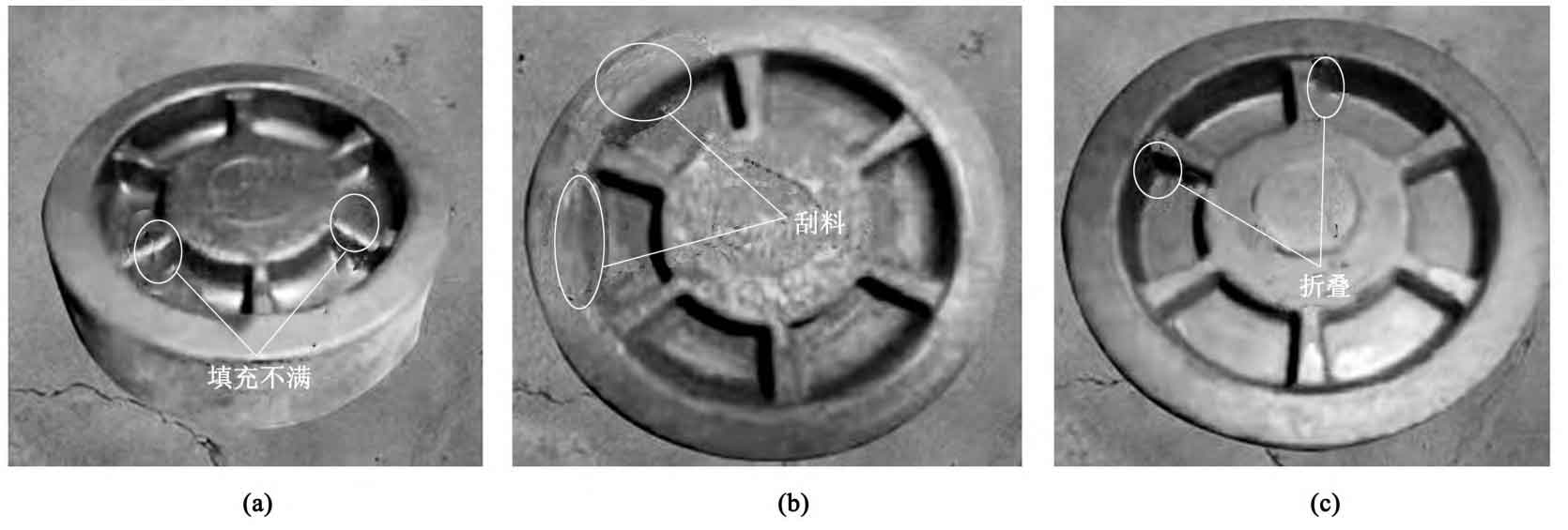

Due to the complexity of the structure of the gear itself and the backwardness of the forming technology, there will be defects such as insufficient filling, folding and scraping when the gear is forged directly, as shown in Figure 2. Therefore, the method of pre forming first and then final forging is used, and the forging pre forming process of gear is optimized.