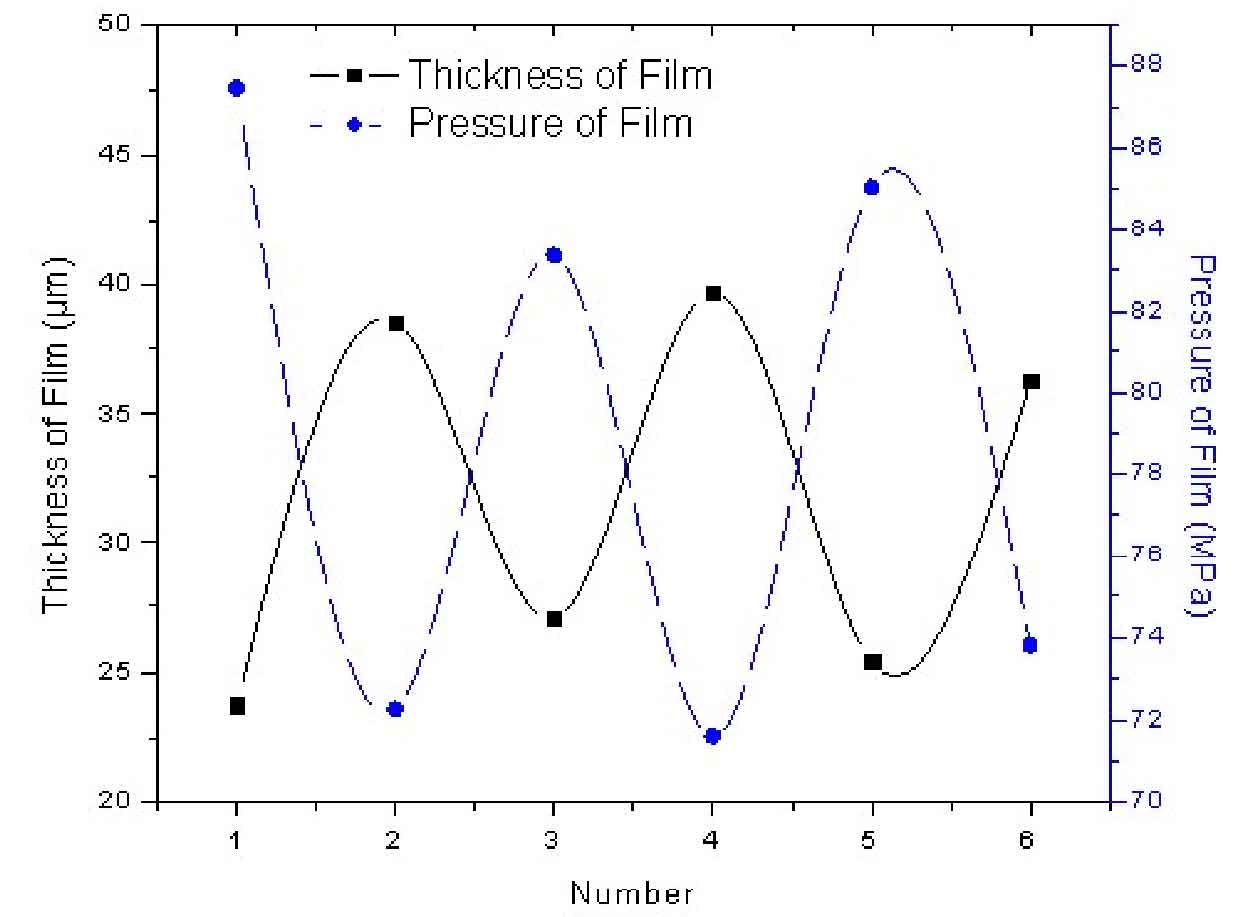

Using five basic equations and MATLAB software for numerical calculation, select six contact points in the direction of gear tooth contact width (evenly distributed along the gear tooth meshing line, with both concave contact points and smooth contact points), and calculate the numerical relationship between the contact oil film thickness and oil film pressure of concave cylindrical gear, as shown in the figure:

Through numerical calculation, it can also be concluded that the oil film thickness of 1-6 points of concave bionic cylindrical gear is 23.75 µ m, 38.58 µ m, 27.03 µ m, 39.69 µ m, 25.41 µ m and 36.22 µ m, and the corresponding oil film pressure is 87.450mpa, 72.257mpa, 83.369mpa, 71.618mpa, 85.072mpa and 73.806mpa respectively. As can be seen from the figure, the oil film thickness is also very thin, and the oil film thickness is inversely proportional to the oil film pressure; However, compared with the numerical calculation results of elastohydrodynamic lubrication of smooth cylindrical gears, the oil film thickness between the contact surfaces of concave bionic cylindrical gears is significantly greater than that of smooth cylindrical gears, and the corresponding oil film pressure is less than the calculation results of smooth cylindrical gears, indicating that there is a thick oil film gap in the contact surface area of concave bionic cylindrical gears under lubrication, which can reduce the oil film pressure between cylindrical gears, That is, the contact stress of direct contact of cylindrical gears is reduced. In the table, the average oil film thickness of the concave bionic cylindrical gear (31.78 µ m) is greater than the contact film thickness of the smooth cylindrical gear (14.88 µ m), and the corresponding average oil film pressure (78.929mpa) is also less than the average oil film pressure between the smooth cylindrical gears (94.758mpa).

| Element | Contact point 1 | Contact point 2 | Contact point 3 | Contact point 4 | Contact point 5 | Contact point 6 | Average thickness Average pressure |

| Oil film thickness µM | 23.75 | 38.58 | 27.03 | 39.69 | 25.41 | 36.22 | 31.78 |

| Oil film pressure Mpa | 87.450 | 72.257 | 83.369 | 71.618 | 85.072 | 73.806 | 78.929 |