Ring rolling module is a special module of DEFORM-3D to simulate spur gear ring rolling process, which is a method based on ale. This finite element method is very useful. It is specially designed for ring rolling research. This new subroutine generation greatly reduces the calculation time (calculated in days instead of weeks). The model adopts hybrid grid, in which hexahedral element is used to divide the edge of the ring, while tetrahedral element is used to divide the cross section, and rigid plastic blank model is used to improve the calculation accuracy. The criterion of remeshing is to reduce the distortion of the mesh and maintain high-quality mesh in the simulation process. Another important aspect is related to the stability of spur gear ring rolling process. Asymmetric deformation may occur on the workpiece during spur gear ring rolling, which will lead to continuous changes of the rotating shaft. Generally, in actual industrial production, a group of guide rollers are placed to center and maintain the roundness of the ring. However, the ring rolling module has self centering function, so it can be simulated without guide roller. In addition, due to the characteristics of the spur gear ring rolling module, a symmetrical model can be used to reduce the number of grids and calculation time.

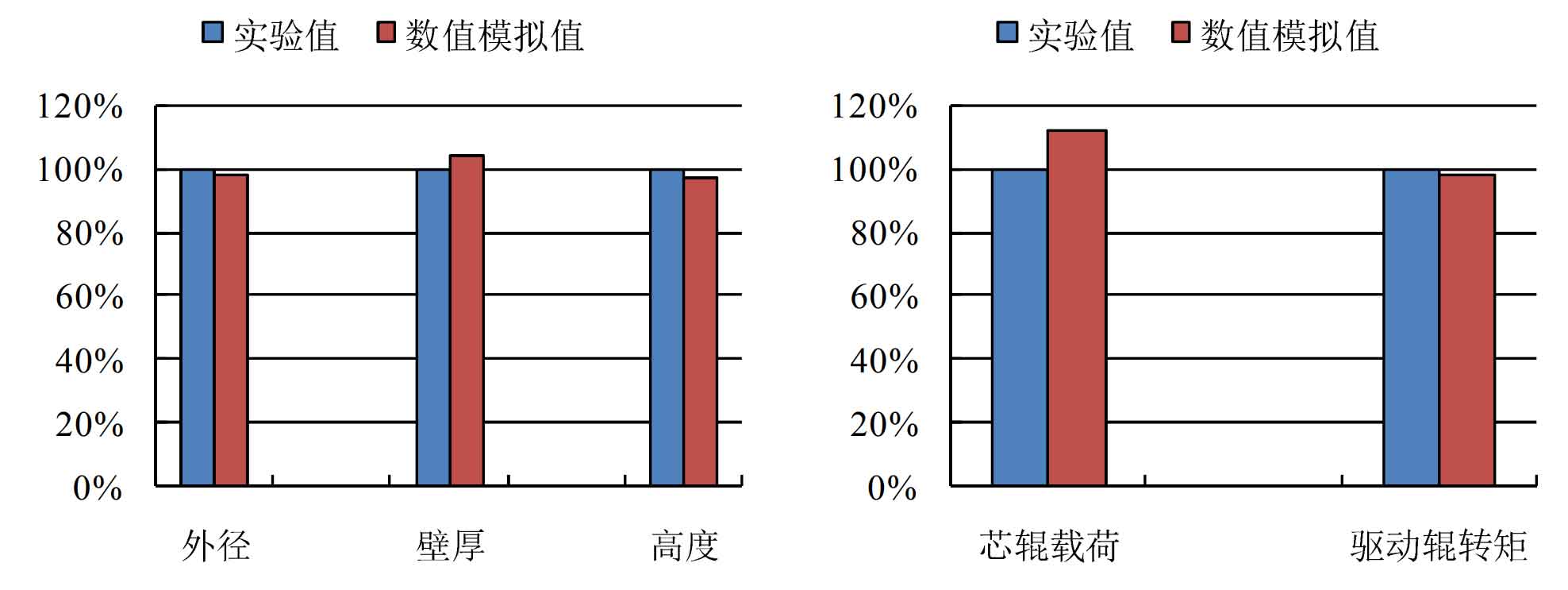

In order to determine the reliability level of the numerical method model, it is necessary to compare the experimental value with the numerical simulation value. In previous studies, ceretti E and others tested the reliability level of the numerical simulation model by comparing the test results with the simulation results. The accuracy analysis of finite element method is based on the double comparison of geometry and physics. A better conclusion is obtained by comparing the experimental and numerical analysis results. In order to make the results more significantly independent of the simulated values, all values in the figure are expressed as percentages, and the test value is equal to 100%. The closer the numerical simulation value is to 100%, it shows that the numerical model has higher accuracy and reliability.

It can be seen from the figure that the ring rolling module can be used to predict the straight gear ring rolling process because of the high accuracy of the software, which is mainly reflected in that the final dimension deviation of the ring is less than 5%, and the maximum load and torque deviation required by the straight gear ring rolling is less than 15%.