Swing rolling, namely swing rolling, also known as axial rolling. It first appeared in the s. It was not until the Polish marzinnik developed the four track cold forming swing rolling machine in the early s that it was really put into production and application as a process technology.

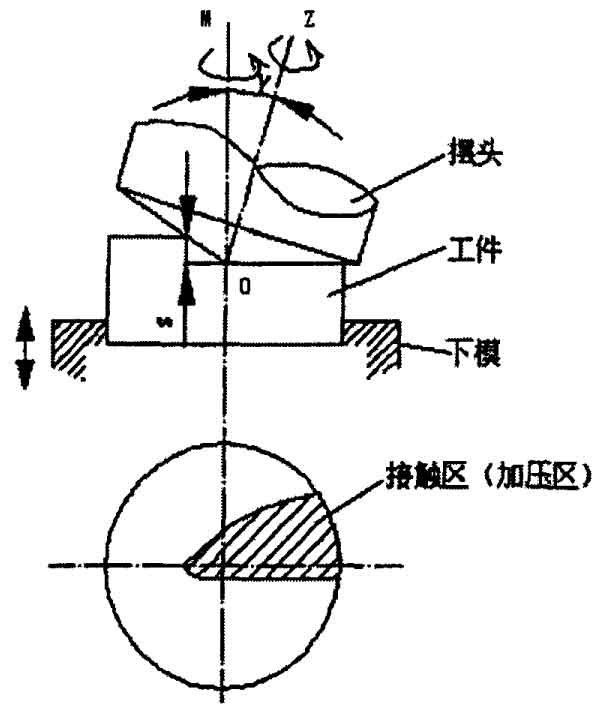

The figure is the schematic diagram of swing rolling. The swing rolling process has the following characteristics:

- The rotary rolling die has two parts: the upper die (swing head) and the lower die. Compared with other forms of pressure processing methods (general forging, stamping, extrusion, drawing, rolling, spinning, cross rolling \ roll forging, cross wedge rolling, rotary forging, ring rolling, etc.), the relative movement between dies is much more complex. The movement of the upper die can be divided into: rotation around its own axis + swing around the main shaft of the equipment; The lower die moves upward along the main shaft of the equipment.

- In the process of rotary forging, there is always local contact between the swing head and the blank. As shown in the figure, the center line oz of the swing head intersects with the center line om of the machine spindle γ This angle is called swing angle. When the spindle rotates, oz rotates around OM, and the upper die swings. At the same time, the lower die rises under the action of the oil cylinder and puts pressure on the blank, so that the upper die bus will roll continuously on the blank, and finally achieve the purpose of overall forming. It is equivalent to the cone rolling + sliding on the workpiece along the bus, and the contact surface is biased to one side, that is, the machine tool bears periodic deformation eccentric load. The contact area between the swing head and the blank is 1 / N (n = 5-10) times of the overall projected area, and the deformation force is only 1 / N of the original.

- Compared with the traditional plastic processing method, the motion tracks of rotary rolling processing are diverse, including circle, straight line, spiral line, chrysanthemum line (i.e. multi leaf rose line with intersecting leaves), multi leaf rose line (multi leaf rose line with intersecting leaves, etc.). Different trajectories are applicable to parts with different features.

- Rotary forging process is mainly applicable to forming axisymmetric parts.