So far, great progress has been made in the research of swing rolling theory all over the world, such as the calculation of contact area ratio, the calculation of deformation force and the theoretical analysis of stress and strain. However, due to the complexity of rotary rolling deformation and the difficulty of research, people have not formed a regular understanding of its deformation mechanism, and there are some basic problems to be solved by further research, such as the law of uneven deformation of rotary rolling and the theory of particle velocity field in workpiece. Especially for the swing rolling deformation of straight bevel gear, the shape of straight bevel gear is complex and the accuracy requirements are high. In order to carry out high-precision finite element simulation of the swing rolling process of straight bevel gear, we also need to consider the elastic deformation of the die and reasonable friction coefficient.

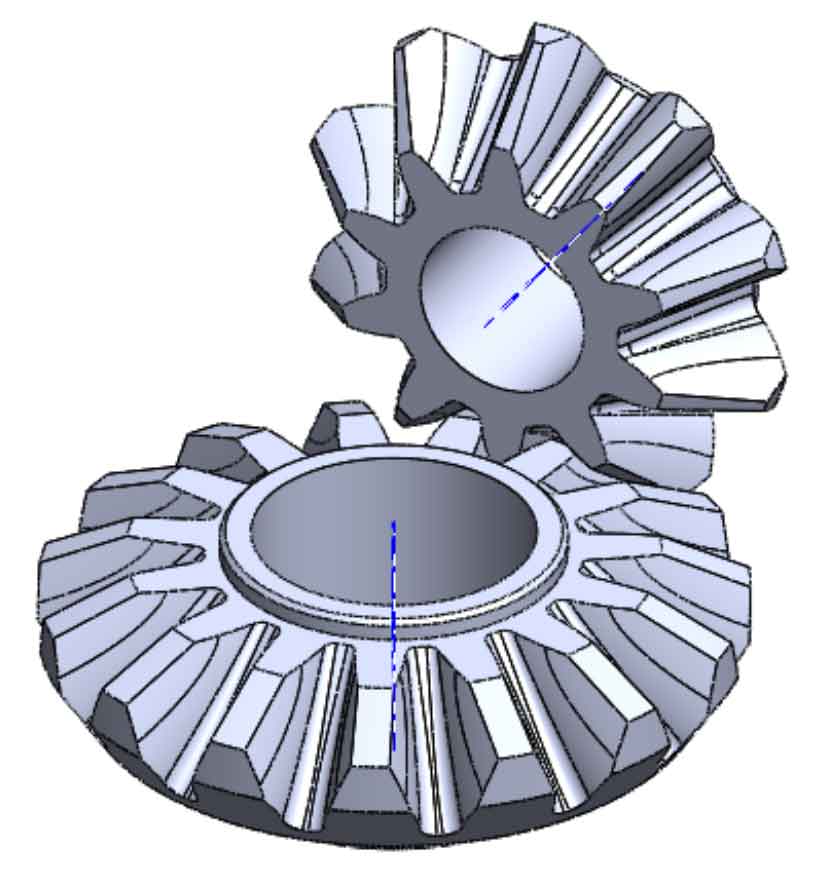

Rotary forging has achieved the goal of integral forming through continuous local repeated extrusion, so its metal flow law is much more complex than simple forging. Straight bevel gear is the most widely used part to transmit motion and power in automobiles, ships and all kinds of machinery. The cold precision forging of straight bevel gear using ferrous metal is a hot research issue at home and abroad. However, there is relatively little research on the swing rolling forming of straight bevel gear. Therefore, the research on the swing rolling forming of straight bevel gear can enrich the swing rolling process theory of straight bevel gear. At the same time, it has direct guiding significance for the actual production of this part and the actual production of similar parts. It can effectively reduce the actual test The number of tooling and dies can effectively reduce the production cost and improve the production efficiency.