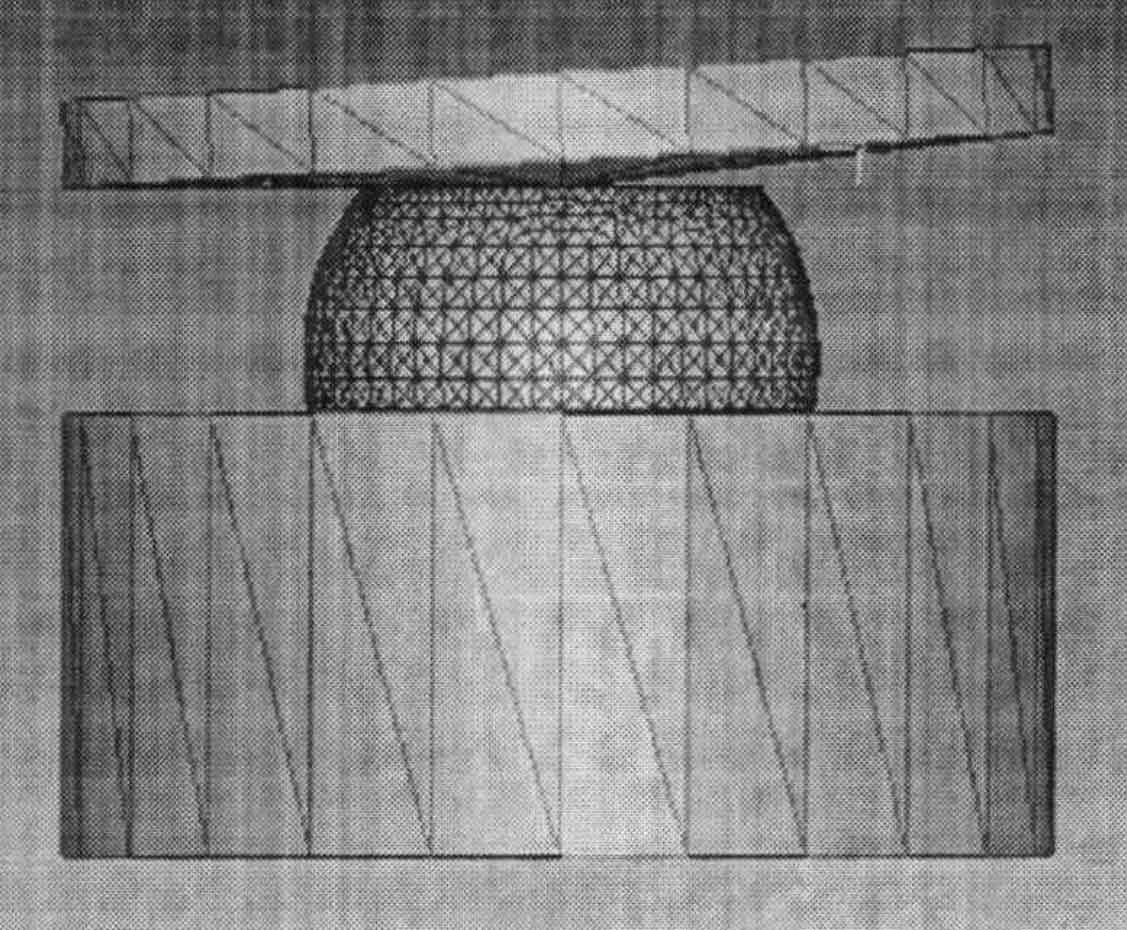

According to the actual situation in the production and experiment of rotary forging of spur bevel gears, in order to facilitate the finite element analysis and calculation and ensure high accuracy. The following basic assumptions are made: the die is set as a rigid body, the material simulating the blank is regarded as a rigid plastic strain hardening material, the temperature effect in deformation is ignored, and the friction boundary conditions are applied according to the constant shear factor friction model. The established finite element model is shown in the figure.

The tetrahedral isoparametric element is used to divide the cylindrical spur bevel gear blank, and the mesh is redrawn according to the mesh distortion at any time in the calculation, so as to ensure the accuracy and convergence of the calculation. The swing of the upper die is realized by the combination of revolution and rotation, and the vertical downward feed speed is applied to the upper die to realize the swing rolling movement of spiral screwdown.

| Name | Value |

| Feed rate per revolution / mm | 5 |

| Friction factor / m | 0.12 |

| Swing head inclination / (°) | 3 |

| Swing head speed / (r/min) | 298 |

In rotary forging, there are many factors affecting the quality and size of spur bevel gear. The focus is to analyze the influence of the shape and size of spur bevel gear blank on the filling quality. The initial conditions adopted are shown in the table.