As an analysis method in the process of metal plastic forming, numerical simulation does not need to build physical models, so it saves a lot of manpower, material resources, financial resources and time. Numerical simulation before production can reduce a large number of production tests, so as to reduce the processing of test molds and shorten the design time and production cycle. Numerical simulation can evaluate different schemes in time and select the best scheme in the design stage. With the development of computer technology and plastic forming theory, numerical simulation method is more and more widely used in the simulation and analysis of metal forming process.

From the results, we can know that the spur gear drum blank is most conducive to the forming of spur bevel gear. Therefore, on the basis of the above, we further study the optimization of spur gear drum blank.

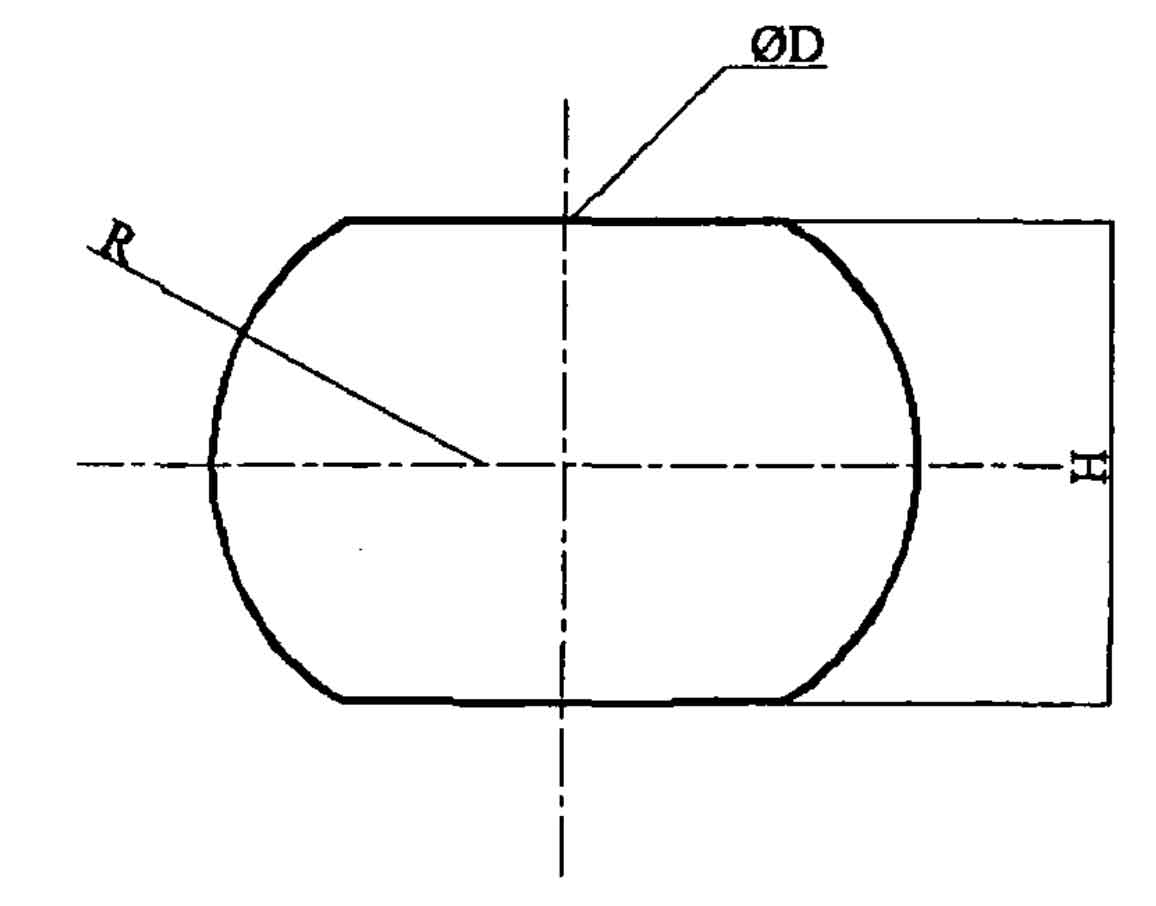

The schematic diagram of spur gear drum blank is shown in the figure. There are four blank shape parameters: upper and lower bottom diameter D, height h and drum radius R. Take the following settings for research:

(1) Same volume;

(2) The upper and lower bottom diameters are the same, and a certain value of 18.5mm is taken;

(3) Design a parameter α= H / R to represent drum shape and drum degree.

Therefore, in the following content, we mainly study the influence of drum degree on spur gear forming. There are many different values of drum shape and drum degree. Six drum degrees are selected for analysis α They are 0.89, 0.92, 1.06, 1.25, 1.68 and 1.90 respectively.