The forging process of gear blank under different initial forging temperature and different friction coefficient is studied. The forging temperature is 1000 ° C, 1050 ° C and 1100 ° C respectively, and the friction coefficient is 0.3 (with lubrication, i.e. lubricant is used in the forging process) and 0.7 (without lubrication). The blank forging process is numerically simulated, and the effects of initial forging temperature and friction coefficient on forming effect are analyzed.

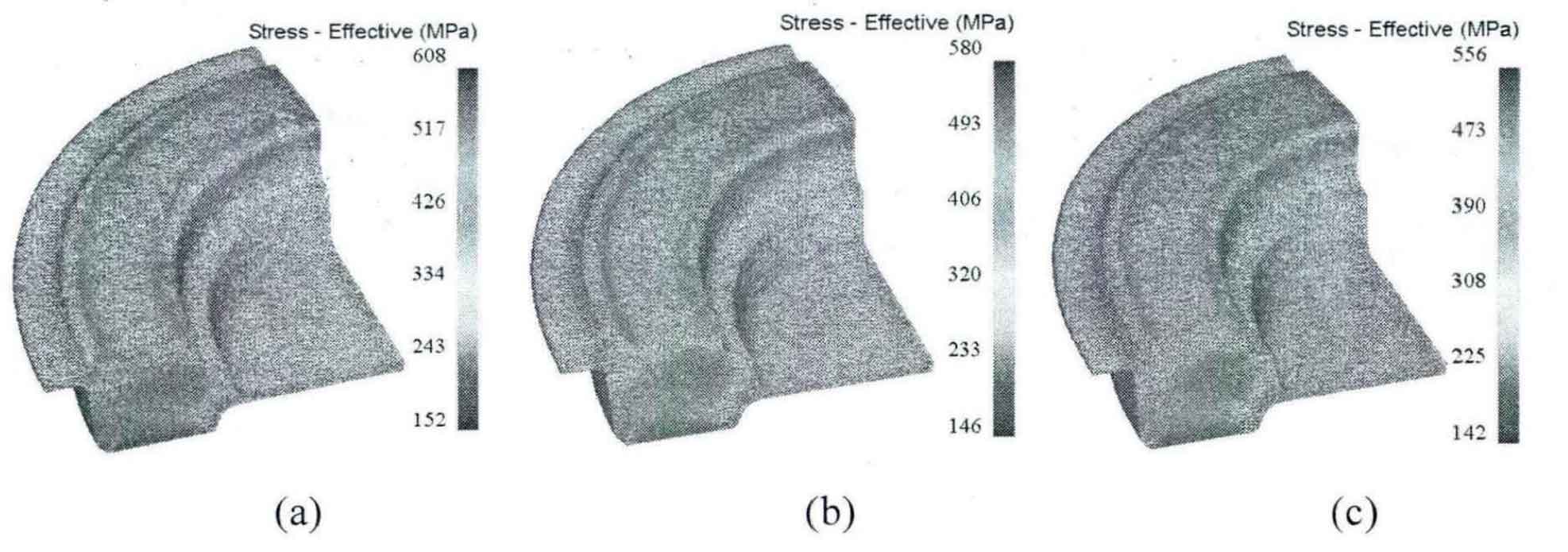

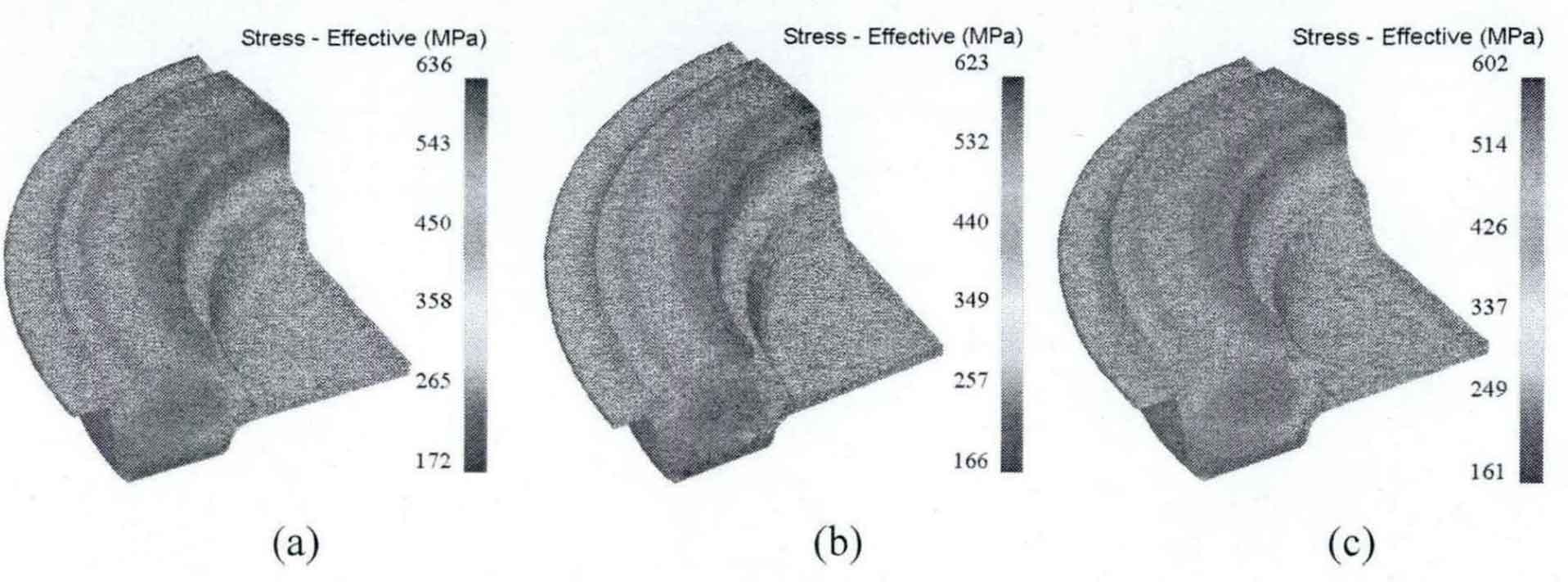

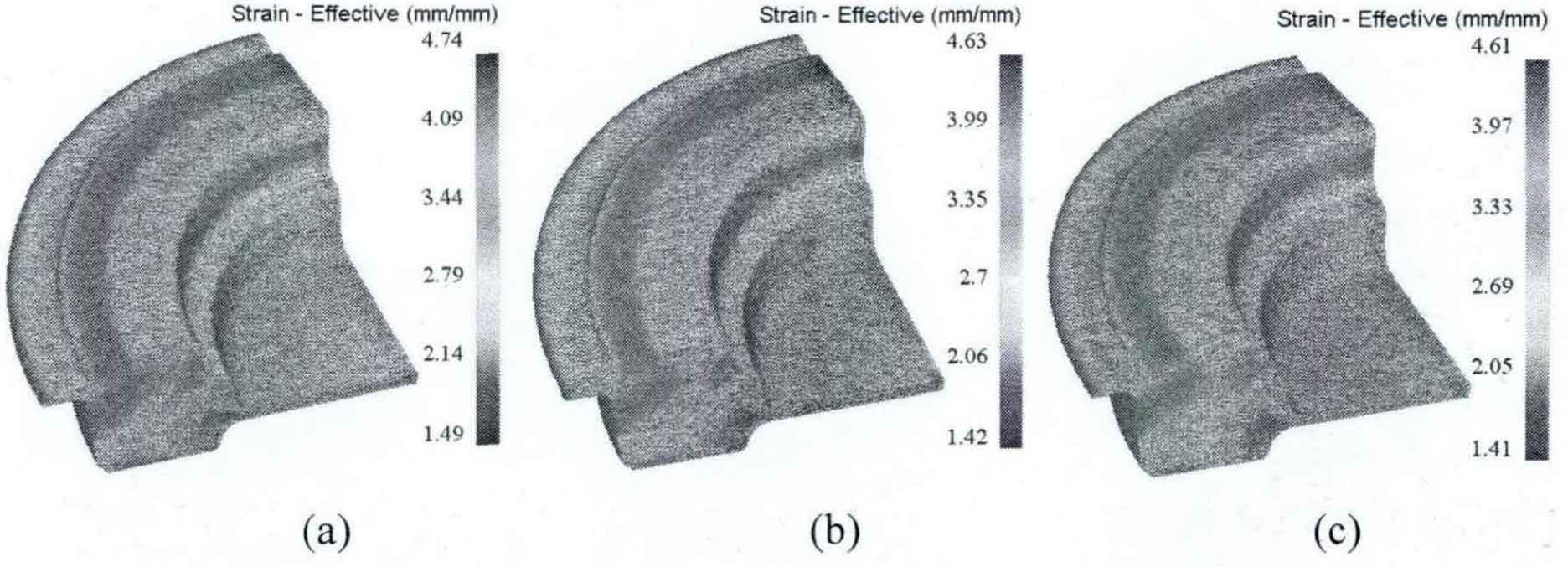

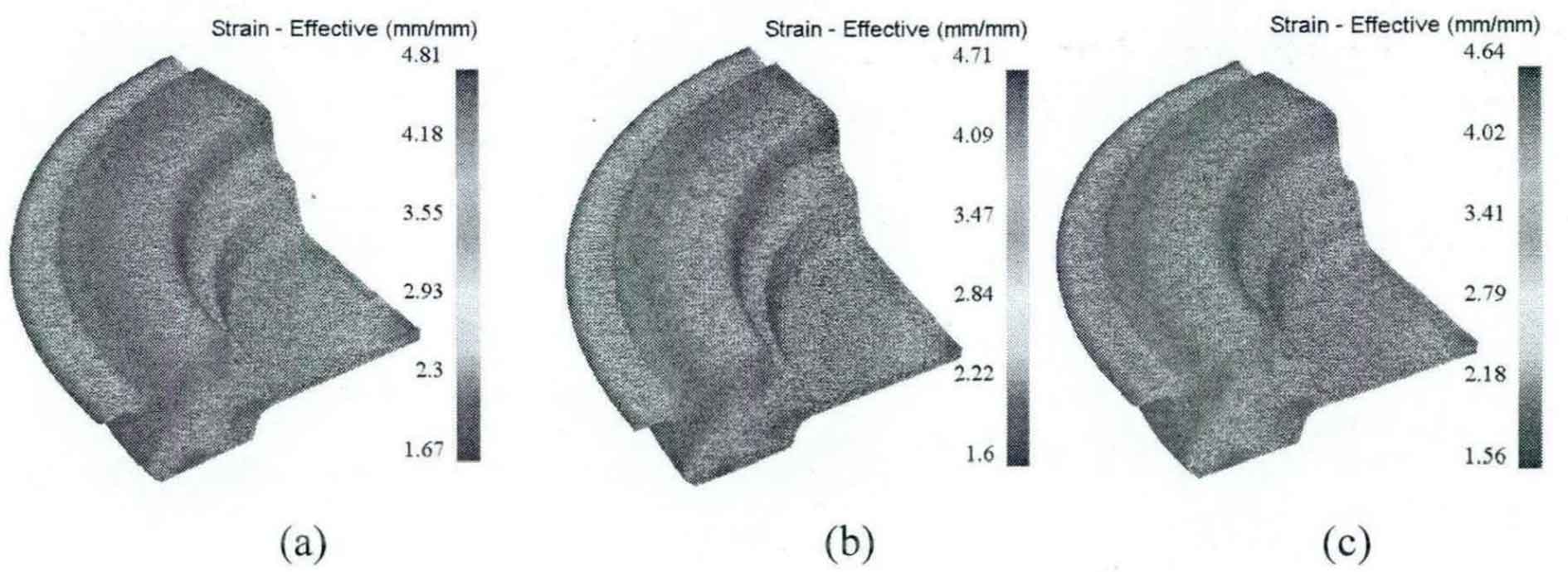

When the friction coefficient is 0.3 and 0.7 respectively, the equivalent stress and strain distributions at different initial forging temperatures are shown in Figures 1, 2, 3 and 4.

The numerical simulation results are shown in the table.

| Scheme | 1 | 2 | 3 | 4 | 5 | 6 |

| Temperature(°C) | 1000 | 1000 | 1050 | 1050 | 1100 | 1100 |

| Friction coefficient | 0.3 | 0.7 | 0.3 | 0.7 | 0.3 | 0.7 |

| Equivalent stress(MPa) | 608 | 636 | 580 | 623 | 556 | 602 |

| Equivalent strain | 4.74 | 4.81 | 4.63 | 4.71 | 4.61 | 4.64 |

It can be seen from figures 1, 2, 3, 4 and table that when the friction coefficient is the same, in the range of 1000-1100 ° C, the higher the initial forging temperature is, the smaller the equivalent stress-strain value of the forging is. It shows that when the friction coefficient is the same, the higher the initial forging temperature is, the more conducive to forging forming. When the initial forging temperature is the same, the equivalent stress-strain value when the friction coefficient is 0.3 is smaller than that when the friction coefficient is 0.7, indicating that it is necessary to add lubricant in the forging process, which is more conducive to forging forming and prolong the service life of the die.