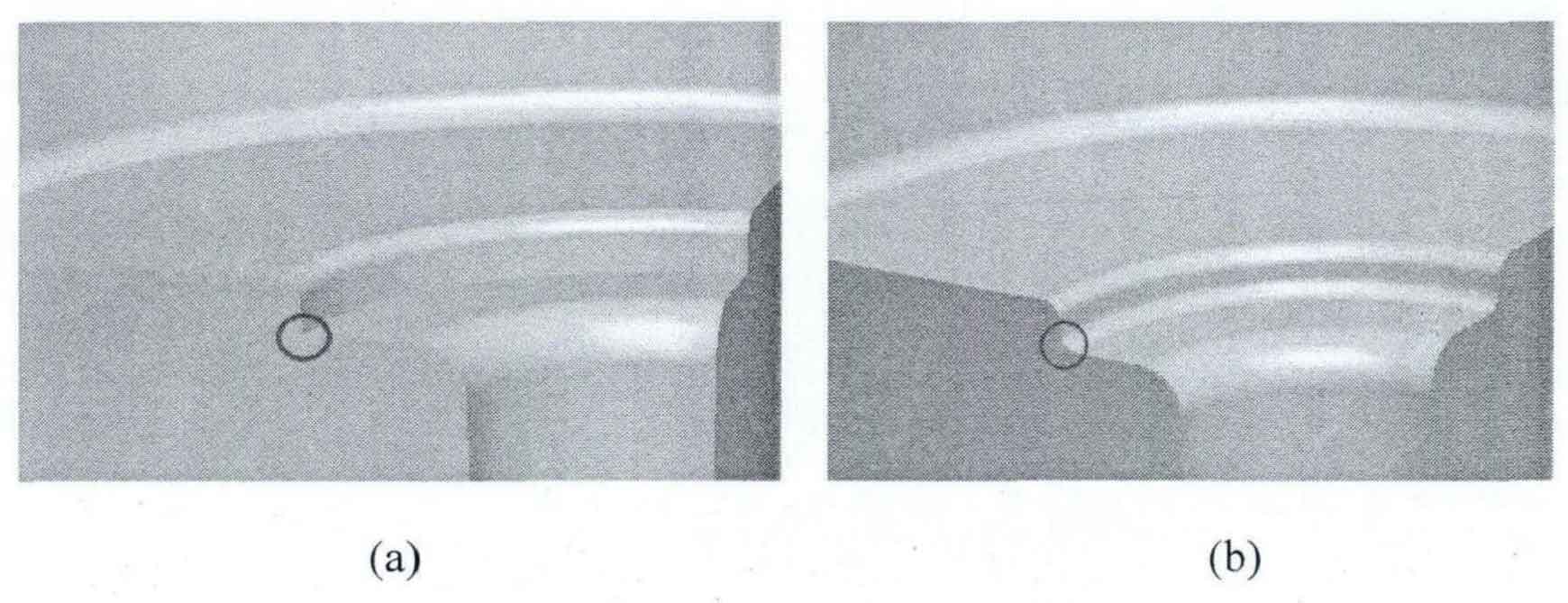

The equivalent stress, strain and temperature of spiral bevel gear forging during final forging are analyzed. It is found that the stress, strain and temperature at the step will increase sharply. This step is on the lower die. Now it is considered to pour a 2mm fillet at this step to improve the material flow. The three-dimensional partial view of the lower die before and after chamfering is shown in Figure 1.

1.Analysis of numerical simulation results after die improvement

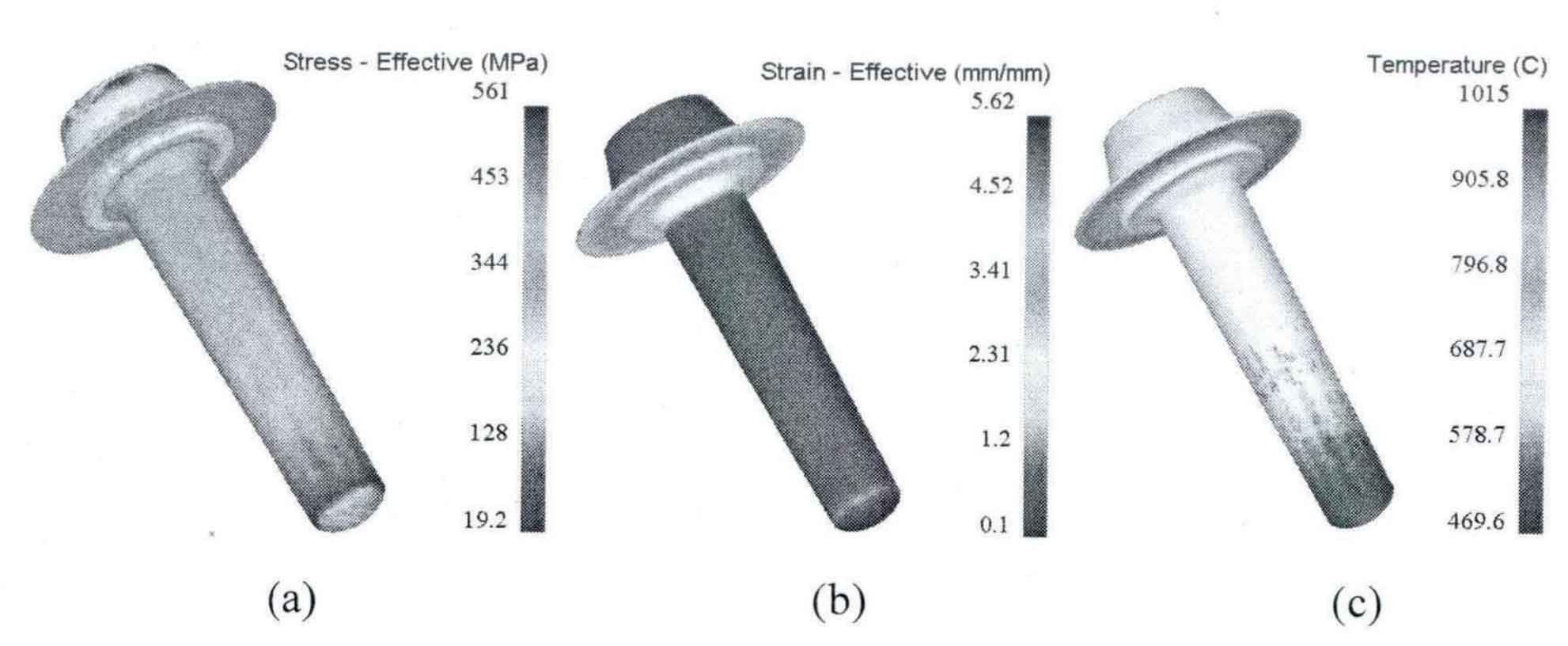

The distribution of equivalent stress, strain and temperature during final forging of spiral bevel gear die after improvement is shown in Figure 2. The maximum equivalent stress is 561mpa, which is 95mpa lower than that before improvement, and the maximum equivalent effect becomes 5.62, which is 0.18 lower than that before improvement; The maximum temperature is 1015 ° C, which is 586 ° C lower than that before improvement. These are because the material flow at the die step is improved after chamfering, the stress, strain and temperature at the forging step are significantly reduced, and there is no sudden increase in value.

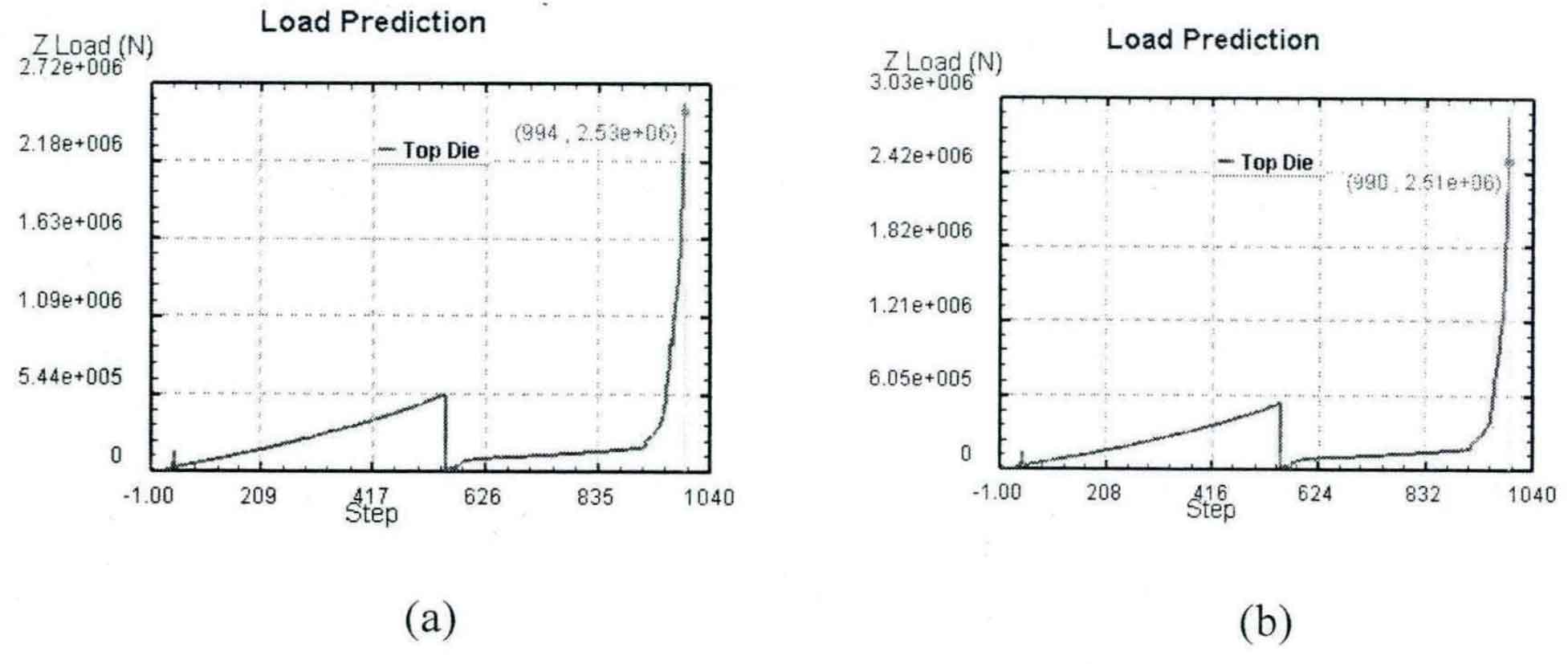

2.Load curve analysis of iterative steps before and after die improvement

The iterative step load curve of the general forming process before and after the improvement of the spiral bevel gear die is shown in Fig. 3. The forming load of final forging before improvement is 2.53t and after improvement is 2.51t, which is 0.02t lower than that before improvement.

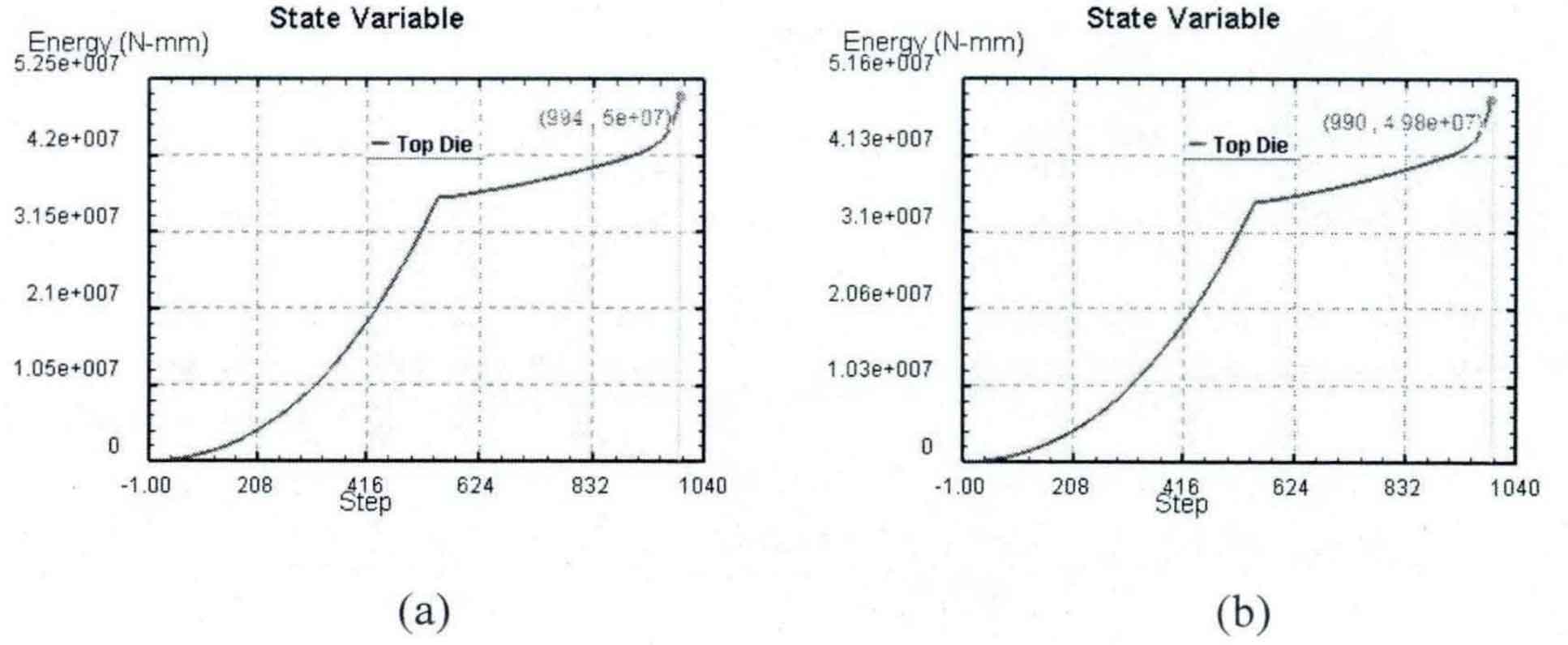

3.Analysis of energy consumption curve of iterative steps before and after die improvement

The iterative step energy consumption curve before and after the improvement of spiral bevel gear die is shown in Figure 4. The energy consumption of final forging before improvement is 50kJ, and that of final forging after improvement is 49.8kj, which is 0.2kj less than that of improvement.