Hypoid gear has a development history of more than 60 years and is widely used in the main reducer of drive axle of vehicles and construction machinery. The tooth surface of hypoid gear with spherical involute as tooth profile is spatial irregular surface, and the establishment of three-dimensional model is difficult, which is not conducive to the design of hypoid gear and the simulation analysis of meshing process. Therefore, it is necessary to carry out parametric design of hypoid gear.

According to the tooth direction, bevel gears can be divided into straight-line bevel gears and curved bevel gears. According to the mutual position relationship between axes, curved bevel gears include two kinds of bevel gears with intersecting and offset axes. In theory, the meshing state of curved bevel gears with intersecting axes can be simplified as pure rolling of cones with overlapping cone tops. When the axes intersect and mesh, the cone tops of the two gears coincide, and the bevel gear without relative sliding in the meshing process is called spiral bevel gear or spiral bevel gear. The axis offset bevel gear refers to that the axes of the two meshing gears are straight lines on different surfaces, and the distance between the straight lines on different surfaces is called the offset distance of hypoid gears. Due to the existence of offset distance, the cone tops of the two bevel gears do not coincide, and the original pitch cone surface changes from line contact to point contact, so it can not meet the transmission requirements. The pitch cone surface driven by the offset bevel gear can realize the transmission of rotational motion between the two vertical staggered axes by using the hyperboloid as the axis.

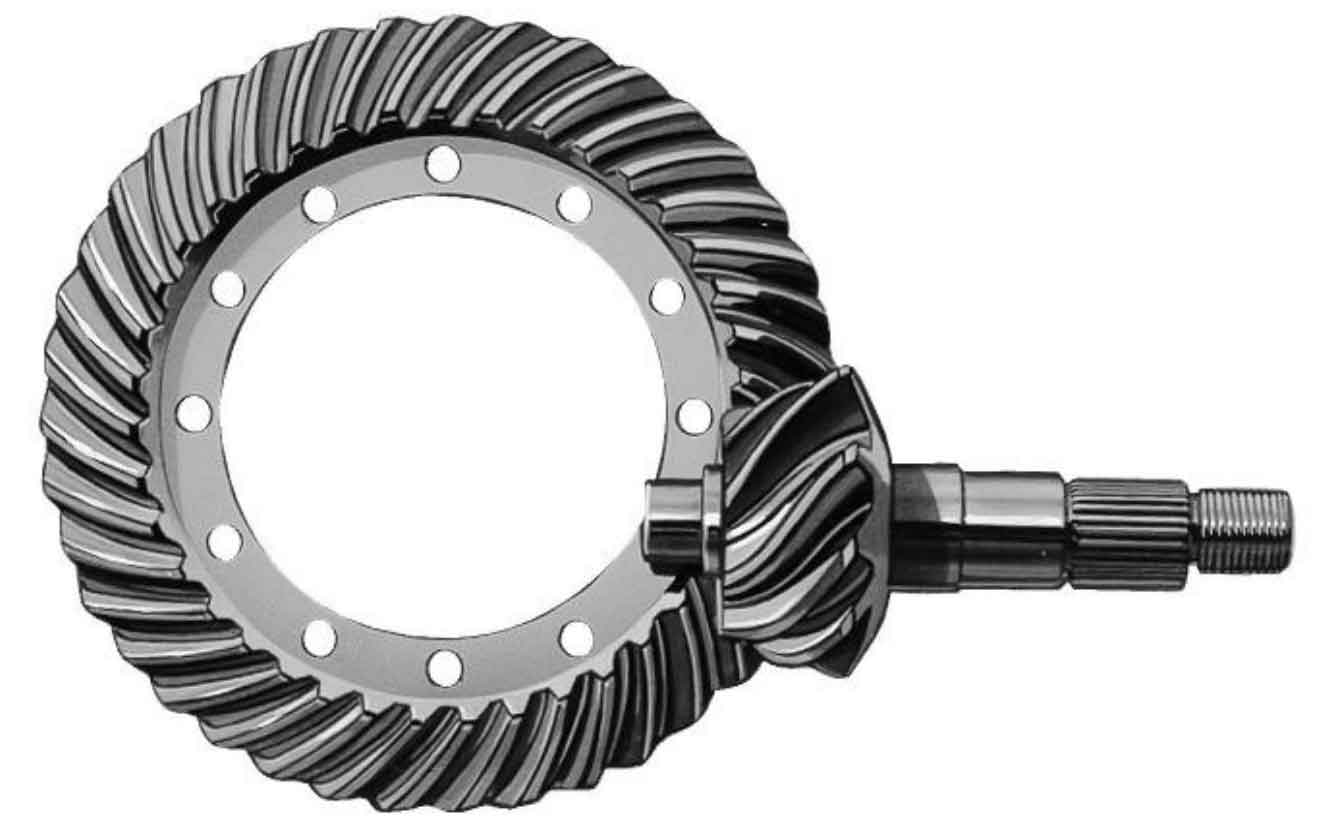

Because the gear with hyperboloid as pitch cone is difficult to process, in the actual gear generation process, the hyperboloid like spiral surface is used to replace the hyperboloid as pitch cone. Therefore, this kind of bevel gear with axis offset is called hypoid gear, as shown in the figure, it is hypoid gear pair. Hypoid gear is the most typical and representative kind of spiral bevel gear in gear transmission. If the offset distance of hypoid gear is zero, it is an ordinary spiral bevel gear; If the curvature of the tooth line in the tooth length direction is zero, that is, the tooth line is a straight line, it is transformed into helical bevel gear; If the axes of the two gears are parallel, they can be further transformed into cylindrical helical gears.