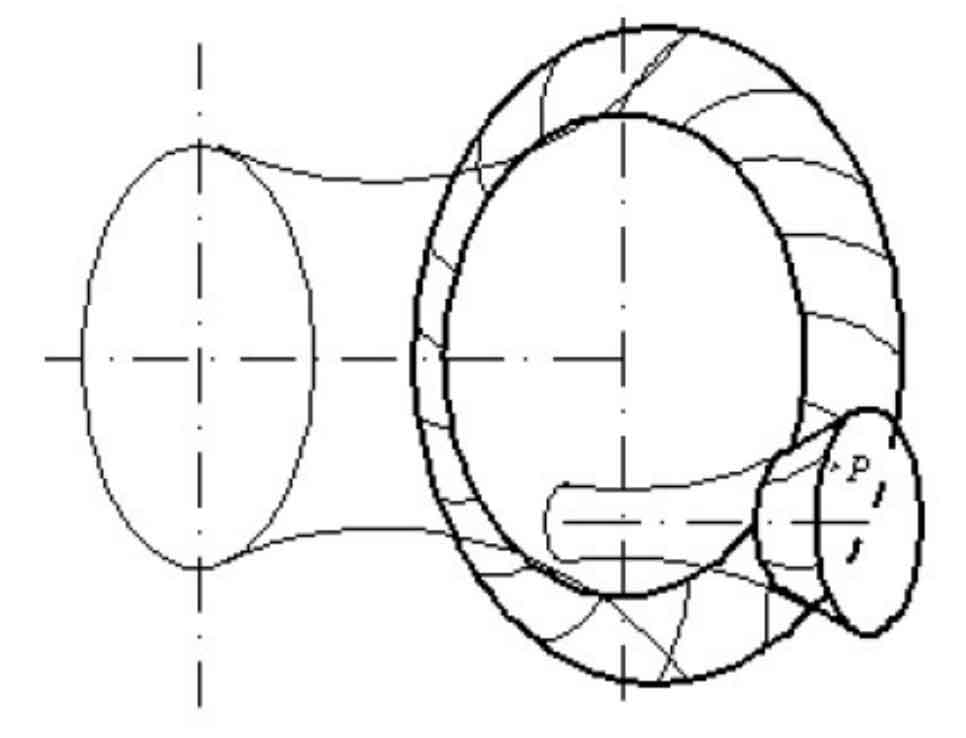

Hypoid gear pair is a transmission device used to transfer the motion and load between spatial staggered axes. According to the meshing theory, the relative motion between gear pairs is helical motion, and its pitch cone surface is a pair of single leaf hyperboloids formed by the rotation of helical axis around each gear axis. As shown in Figure 1, the pitch cone surface of two gears when the gear pair is meshed. Considering that the meshing range of the gear pair designed by the hypoid gear pair is far less than the length of the single leaf hyperboloid, one section of the single leaf hyperboloid can be intercepted as the pitch surface, and a similar conical surface can be used to replace the surface, so the pitch cone is a quasi double surface.

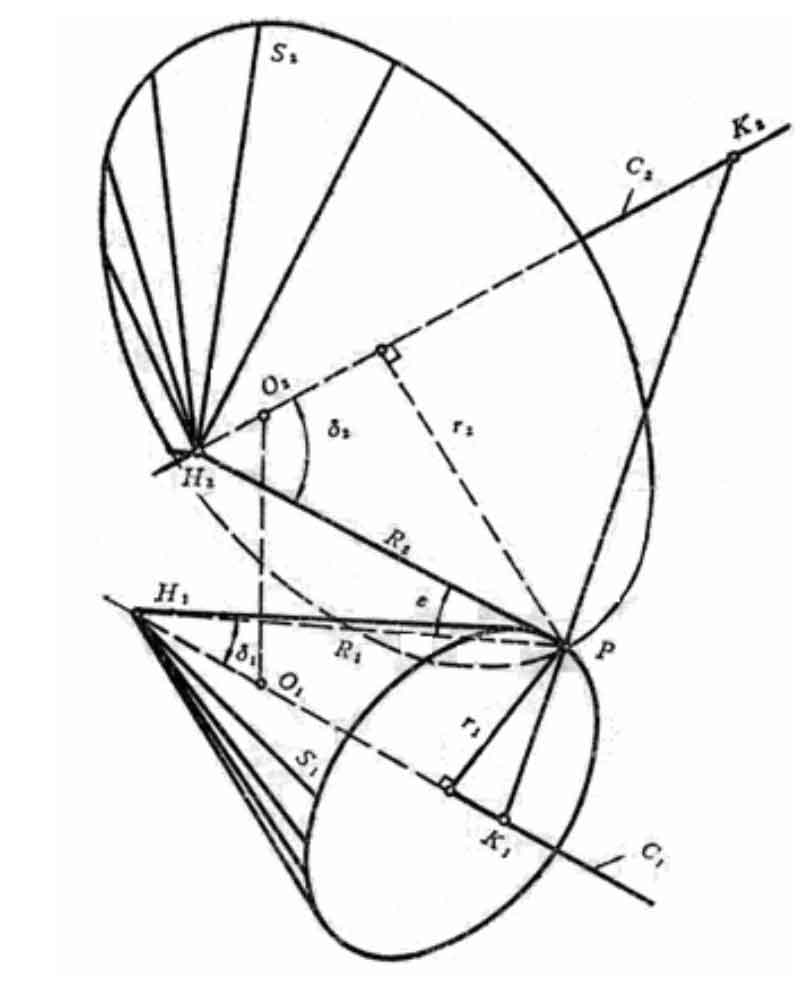

In the design of hypoid gear, the main task is to determine the two pitch cones of hypoid gear. As shown in Figure 2, the axis is a hypoid gear pair perpendicular to a straight line of different planes, and the straight lines o2k2 and o1k1 are the axes of large gear and pinion respectively. The common perpendicular O1O2 between the two axes is the shortest distance between straight lines on different planes, which is called the offset distance of hypoid gear, expressed by E.

The relative motion of hypoid gear transmission is spiral motion. The bevel gear transmission with intersecting axes can be regarded as a pair of line contact cones for relatively pure rolling. For the bevel gear pair with staggered axes, that is, hypoid bevel gear pair, because the pinion has an offset distance, the cone tops of large and small bevel gears do not coincide, and the two cones can only be in point contact, so it can not meet the application requirements of mechanical transmission. Only by using the “bell mouth” part of the hyperboloid as the pitch of the hyperboloid gear can the transmission of rotational motion between two vertical staggered axes be realized. Because the mathematical theory of single leaf hyperboloid is complex, which is not conducive to the study of meshing theory, two tangent conical surfaces similar to hyperboloid are used to replace hyperboloid, which is called pitch cone of hypoid gear pair. The common tangent plane between the pitch cones is called the pitch plane of the hypoid gear pair, and the tangent point of the pitch cone is defined as the node of the hypoid gear pair, and the midpoint P in Figure 2 is the node of the gear pair.

Point P is the contact position of the main and driven bevel gears at the midpoint of the tooth width. The vertical distance between point P and the two axes is R1 and R2, which is the indexing circle radius of the hyperbolic bevel gear at the midpoint of the tooth width. A unique straight line passes through the node P and intersects with the two gear axes D1 and D2. At the point passing through P, there is a unique plane perpendicular to the straight line, which intersects with the two gear axes O1 and O2 respectively. Two rolling hyperboloids can be obtained by rotating a straight line on the plane o1po2 around the axes of the two gears through point P. because the gear processing with hyperboloid as pitch cone is very difficult, we use a pair of approximate conical surfaces to replace the hyperboloid. These two conical surfaces are the conical surfaces obtained by rotating the straight line o1p and the straight line o2p around the axes of the two gears respectively. The two conical surfaces are tangent only at point P. It can be seen from the above that the position of node P is the key to determine the pitch cone of hypoid gear pair.