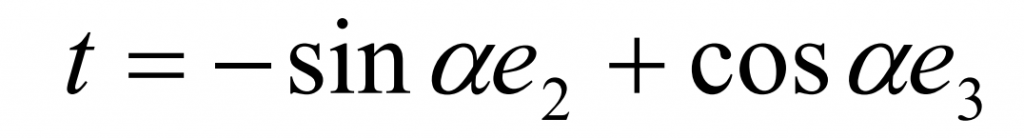

In the meshing transmission process of hypoid gear pair, the relative speed of the two gear tooth surfaces at node P coincides with the tooth line direction. Let the unit vector V = – E1 in the relative speed direction, and the direction perpendicular to V in the tangent plane at node P on the tooth surface is called the tooth height direction. Let the unit vector in the tooth height direction be t, then t = n x V, so,

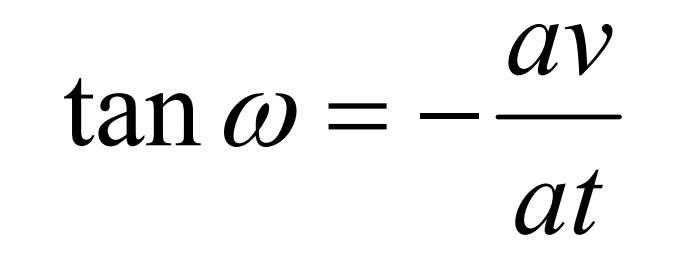

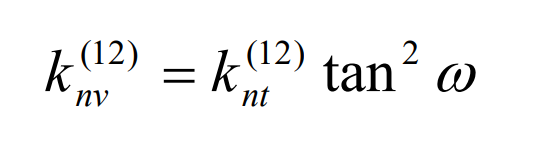

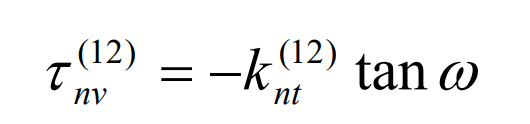

Let the normal curvature of the tooth surface of the big gear in the direction of tooth length and tooth height at node p be K (12) NV and K (12) nt respectively, and the short-range torsion along the direction of tooth length be τ (12) NV, then the included angle between the contact line of hypoid gear pair at node P and the tooth length direction can be obtained from the following gear meshing principle formula:

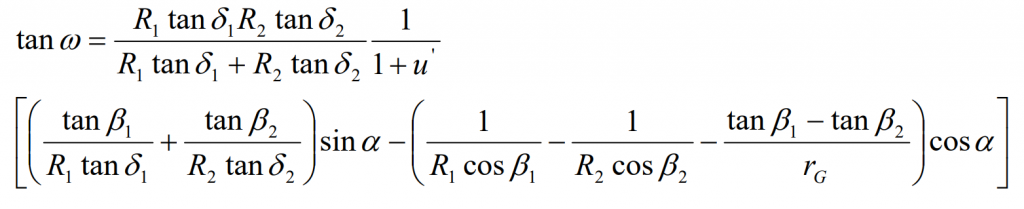

Where,

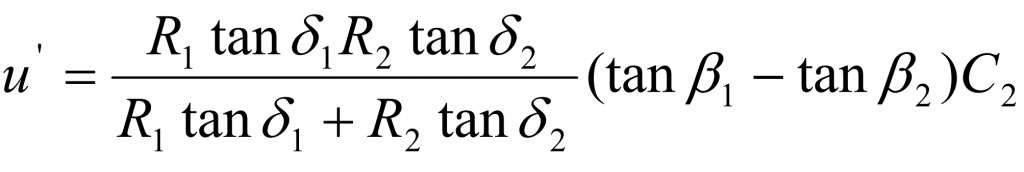

Let the curvature radius of the tooth line of the gear tooth surface at node p be gr, and set:

Based on the above formula:

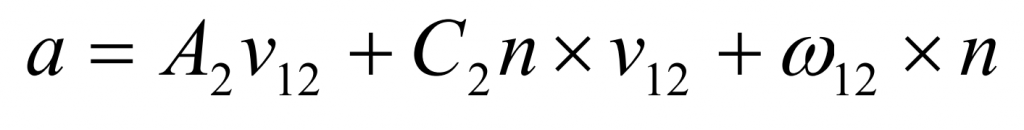

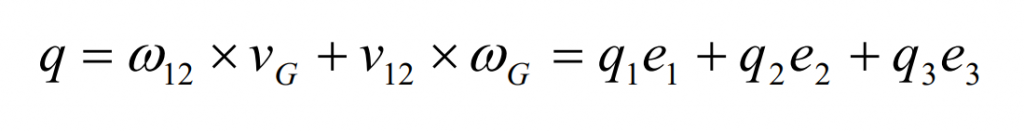

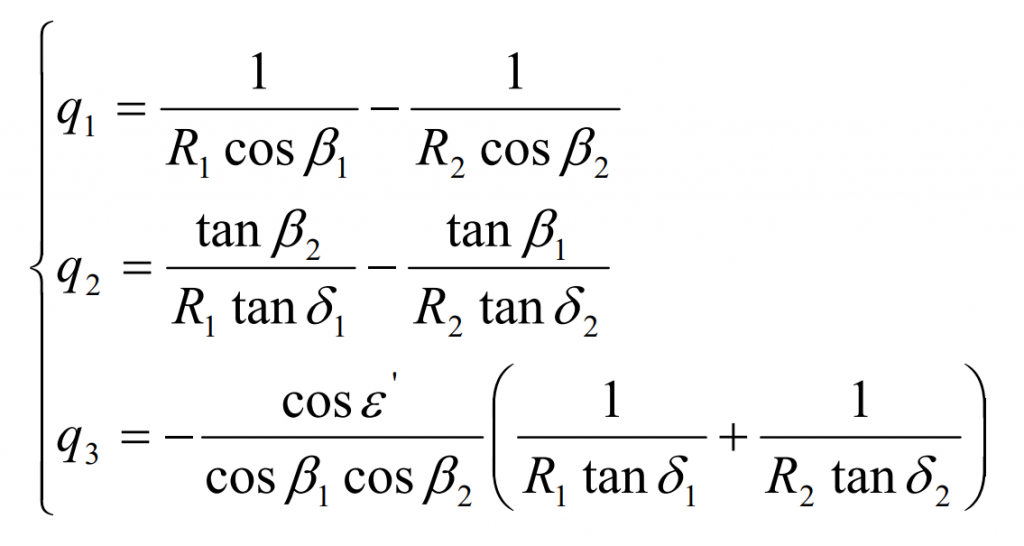

According to the meshing principle formula of hypoid gear:

Substitute the obtained variables into the above formula to obtain:

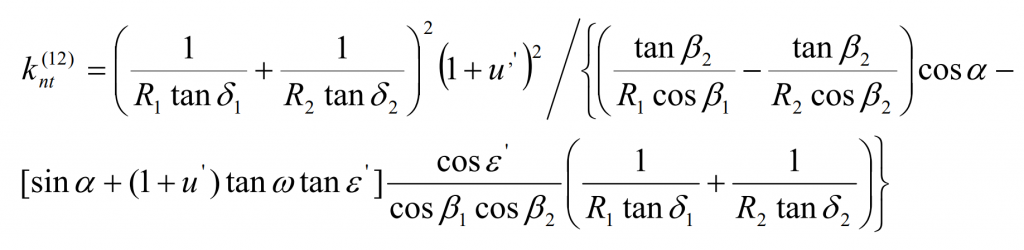

It can be concluded that the induced normal curvature of the spoke along the tooth height direction at node P is:

At node P, the induced normal curvature of hypoid gear pair along the tooth length direction is:

The induced short-range torsion along the tooth length direction at the node is:

K (12) NV and K (12) nt are negative for the convex surface of large gear and the concave surface of small wheel, and positive for the concave surface of large gear and the convex surface of small wheel, τ (12) NV is positive.