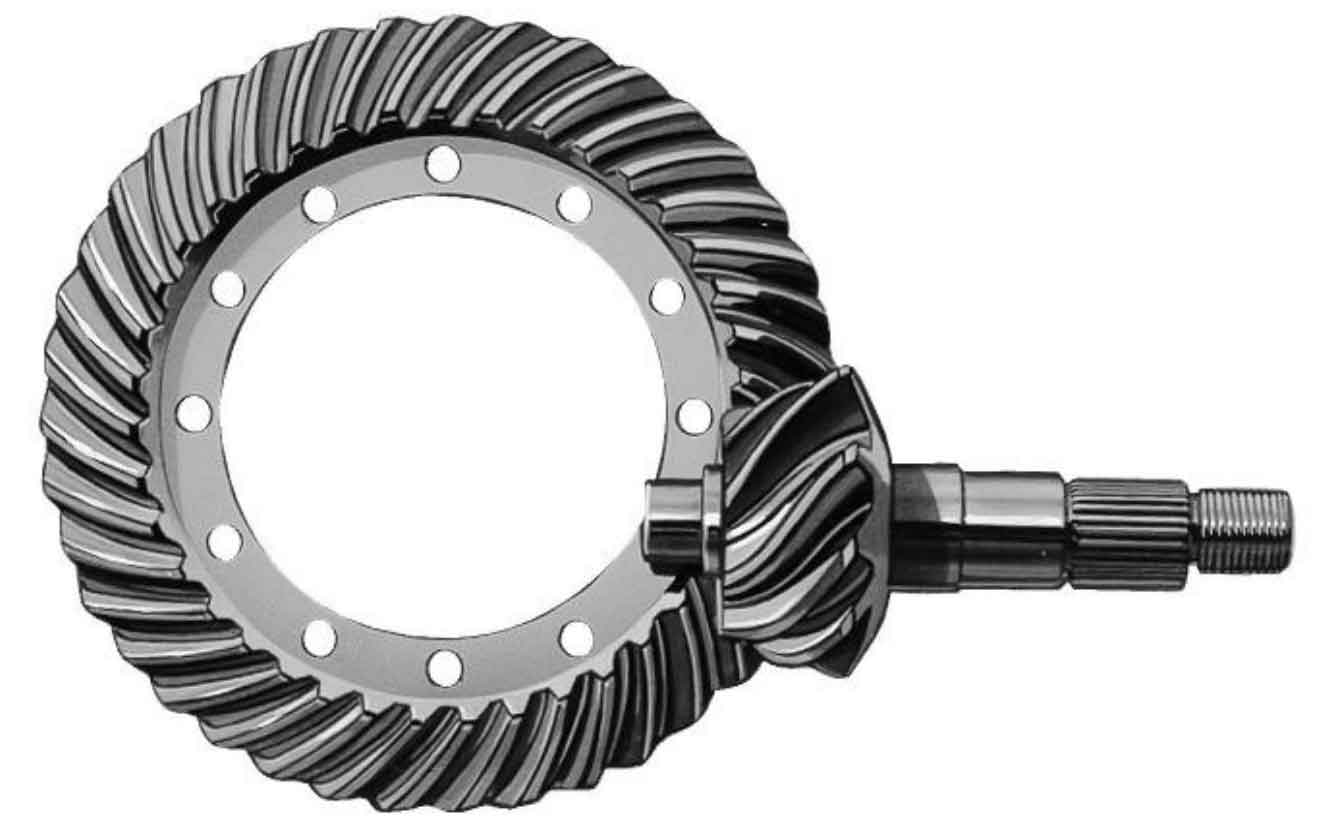

Hypoid gear pair is a special kind of curved bevel gear transmission used to transfer the motion and load between two staggered axes. Because the axis of the driving and driven bevel gear of meshing transmission is a spatial straight line with different planes, that is, there is an offset between the pinion axis and the big gear axis, and the distance between the straight lines with different planes of the two axes is the offset distance.

The existence of offset distance makes the spatial layout of hypoid gear pair more flexible. Due to the non coincidence of the conical tops of the two meshing gears, the helix angle of the pinion is increased, which increases the coincidence degree of hypoid gear pair. Therefore, the meshing process of hyperbolic gear transmission avoids the load impact caused by the sudden contact of each pair of teeth on its full length during the meshing of ordinary hypoid gear, and the meshing transmission is more stable than that of ordinary hypoid gear pair, The noise is also low.

Compared with the spiral bevel gear intersecting the axis, the hypoid gear pinion has a larger helix angle. When the number of teeth and normal modulus of the large gear are the same, the shaft diameter of the pinion is increased, so as to improve the bearing capacity, meshing stiffness and service life of the hypoid gear. The offset of the axis makes the hypoid gear pair slide relatively along the tooth length direction in the meshing transmission process, which accelerates the fatigue failure of the hypoid gear. Therefore, the hypoid gear pair transmission requires good lubrication conditions. In the process of machining, the relative sliding between hypoid gears makes the teeth easy to form, which is conducive to machining better tooth surfaces.