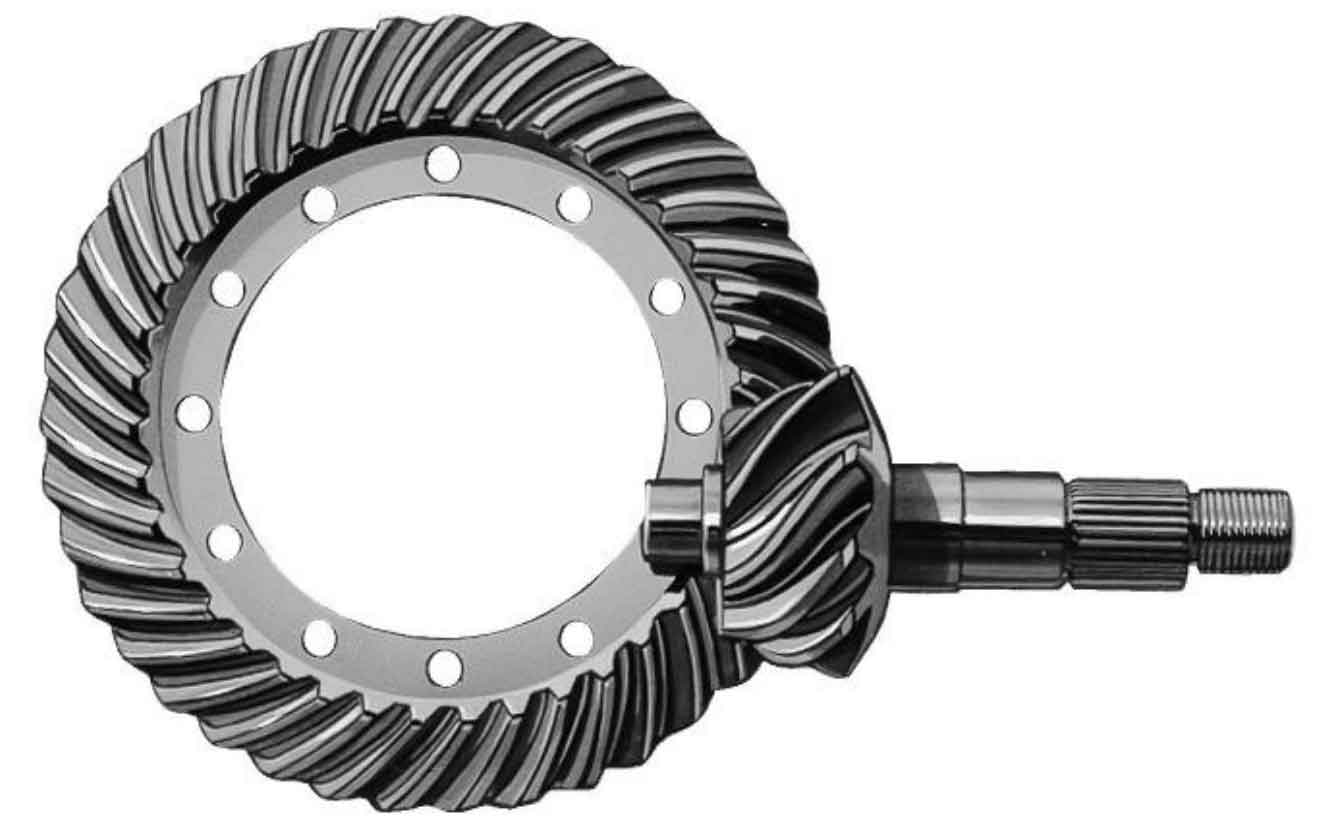

The meshing principle of hypoid gear pair is a point meshing theory based on the “local conjugate principle”. Because it takes the complex spherical involute as its theoretical tooth profile, and the tooth surfaces of large and small gears are irregular three-dimensional space surfaces, the establishment of three-dimensional model is more difficult. Seeking a relatively accurate and efficient three-dimensional model building method is of great significance for the in-depth study of hypoid gears. The three-dimensional modeling of hypoid gear mainly includes the following two methods:

1、 According to the parameters of multiple points on the tooth surface, the tooth surface of hypoid gear is fitted. This method is based on the local conjugate theory and the principle of differential geometry. The coordinate parameters of discrete points on the tooth surface are obtained by coordinate lattice transformation and matrix operation, and the tooth surface is fitted to obtain the three-dimensional model. This method requires profound knowledge of spatial meshing principle and a large number of coordinate matrix statistical calculation, which is difficult to master;

2、 The three-dimensional model is established by using the three-dimensional solid modeling software.

Using 3D software Pro / E2 The three-dimensional model of hypoid gear is established, which is the basis of parametric system.