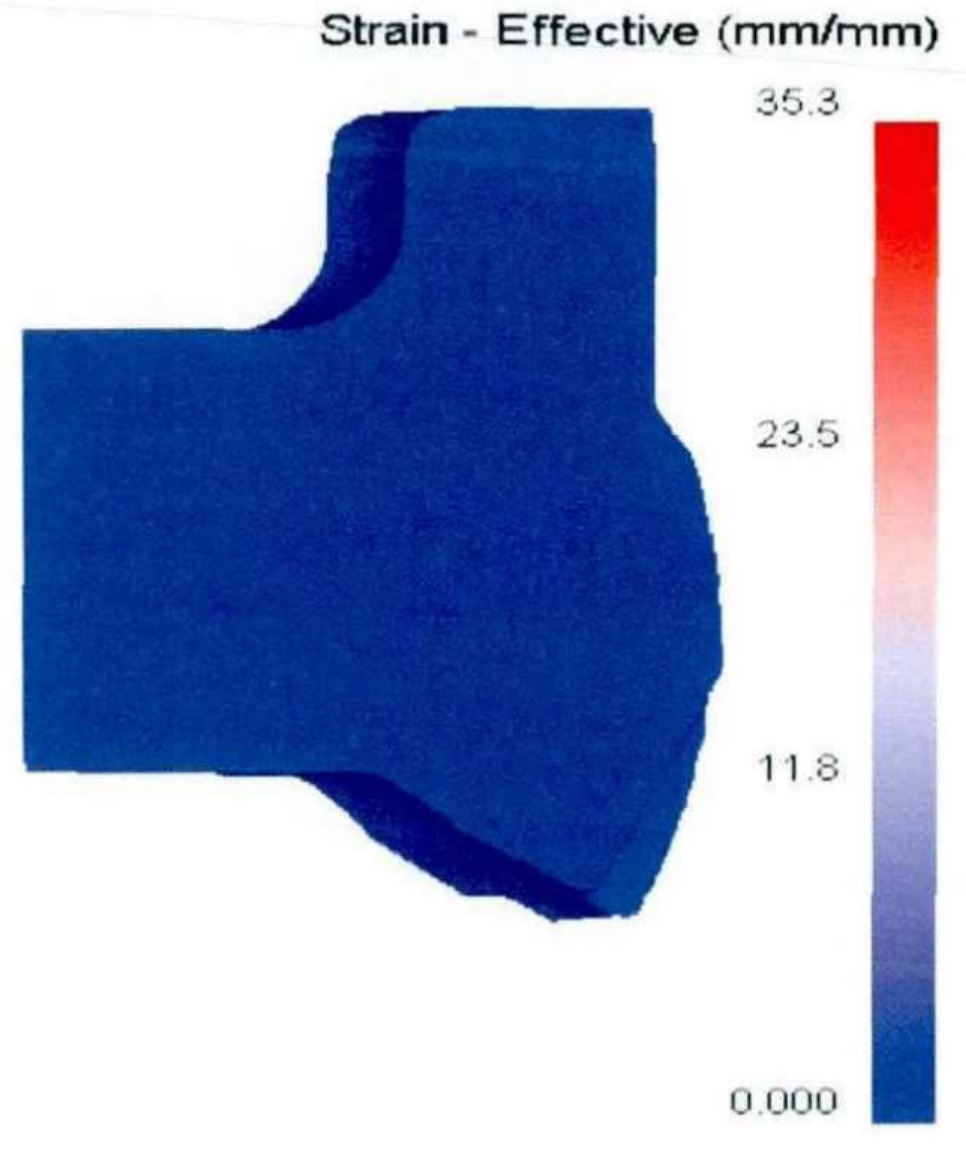

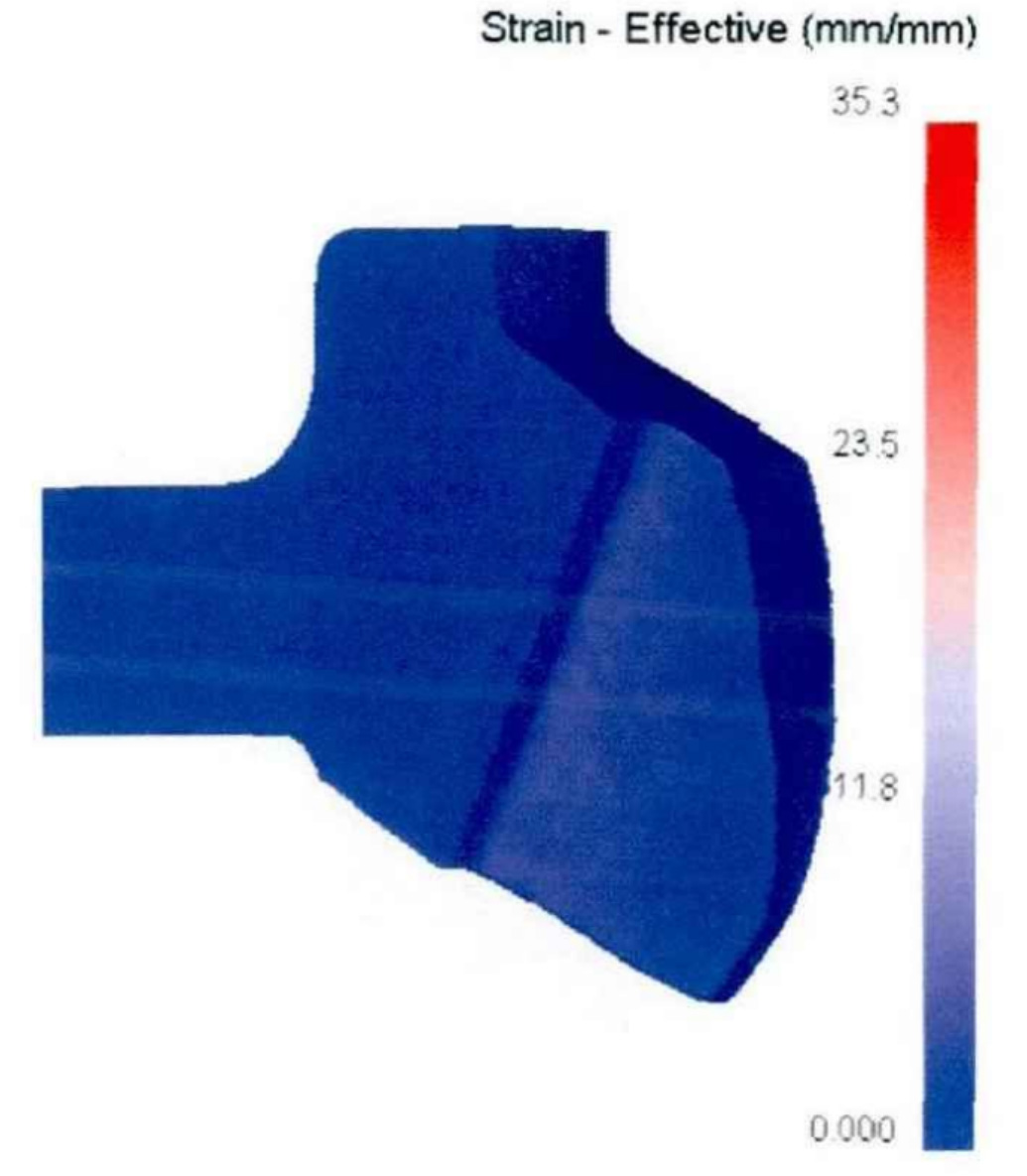

Strain is a physical quantity that represents the magnitude of deformation, the accumulation process of plastic deformation that has occurred and the development process of plastic deformation. Figure 1, figure 2 and figure 3 show the strain distribution of the spur bevel gear scheme at the end of the first stage, the second stage and the third stage respectively. At the initial stage of deformation, the surface of the spur bevel gear blank in contact with the upper and lower punch first begins to produce plastic deformation, and the strain is mainly concentrated in the contact area between the spur bevel gear workpiece and the punch fillet, which has the largest deformation. In the second stage, the outer surface of the lower end of the spur bevel gear workpiece in contact with the tooth root of the small end die begins to produce plastic deformation, and the strain decreases from the fillet of the tooth root to both ends. In this stage, the strain at the tooth root of the small end is the largest.

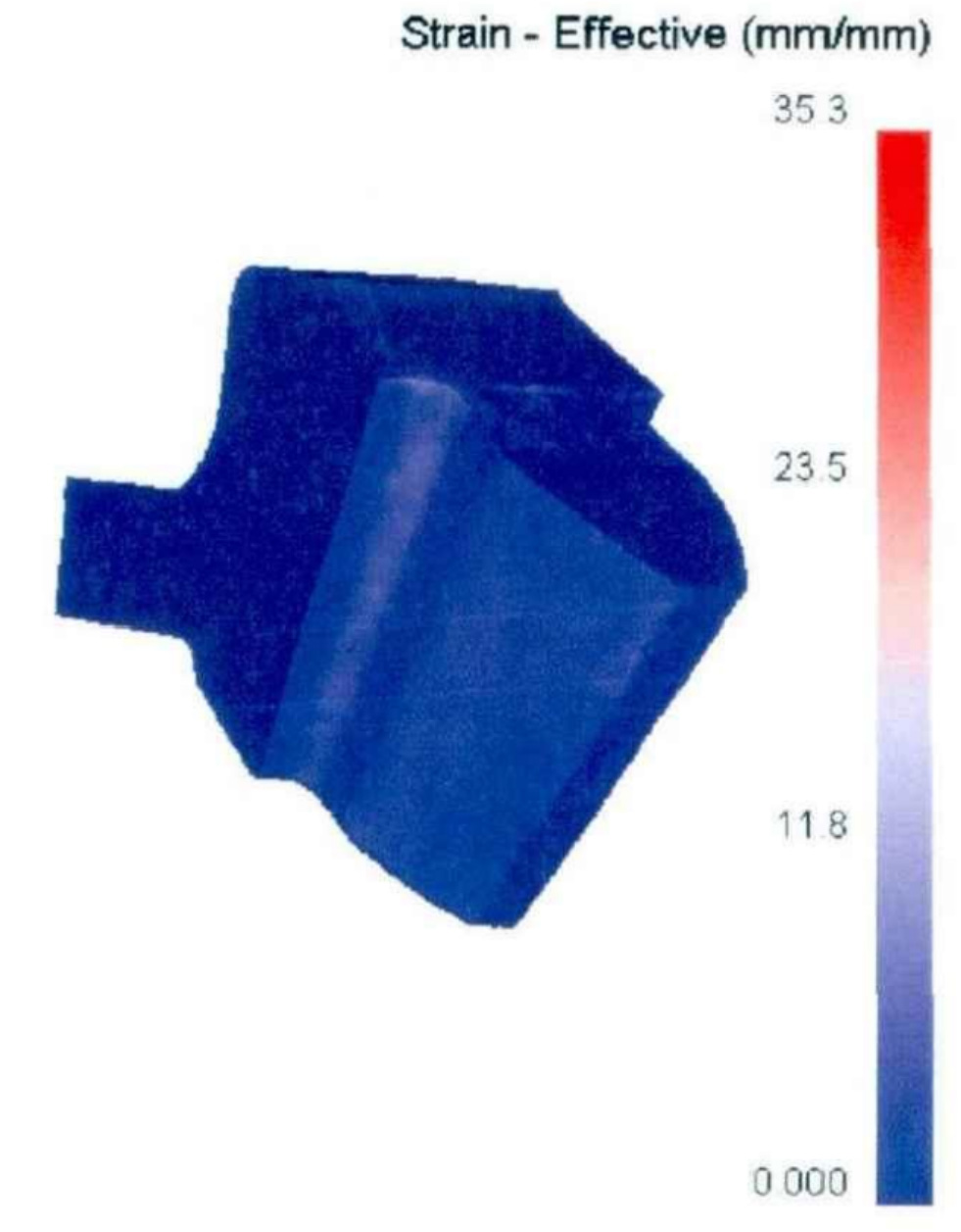

This is because in the second stage, the metal at the tooth root of the small end tooth die not only compresses and deforms along the axial direction, but also fills the tooth cavity along the radial direction. With the filling process of the tooth cavity, the maximum strain region begins to move to the root of the big end die. This shows that the metal deformation is mainly concentrated in the root area of the large end tooth after the filling of the small end tooth top, and the metal does the transverse filling movement of the tooth cavity. At the late filling stage of the tooth cavity of the spur bevel gear, the large end tooth crest produces large strain, and the metal deformation is still mainly concentrated in the large end tooth root area.