Gear is an important part widely used in automobile, machinery, aerospace and other industries. Gears processed by precision die forging process can be directly used due to good surface quality and high dimensional accuracy without subsequent cutting, which greatly improves the material utilization and production efficiency and reduces the production cost. At the same time, the precision forging process can improve the internal structure of the material and make the gear obtain better performance. The closed precision forging process of spur bevel gear is simulated and analyzed, the influence law of its process parameters on the forming quality is studied, the elastic deformation of the die and the elastic recovery deformation of the forging are analyzed, and the compensation design method of the die tooth profile cavity size is established to realize the accurate forming of spur bevel gear.

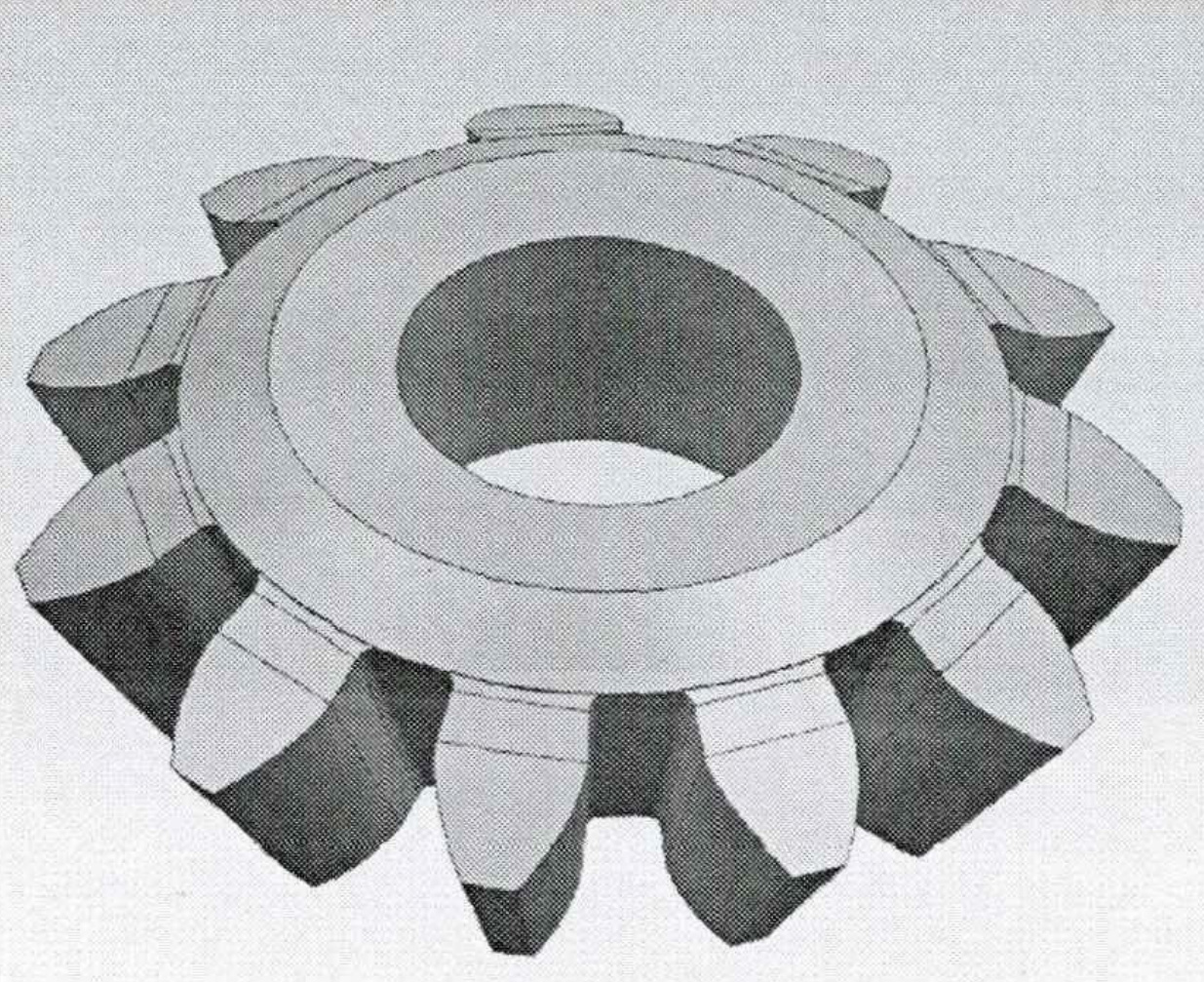

- A common differential planetary gear is selected as the research object, and the technological process and related technological parameters of closed precision die forging of spur bevel gear are formulated. The three-dimensional design of the part is carried out by software. The forging drawing and die are designed according to the selected closed forming process requirements and forging drawing design criteria.

- Using DEFORM-3D software to carry out numerical simulation of forging process, using orthogonal test method to design a four factor three-level test scheme, optimize the design for the factors affecting the forming of spur bevel gear, and visually analyze the orthogonal test results.

- Select the process parameters of the orthogonal test group as the optimal combination of process parameters and conduct finite element simulation analysis. The velocity field, strain, stress, forming load and filling property of the metal under this scheme are analyzed.

- Obtain the elastic deformation of the gear lower die after forging and the spring back of the forging after die drawing, use MATLAB software, use the reverse superposition method to superimpose to the surface of the standard die cavity, correct the die cavity, and obtain the node information of the die cavity that can accurately form the gear.