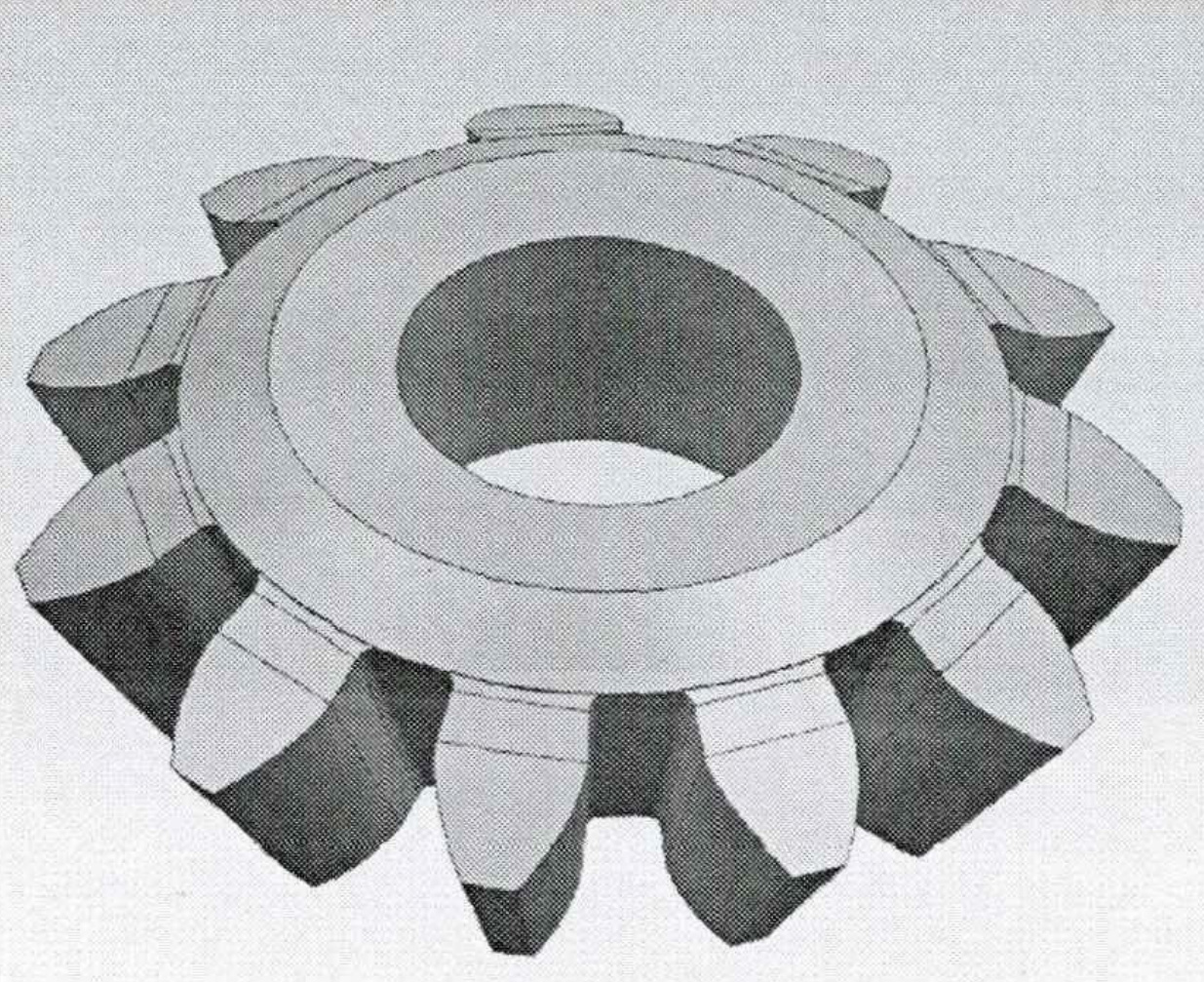

For precision die forging, it is very important to remove the oxide skin on the bevel gear blank and forging surface. The following describes several common methods to remove the oxide skin on the surface of bevel gear blanks and forgings. According to the use requirements of bevel gears and the needs of precision die forging process, the appropriate oxide skin removal method is selected for planetary gears and half shaft gears.

(1) Remove the oxide skin on the surface of bevel gear blank

The common methods to remove the oxide scale of blank include acid pickling, dry drum cleaning, turning and centerless grinding. Both dry drum cleaning and acid pickling can only remove the oxide skin, but can not remove the decarburized layer on the surface. If it is necessary to remove the oxide skin and decarburization layer at the same time, the surface of the blank shall be stripped by turning or centerless grinding. However, the cost of turning and grinding is high. This method can only be used when less and no oxidation heating can ensure the decarburization depth requirements of bevel gear forgings and the main parts of bevel gear forgings do not need to be cut.

(2) Remove the oxide skin on the surface of bevel gear forgings

The methods to remove the oxide scale of bevel gear forgings generally include acid pickling, dry drum cleaning, wet drum cleaning, sand blasting or shot blasting, etc. Dry and wet drum cleaning will cause deformation of bevel gear forgings and blunt the sharp corners of bevel gear forgings. In order to avoid deformation of bevel gear forgings during cleaning, sand blasting or shot blasting can be used. This method will cause less damage to bevel gear forgings than drum cleaning, will not cause warpage and deformation of bevel gear forgings, and can also improve the surface hardness of bevel gear forgings. The important bevel gear forgings shall be cleaned by acid pickling. The advantage of acid pickling is that it will not cause the deformation of bevel gear forgings and can expose the surface cracks of bevel gear forgings.

(3) Removal of oxide scale in each process of precision forging bevel gear

The blank of forged bevel gear is a cylinder cut by high-speed band saw. Because the gear tooth surface after precision forging is directly used without cutting, the requirements for the oxide skin thickness and decarburization layer on its surface are extremely strict. Before heating the blank with little or no oxidation, the oxide skin and decarburization layer on the surface of the blank shall be removed. The defect layer on the surface of the blank shall be removed by turning the excircle with a cutting allowance of 1.0-1.5mm. The bevel gear is precision die forged by “one fire two forging” process. The operation of removing the oxide skin on the surface of the pre forging is carried out in the hot state. At this time, the oxide skin on the surface of the high-temperature forging needs to be brushed with a steel wire brush. After the final forging, the surface oxide scale shall be removed by sand blasting after cold trimming.