The tooth profile of precision forging die cavity bevel gear is based on the tooth profile of hot forging bevel gear, considering the elastic deformation of blank and die and the cold shrinkage of die in the forging process. The working temperature of the die is not very high, and preheating is required before forging, so its shrinkage can be regarded as linear. The influence of elastic deformation on the tooth profile of bevel gear is also linear, so the tooth profile of die cavity can be obtained by the linear change of the tooth profile of hot forging bevel gear.

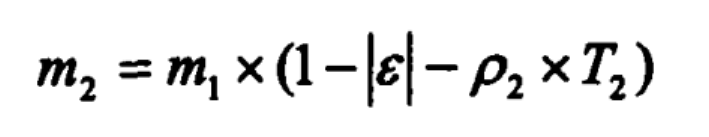

For linear expansion hot forgings, the bevel gear profile is an ideal involute, so the tooth profile parameters of the die cavity bevel gear can be obtained by modifying the module. The formula is as follows:

Where

M2 – tooth profile modulus of die cavity bevel gear;

M1 – tooth profile modulus of bevel gear of linear expansion hot forging;

ρ 2 – linear expansion coefficient of die material;

T2 – working temperature of die;

ε— The sum of the elastic recovery strain of the forging after being out of the die and the elastic strain of the die during forging.

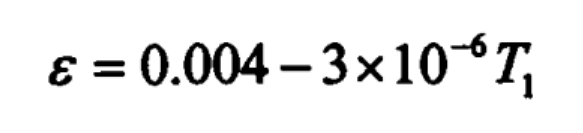

According to Hooke’s law and experiments, Tian Fu established the calculation ε Simple formula for:

Where T1 – forging temperature at the end of forging.