Straight bevel gears are formed by “one fire and two forging”. The tooth surface of the tooth die is subjected to the thermal impact of the high-temperature gear blank, and the temperature rises rapidly, up to 600 ° C. after the forging is out of the die, the water graphite is used for cooling and spray lubrication. The straight bevel gear tooth die needs to bear the cold and hot alternating load, and the working conditions are very poor. Therefore, when precision forging spur bevel gear, the tooth die is the earliest failure and the shortest service life. It is the key part of precision forging spur bevel gear.

In order to improve the strength and service life of the spur bevel gear die, in addition to considering the die material to improve the bearing capacity of the material itself, it is also necessary to start from the die structure design to effectively use the die material and ensure the bearing capacity of the die. Therefore, the tooth profile die of spur bevel gear is designed into a double-layer combined cylinder structure, the outer layer is a die sleeve, and the inner layer is a tooth profile cavity die. The interference fit between the inner and outer layers not only saves the die steel, but also improves the rigidity, strength and die life, and reduces the production cost.

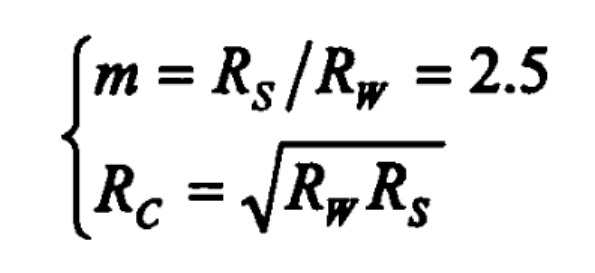

The radial dimension of the combined die is calculated according to the following formula:

Where

RW – workpiece radius, i.e. maximum internal radius of female die;

RS – outer radius of die sleeve;

RC – inner radius of die sleeve, i.e. outer radius of female die.

The tooth profile concave die of spur bevel gear is designed as a double-layer combined cylinder structure. Deformation will occur during heat treatment of the concave die and hot press fit between the concave die and the die sleeve. Therefore, generally, the die sleeve and concave module should be machined, heat treated, press fit and assembled respectively, and then the electrode gear is used to process the tooth profile cavity. In order to ensure the machining accuracy of the tooth profile cavity, it is necessary to select a high-precision gear planer to process the electrode gear. In order to reduce the surface roughness of the machined surface of the electrode gear and improve the dimensional accuracy of the cavity, it should be processed in three stages: rough, medium and fine. The discharge intensity is from strong to weak, and the discharge gap is from large to small.