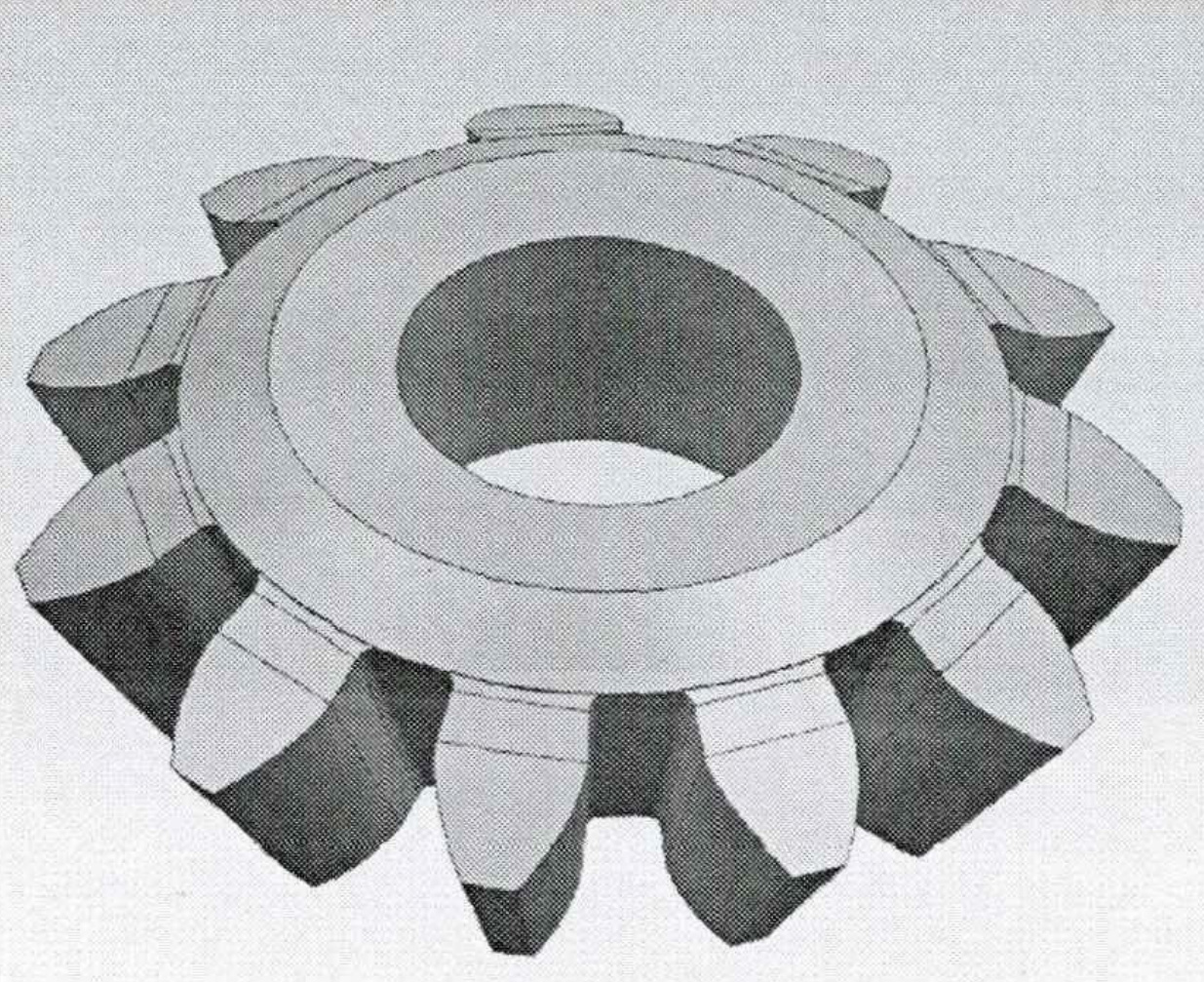

Spur bevel gears are widely used in the differentials of automobiles, tractors, motorcycles, tanks and other walking machinery. They have a wide range of applications, large demand and easy wear. Using traditional machining method to produce spur bevel gear has the advantages of slow speed, low efficiency and poor precision. Using precision die forging method to produce spur bevel gear has the advantages of high production efficiency, saving man hours, less material consumption, high product quality, low production cost and long service life. Its production and Application has very important economic significance and broad prospects.

At present, the process of “one fire two forging” to form large module spur bevel gears has been relatively mature. However, due to the large deformation of the teeth during precision forging of spur bevel gears, there are often problems such as insufficient filling of the tooth top, excessive forming load and premature failure of the tooth die. In addition, there are many factors that affect the tooth surface accuracy of spur bevel gears formed by “one fire two forging” process, which makes it difficult to design the tooth profile and ensure the tooth surface accuracy of spur bevel gears. Therefore, the “one fire two forging” process of two typical spur bevel gear planetary gears and half cycle gears is studied. The main conclusions are as follows:

(1) The involute tooth profile curve equation with the basic tooth profile parameters as independent variables is established. The tooth profile curve of spur bevel gears can be easily and accurately obtained by using the curve command in. The quantitative relationship between the basic tooth profile parameters of finished gears, forged gears, die cavities and electrode gears is derived, It can conveniently and effectively realize the design from the tooth profile of the finished gear to the tooth profile of the electrode. A new tooth profile design model of the non-linear expansion heat forging is proposed, and the tooth profile curve equation of the non-linear expansion heat forging is established, which makes the tooth profile design of the precision forging of spur bevel gear more accurate.

(2) The shape and size of preform, pre forging and forging of planetary gear and half shaft gear are designed, and on this basis, the forming force of forging planetary gear and half shaft gear is estimated. Finally, some key technologies of forming spur bevel gear by “one fire two forging” process are analyzed.

(3) DEFORM-3D is used to simulate the precision forging process of planetary gears with different preform sizes. The strain, stress, strain rate, velocity distribution and load stroke curve in the precision forging process of planetary gears under three schemes are analyzed. The optimal preform height diameter ratio is determined. The final forging process of planetary gears and half shaft gears is simulated. The simulation results show that the design of the shape and size of the preform is reasonable, The order of metal filling the tooth cavity is effectively improved. The metal first fills the tooth top, then from the tooth top to the tooth surface, and finally fills the tooth root. It can not only ensure full filling of the tooth profile and avoid insufficient filling of the tooth top of the forging, but also fill the tooth cavity in the form of upsetting, which can effectively reduce the forming load.

(4) According to the process design and numerical simulation results, two sets of die structures for pre forging and final forging of spur bevel gear formed by “one fire two forging” are designed. The die can ensure the accurate guidance of upper and lower dies and the smooth demoulding of forgings. The key points of tooth die design and processing are discussed. The selection of die materials and the ways to improve the service life of spur bevel gear die are briefly introduced.