Curve fitting has been carried out for the cutting areas of the left and right tooth surfaces of the large and small hypoid gears respectively, and new parameters have been generated on the Q surface. The machining motion equation of the left and right tooth surfaces of this hypoid gear will be derived. The conical spiral involute surface is formed when the base cone rolls around the center O of the base plane (i.e. the vertex of the base cone) on the tangent plane (q). Here, pure rolling means that there is no sliding between the base cone and the base plane, assuming that the angular velocity of the base plane in pure rolling is ω The self rotation angle velocity of the base cone itself is expressed by ω 1 means that the two angular velocities must satisfy the following formula, ω/ω 1= sin δ h. Of which δ H is the base cone angle. On the yk2250 CNC spiral bevel gear milling machine, the rotation of the base plane is realized by the revolution of the gear blank around the apex of the base cone.

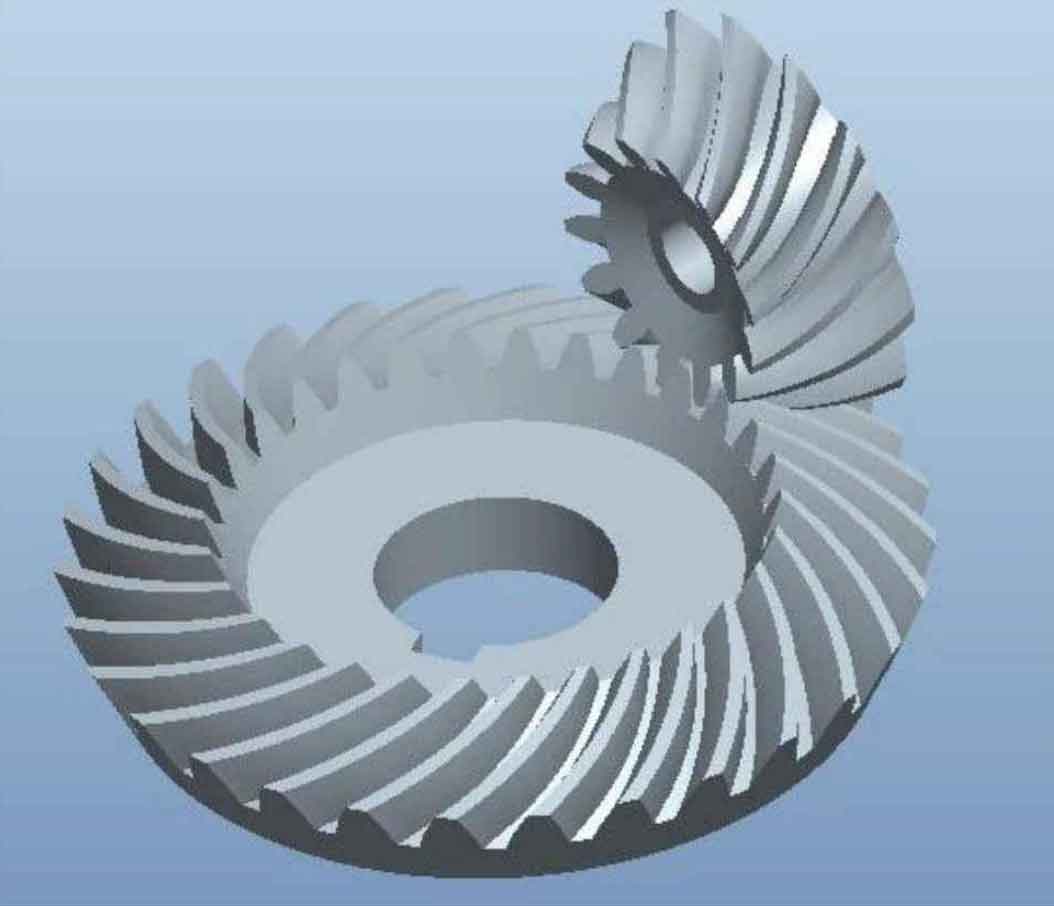

The production line of machining hypoid gear is a complex conical curve, but through the substitution of production line and error analysis, it can be seen that the straight production line can be used to machining hypoid gear. The generating line cutting edge used in this paper is formed by the high-speed rotation of disc milling cutter. A pair of Gleason hypoid gears used in the rear axle of an automobile are given, in which the rotation direction of the hypoid gear wheel is right rotation and the rotation direction of the hypoid gear pinion is left rotation.

Because of the different base cone angles of the left and right tooth surfaces of the hypoid gear, its cutting motion equations are also different. The cutting motion equations of the left and right tooth surfaces are derived; The gear blank is designed and the simulation model of the machine tool is established; According to the cutting motion equation and related hypoid gear parameters, the machining program is compiled, and the program is imported into the simulation model for simulation; In this chapter, the feasibility of manufacturing hypoid gears by the method of generating line gear cutting is verified by simulation experiments.