There are many methods for machining the left tooth surface. As long as the relationship between the base cone and the base plane is pure rolling, and the production line is cut along the boundary tangent, four machining methods are briefly introduced here.

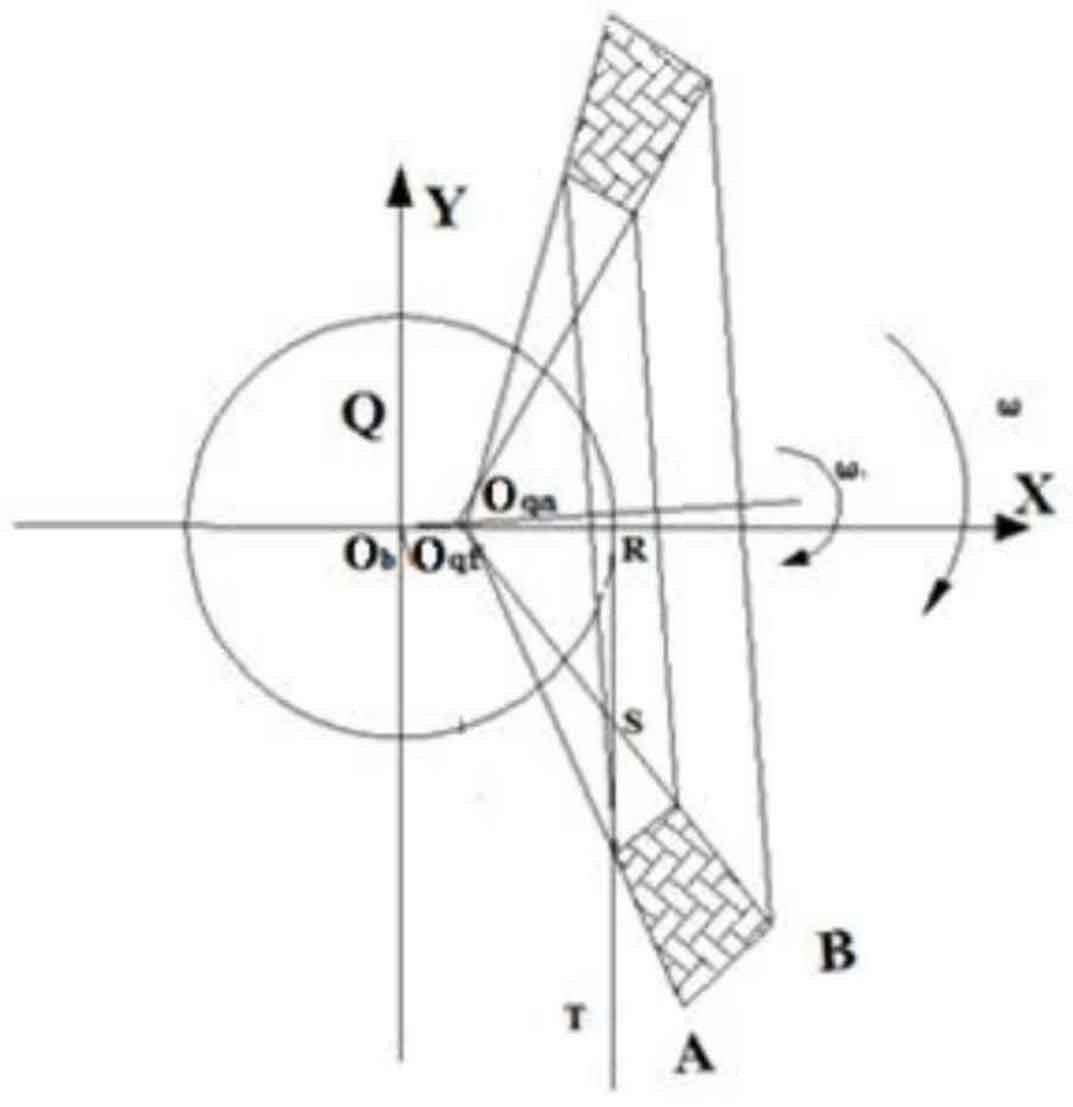

1) The tooth blank part of the left tooth surface of the hypoid gear wheel is placed in the fourth quadrant for machining. At this time, the outer edge of the milling cutter is used. In Figure 1, the gear blank rotates clockwise and rotates accordingly, and the milling cutter tangents from the small end of the hypoid gear to the big end of the gear, and from the top of the small end to the big end tooth root.

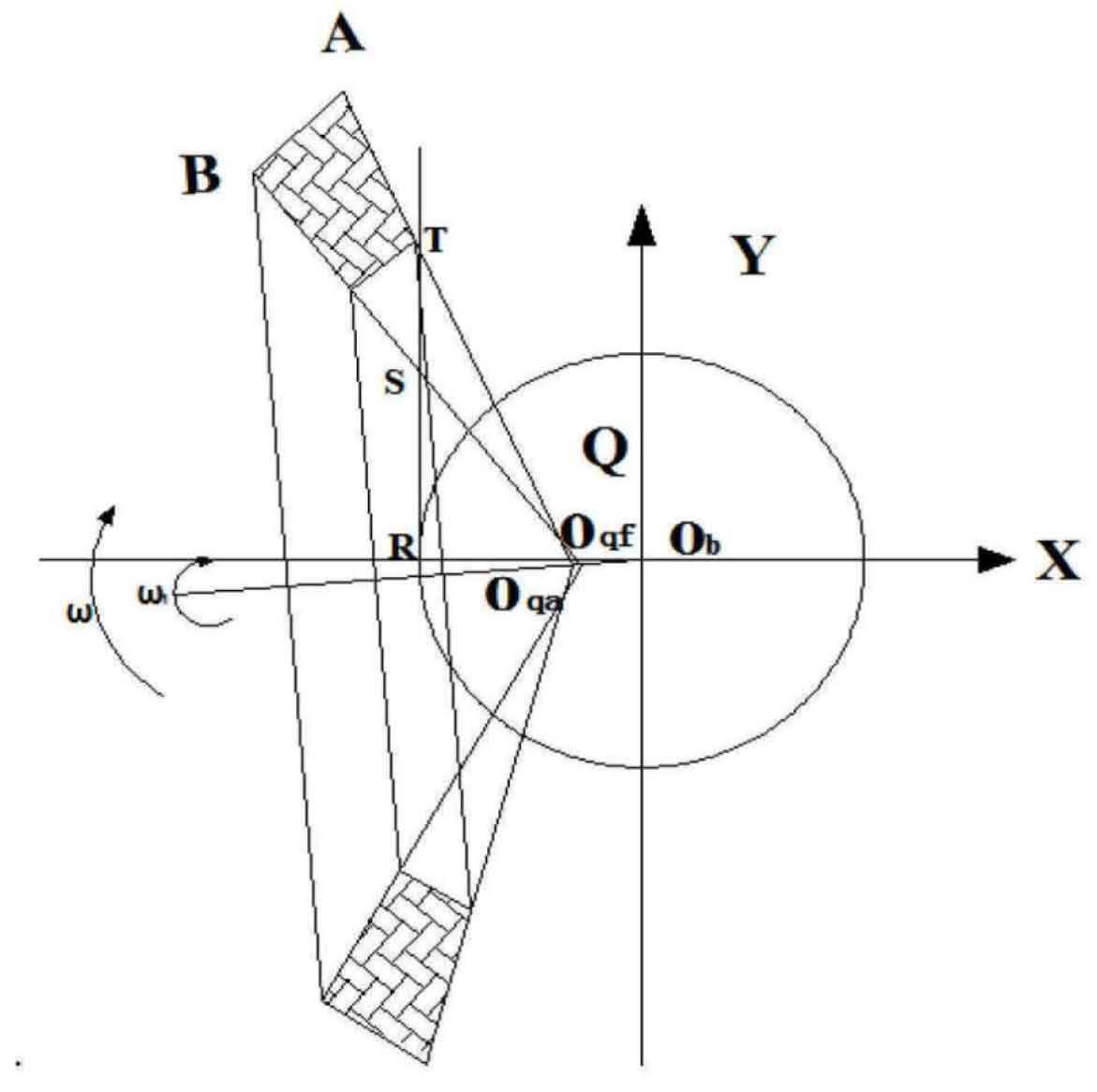

2) The tooth blank part of the left tooth surface of the hypoid gear wheel is placed in the first quadrant for machining. At this time, the outer edge of the milling cutter is used. As shown in Figure 2, the gear blank rotates counterclockwise and rotates accordingly. The profile line is tangent from the small end of the gear to the big end along the tooth root line on the base plane, and is tangent from the tooth root of the small end to the tooth top of the big end.

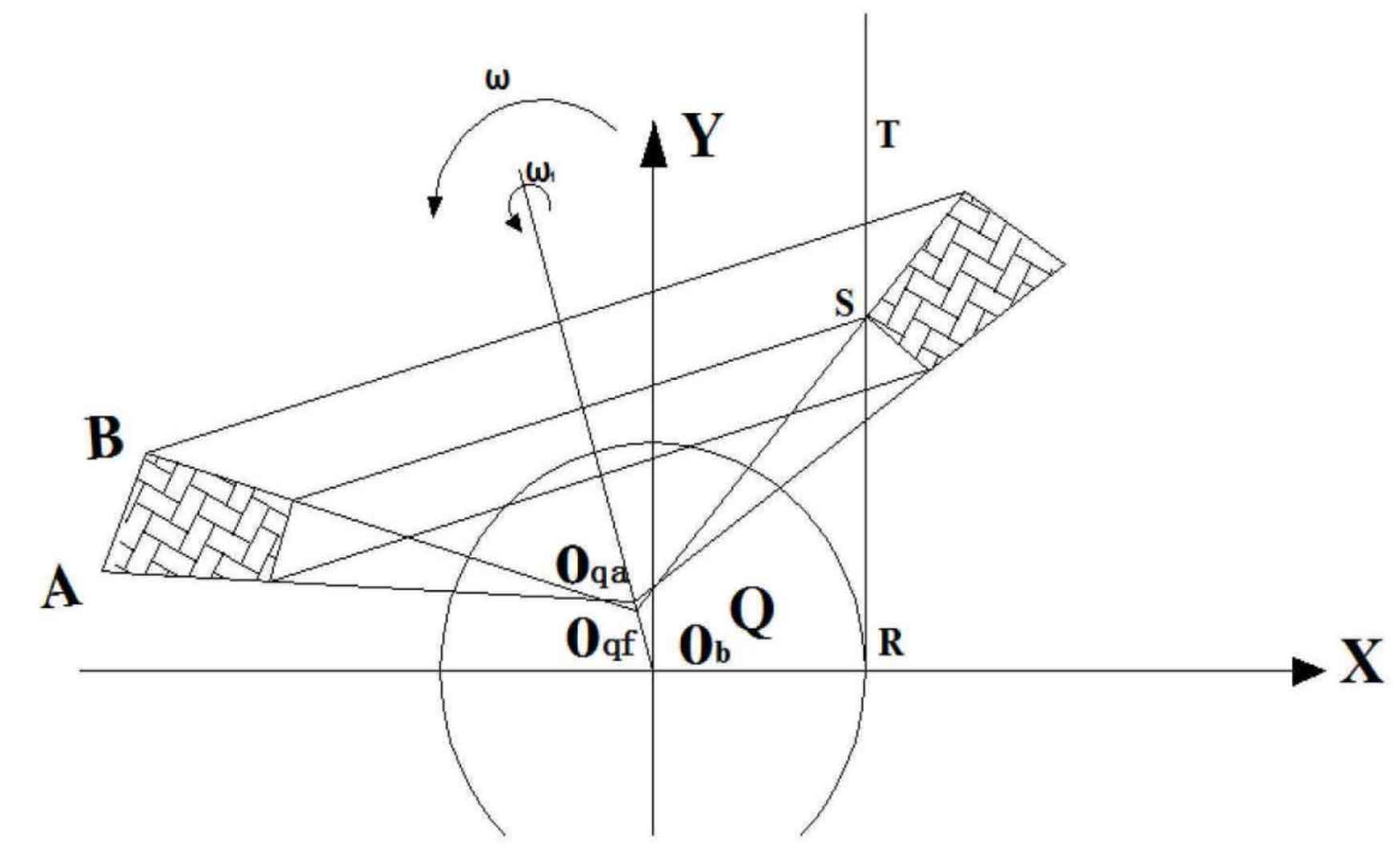

3) Place the blank part of the left tooth surface of the large hypoid gear wheel in the third quadrant for machining. At this time, the outer edge of the cutting edge is used for machining. The blank rotates counterclockwise and rotates accordingly. The situation is similar to that of method 2, so it will not be detailed here.

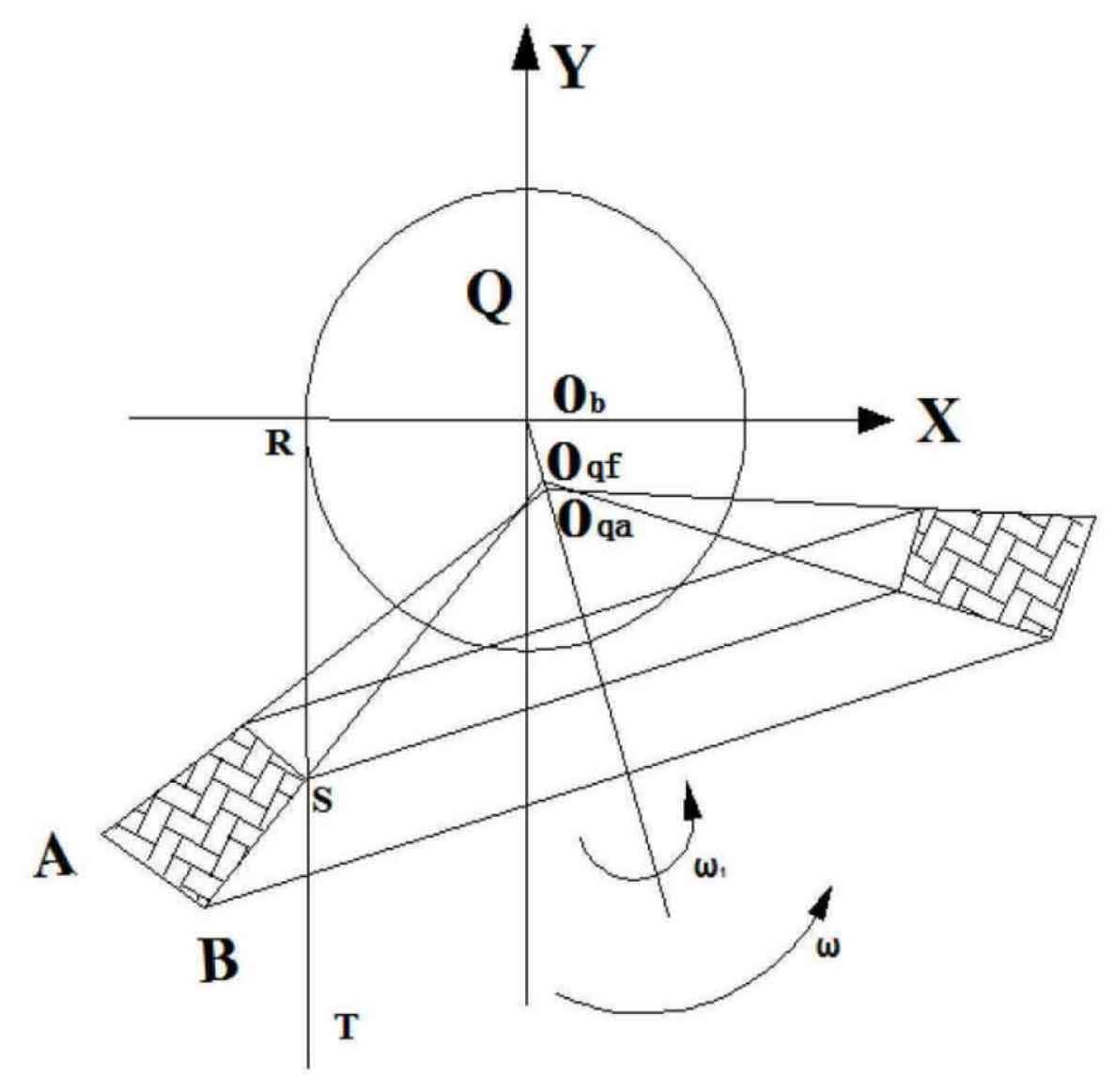

4) Place the blank part of the left tooth surface of the large hypoid gear wheel in the second quadrant for machining, as shown in Figure 4. At this time, the outer edge of the cutting edge is used for machining, and the blank rotates clockwise and rotates accordingly. The situation is similar to that, so it will not be detailed here.