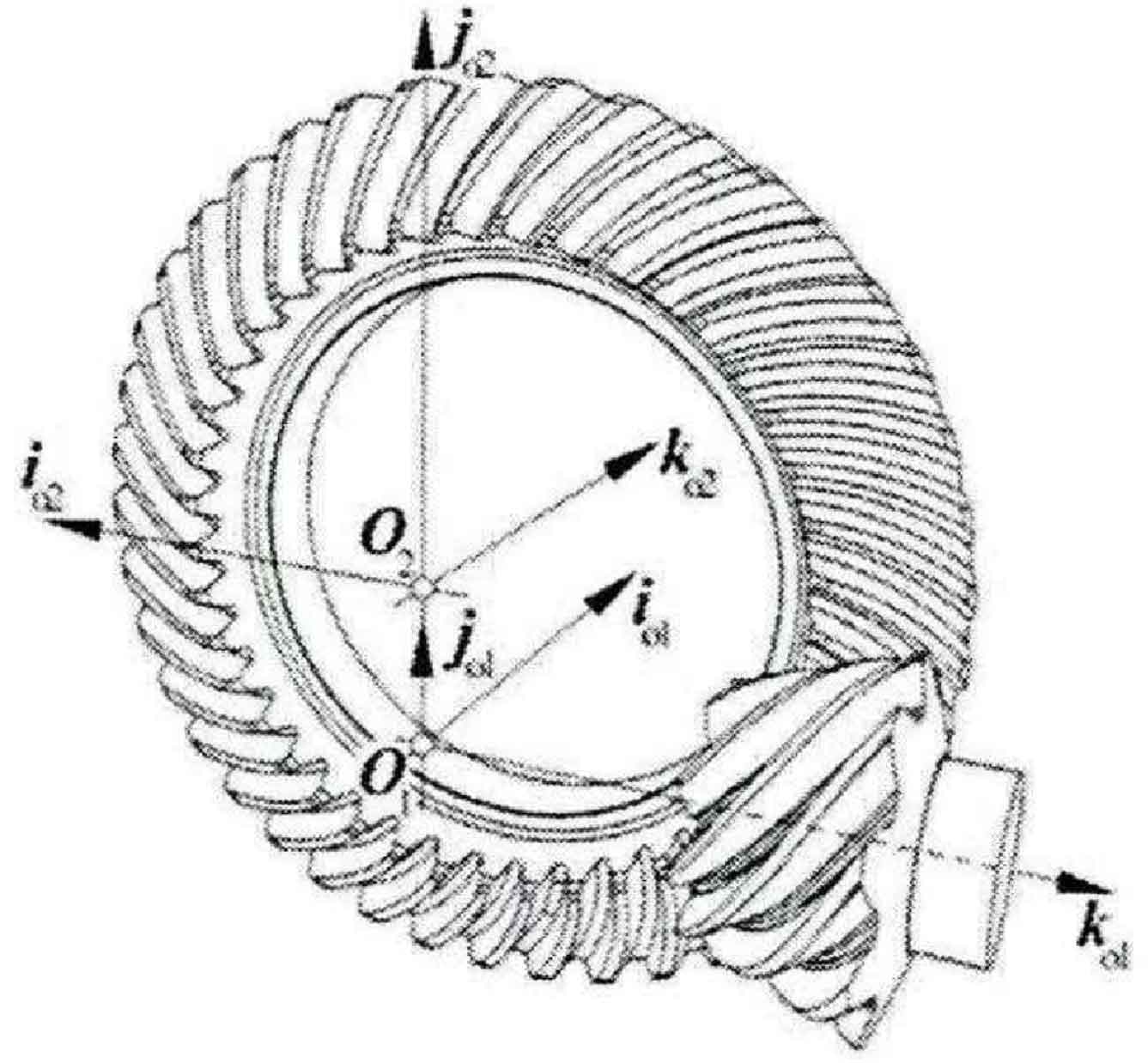

In the design and manufacture of Cycloid Bevel Gears and hypoid gears, in order to check the gear cutting adjustment calculation, evaluate the meshing quality of gear pairs, estimate the influence of assembly errors on the tooth surface contact area and motion errors, and determine the correction amount of gear cutting adjustment parameters required to improve the meshing quality, The matching two gears are installed according to the working position required by the drawing, and the meshing motion of the gear pair is simulated by computer to determine the position, size, shape and motion error of the tooth surface contact area. This process is called tooth surface contact analysis (TCA). During meshing, the position relationship of the matching hypoid gear pair is shown in Figure 1.

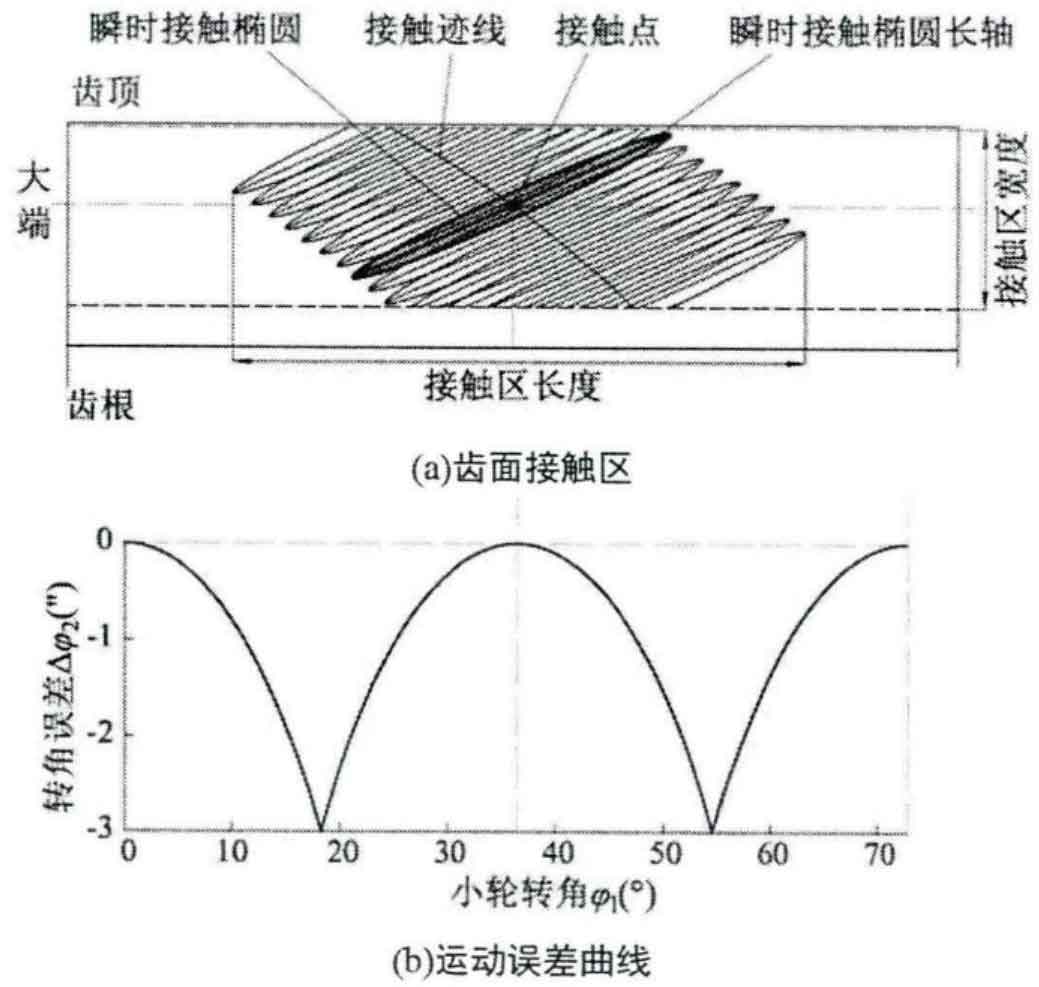

It is an effective means to check the contact quality of the tooth surface. From the TCA analysis diagram, as shown in Figure 2 – (a) is the convex contact area of the big wheel, (b) is the motion error curve, the meshing information of the gear pair can be obtained as follows:

(1) Contact trace: the trace of the instantaneous contact point on the tooth surface during the meshing process of the point contact bevel gear and hypoid gear pair is called the contact trace. The contact trace is closely related to diagonal contact, edge contact, fishtail contact, etc. at the same time, increasing the inclination angle of the contact trace can improve the coincidence of the gear pair.

(2) Instantaneous contact ellipse: after the point contact bevel gear and hypoid gear bear the load, any point on the contact trace expands into an instantaneous contact ellipse. The long axis of the instantaneous contact ellipse at the reference point of Cycloid Bevel Gear and hypoid gear roughly determines the length of the impression, It is an important evaluation index of bearing capacity.

(3) Contact area: the instantaneous contact rounding on the contact trace forms the tooth surface contact area, which usually accounts for 20% – 40% of the tooth width in the length direction.

(4) Motion error curve: the shape and amplitude of the transmission error curve have a great impact on the transmission performance of the gear pair, and are closely related to the noise generated in the transmission of the gear pair.