General NC machining is often used to process Cycloid Bevel Gears and hypoid gears, and the mold cavity used in gear mold processing. According to the method of establishing the tooth surface mathematical model of Cycloid Bevel Gear and hypoid gear pair, the sources of gear pair models are divided into:

(1) Establishing gear model by discretization of tooth surface

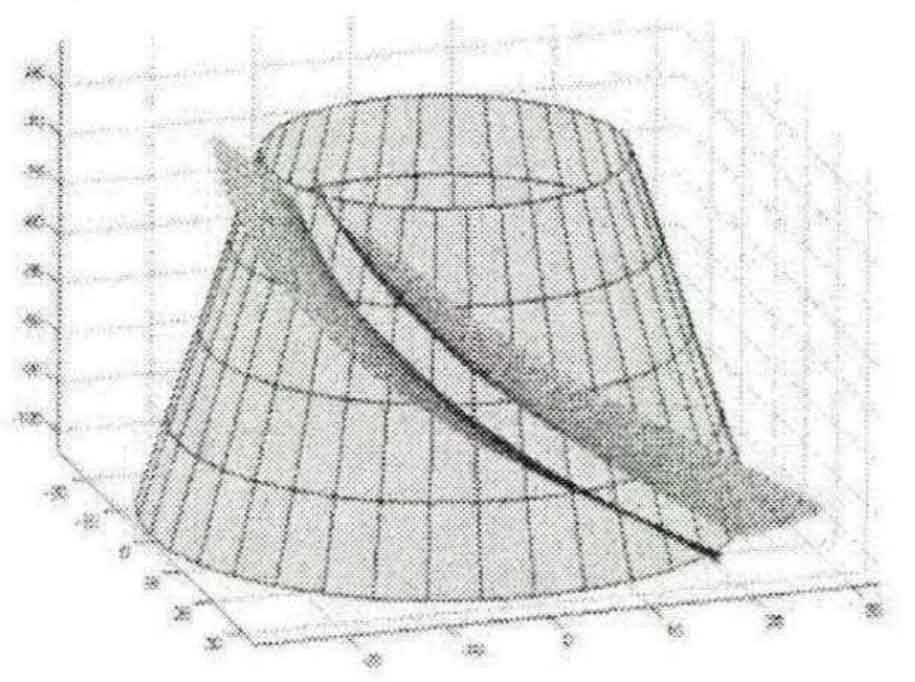

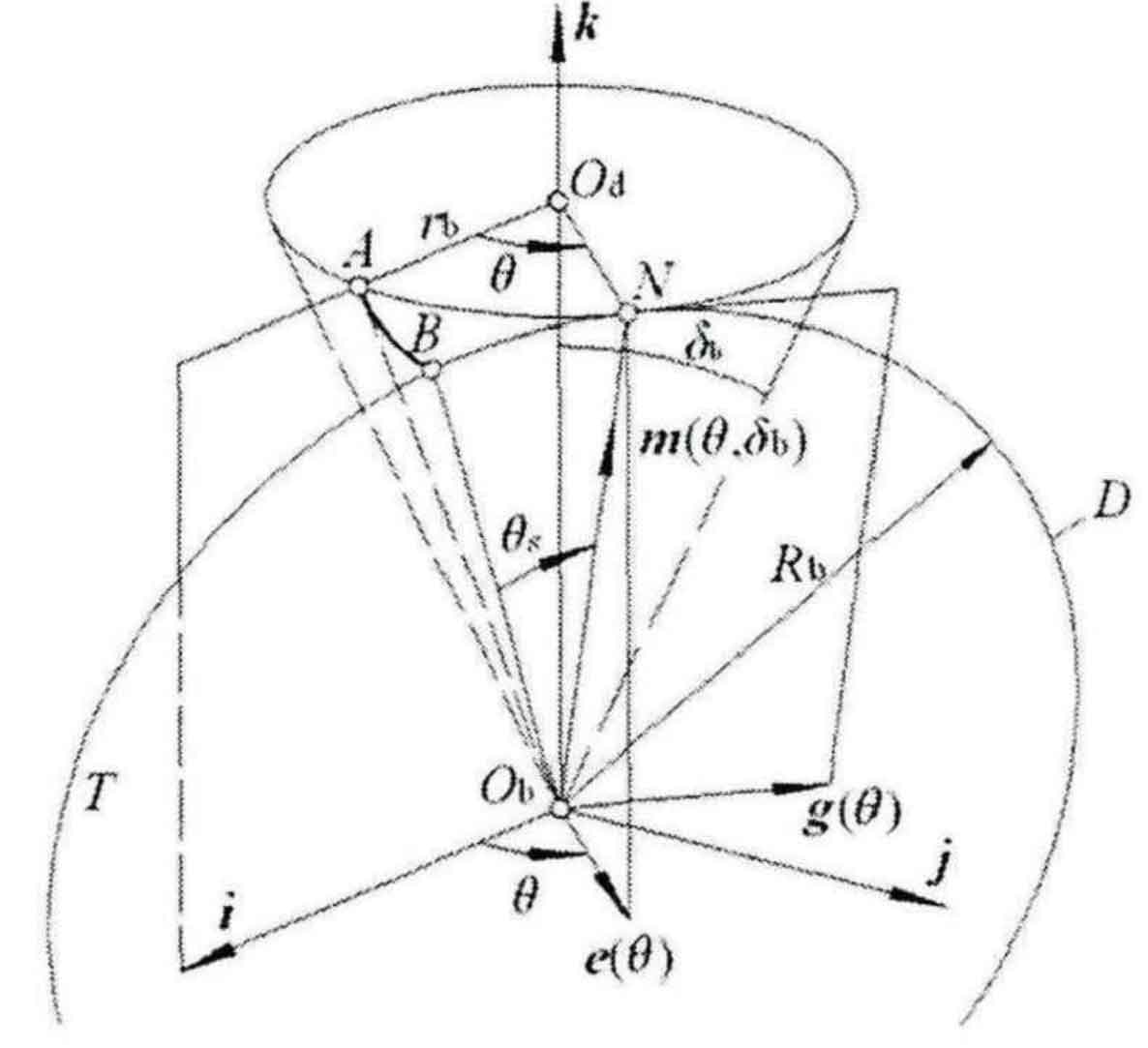

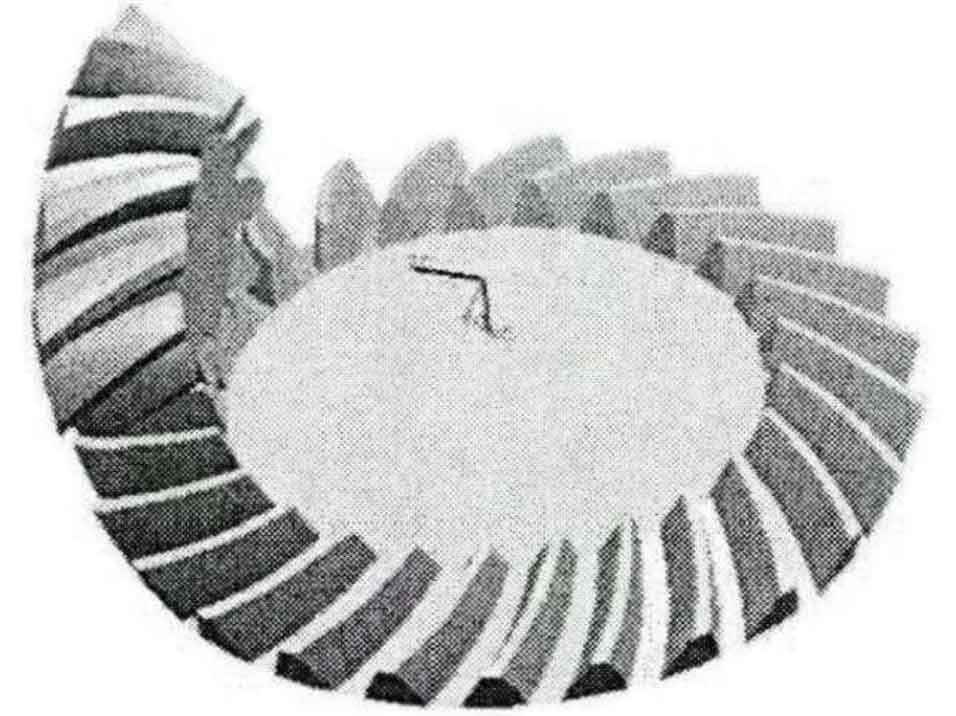

According to the meshing principle and the relevant motion relationship during machining, the tooth surface equation is obtained, the position of the point on the blade and the rotation angle of the cutter head are changed, and the discrete points of the tooth surface are calculated, as shown in Figure 1. Based on the software drawing function, the tooth surface is fitted by discrete points to establish a three-dimensional solid model of the gear, as shown in Figure 2.

(2) Brief introduction of establishing gear model by fitting tooth profile curve

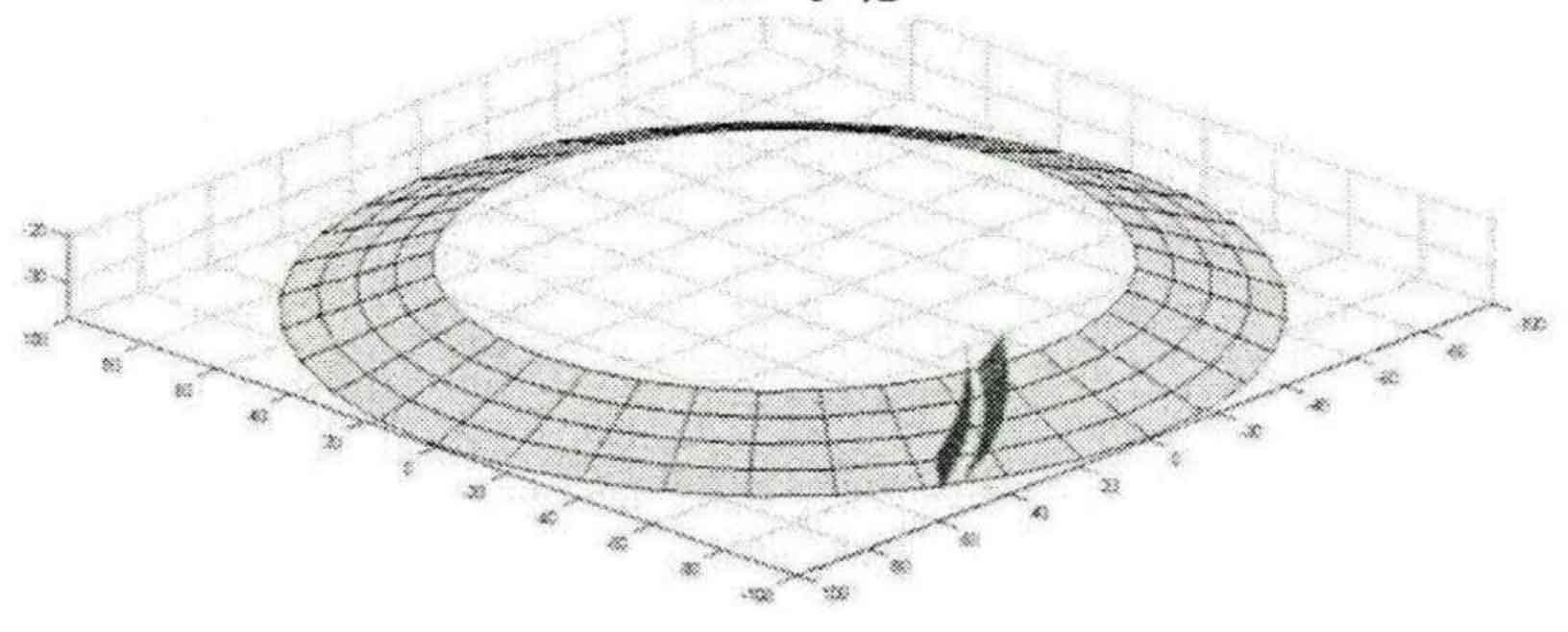

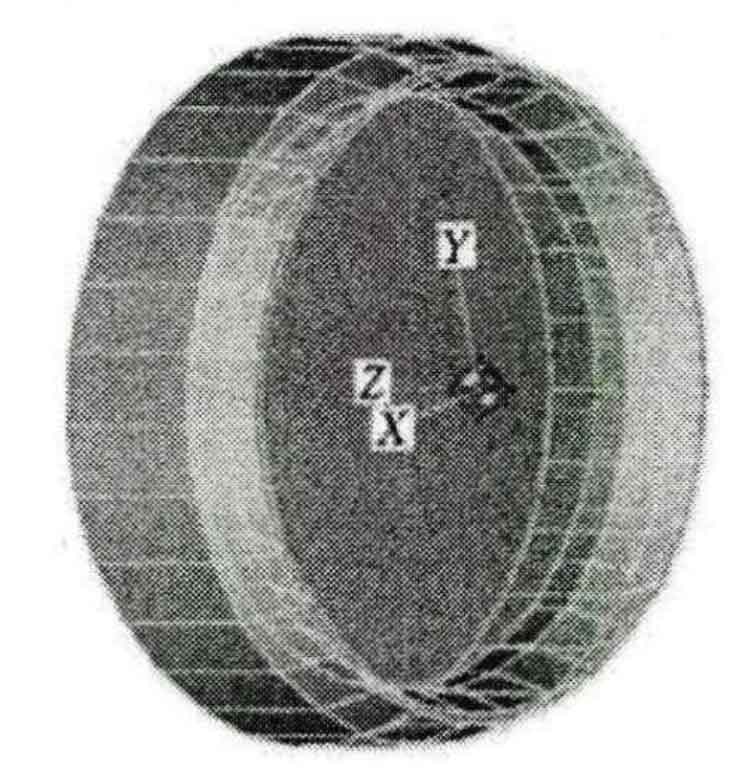

The mathematical equation expression of the tooth profile curve is derived, and the parametric modeling module of the three-dimensional modeling software is imported to build the surface and establish the gear solid model. Figure 3 is the schematic diagram of spherical involute forming of spiral bevel gear, and Figure 4 is the solid model of spiral bevel gear based on solving the tooth profile curve equation based on spherical involute theory.

(3) Brief introduction of establishing gear model by simulation forming

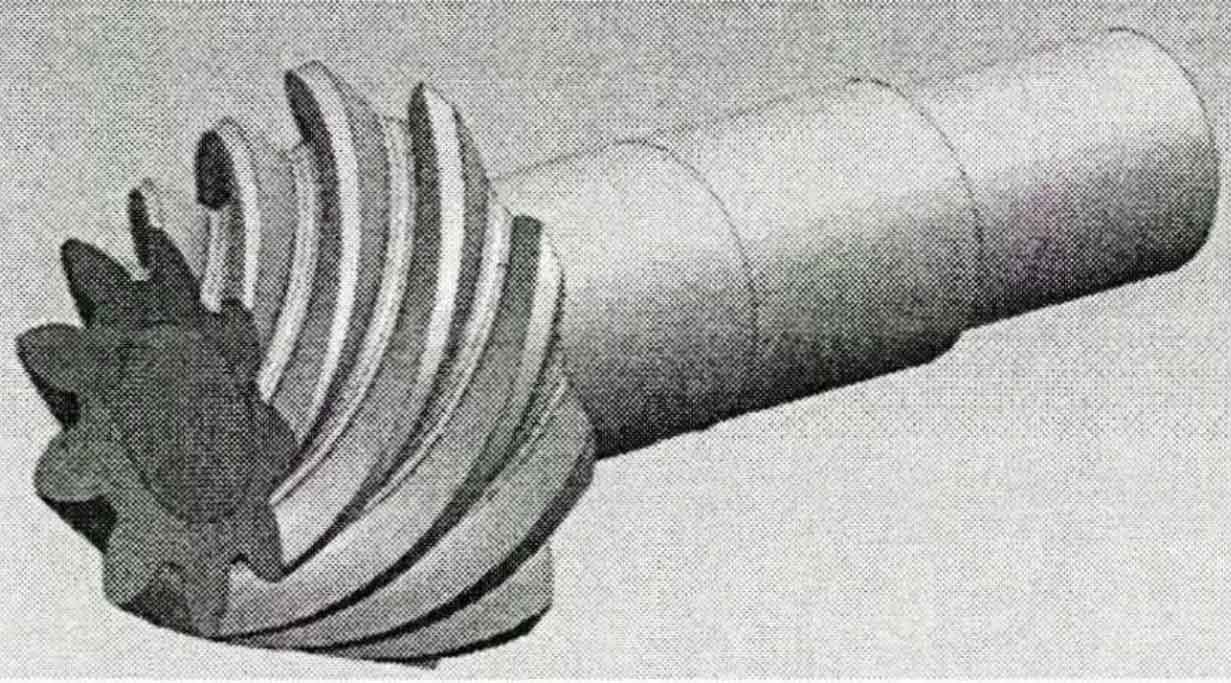

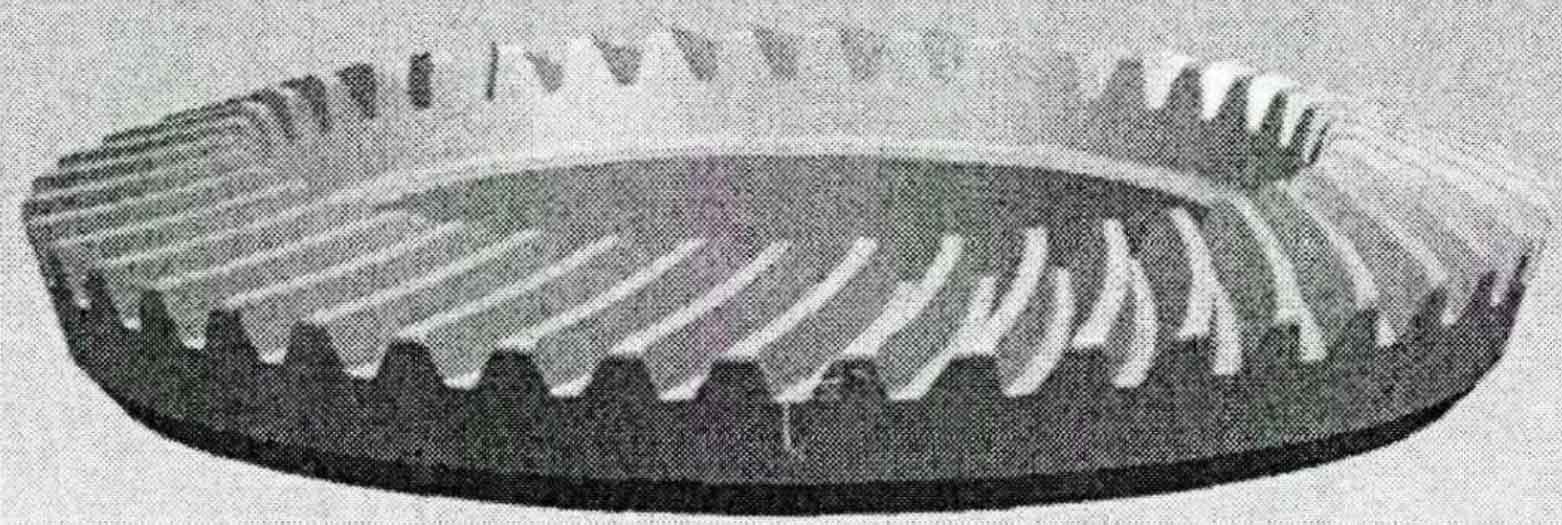

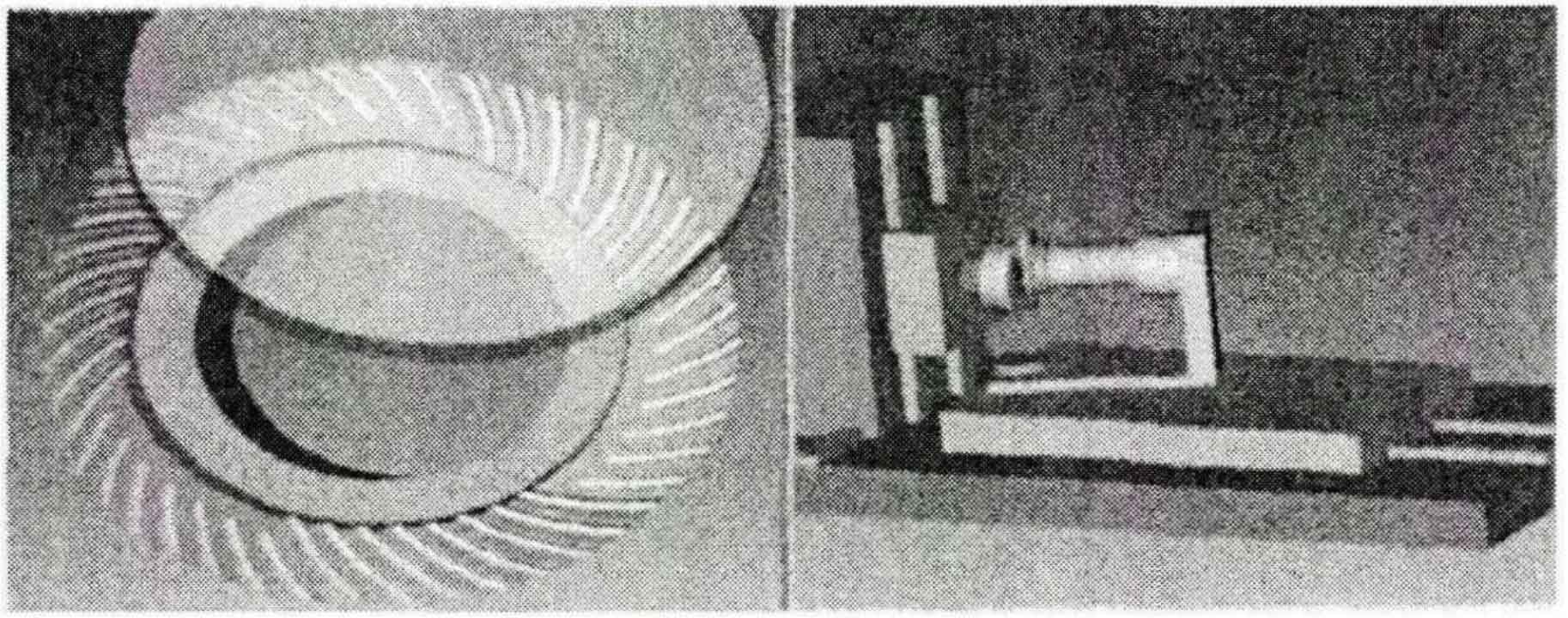

The entity of the tool or one of the gears is established, and the entity model of the corresponding gear is obtained by Boolean operation through the actual motion relationship. According to the machining principle of circular arc bevel gear and the structure and motion relationship of machining machine tool, this paper establishes the conical surface equation and meshing equation of cutting edge, calculates the motion parameters of NC machine tool, and establishes the three-dimensional model of cutting cutter head based on VERICUT software platform. The three-dimensional model of large wheel cutting cutter head is shown in Figure 5 for virtual simulation machining. The gear model is obtained by subtracting through VERICUT’s internal Boolean operation. The virtual simulation processing of large wheels is shown in Figure 6.

The gear model is established by using the tooth surface discretization method. Based on the established solid model of cycloid hypoid gear pair, the general NC machining technology of Cycloid Bevel Gear and hypoid gear is studied by using the design and manufacturing integration technology, mainly including tool path design and NC programming, And completed the actual processing test.