The machine tool for machining the tooth surface of the driving wheel (small wheel) of the hypoid gear pair has a denaturing mechanism, and takes the plane generating wheel as the generating wheel of the small wheel tooth surface, and the meshing transmission ratio (i.e. the rolling ratio of the machine tool) of the generating wheel and the small wheel can be changed during the machining process. Taking the hypoid gear transmission pair composed of right-hand generating wheel and left-hand small wheel as an example, when cutting the tooth surface of the small wheel, the first surface is defined as the cutter head cutting surface of the right-hand generating wheel, and the second surface is defined as the left-hand small wheel tooth surface, then the node of the process pitch cone of the small wheel tooth surface, that is, the calculation point m of the small wheel tooth surface, is still the node of the hypoid gear pair.

When installing the cutter and the small wheel blank, it is necessary to ensure that the pitch plane of the forming wheel (parallel to the tip plane) is parallel to the common tangent plane of the small wheel surface conical surface and the large wheel root conical surface, and that the hobbing processing is accompanied by a linear feed motion to cut to the tooth depth, so as to ensure that the tooth root surface is processed while the small wheel tooth surface is processed. In this way, the cutting pitch cone of the small wheel is equal to the process pitch cone, that is, the axis of the cutter head when machining the large wheel is parallel to that of the small wheel, which can fundamentally avoid the phenomenon of theoretical diagonal contact.

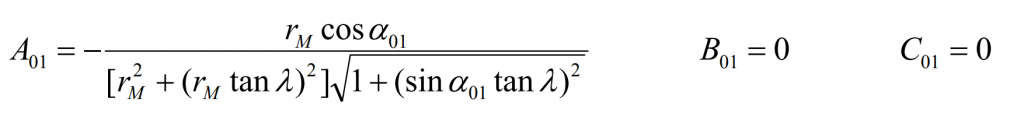

When machining a small wheel with the method of spiral denaturation, the cutting surface of the cutter head is no longer a conical surface, but an Archimedean spiral surface, which intersects with the pitch plane with a radius of RM and a rise angle of λ The helix of is the tooth shape of the generating wheel. The tangent direction of point m on the tooth line is the tooth length direction of the hypoid gear, and the generatrix direction of point m on the Archimedes helicoid is the tooth height direction of the hypoid gear. Let the three second-order contact parameters of the generating wheel be A01, B01 and C01, which represent the normal curvature along the tooth length direction, the normal curvature along the tooth height direction and the short-range torsion of the generating wheel at point m respectively, and the expression is:

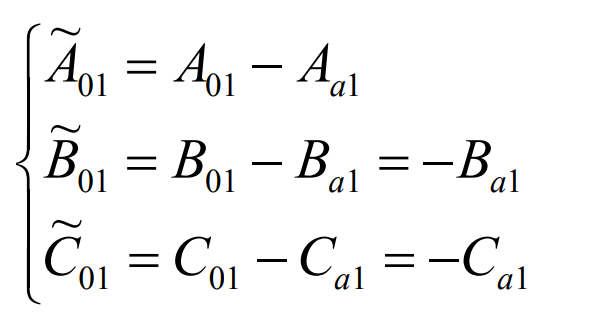

The induced curvature of the small wheel and the production wheel at point m is:

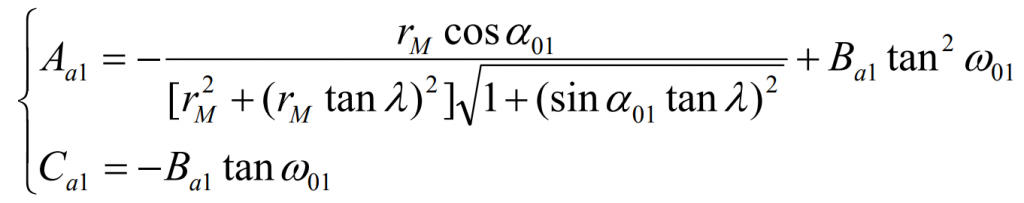

Let the direction angle of the contact line between the production wheel and the small wheel at node m be ω 01, according to:

Then the curvature expression at the m point of the pinion tooth surface is:

According to the above formula, the forming radius RM and Tan of the cutter head can be obtained ω 01。