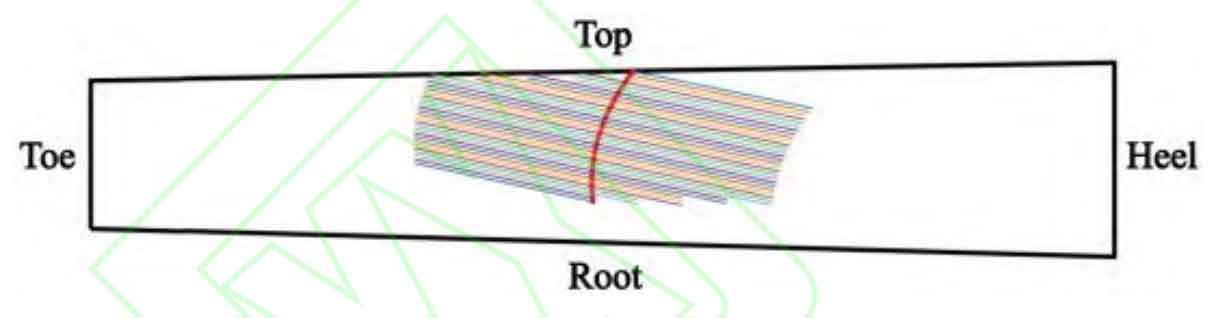

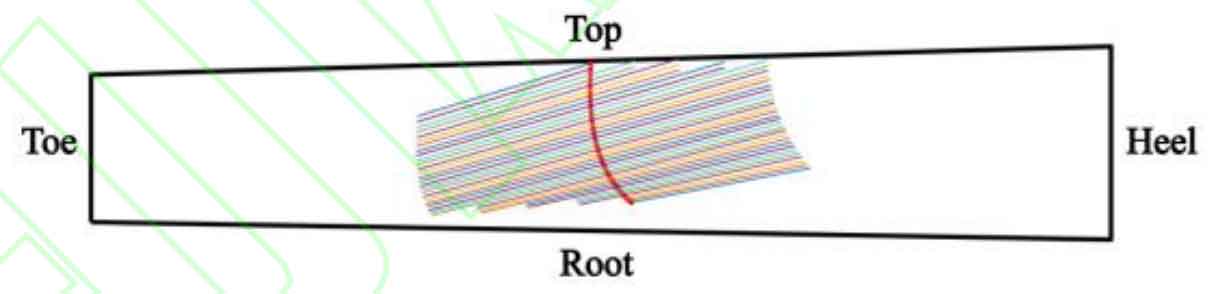

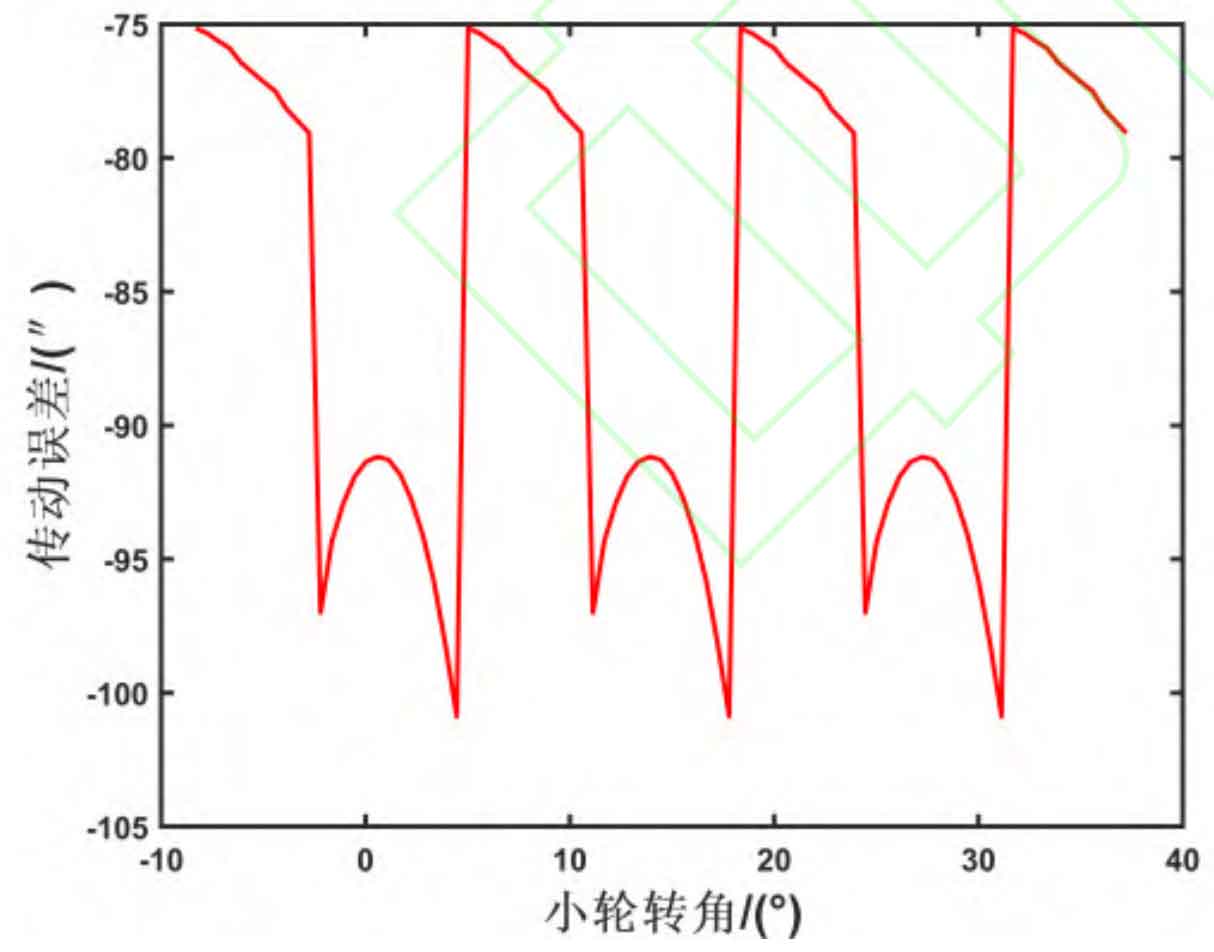

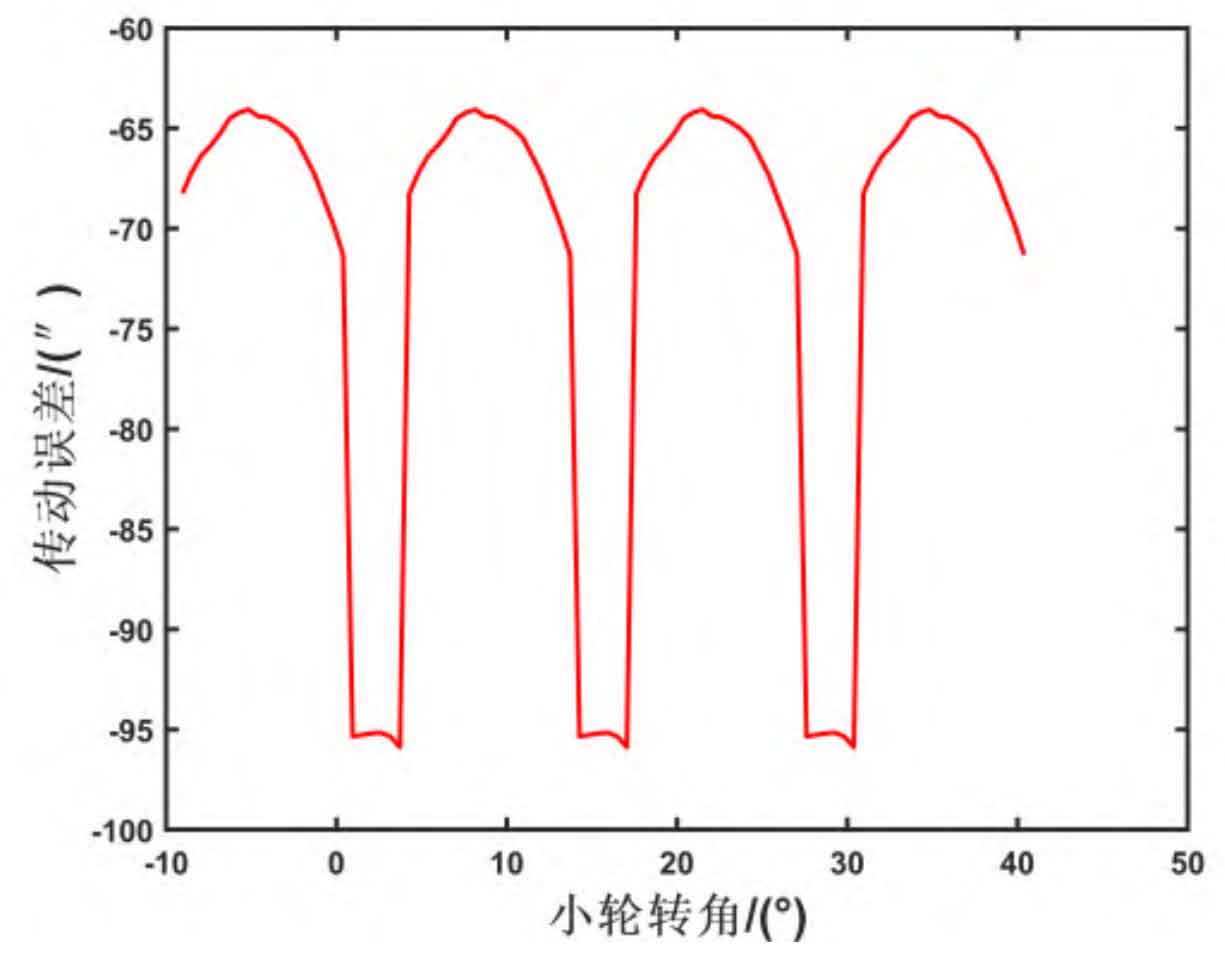

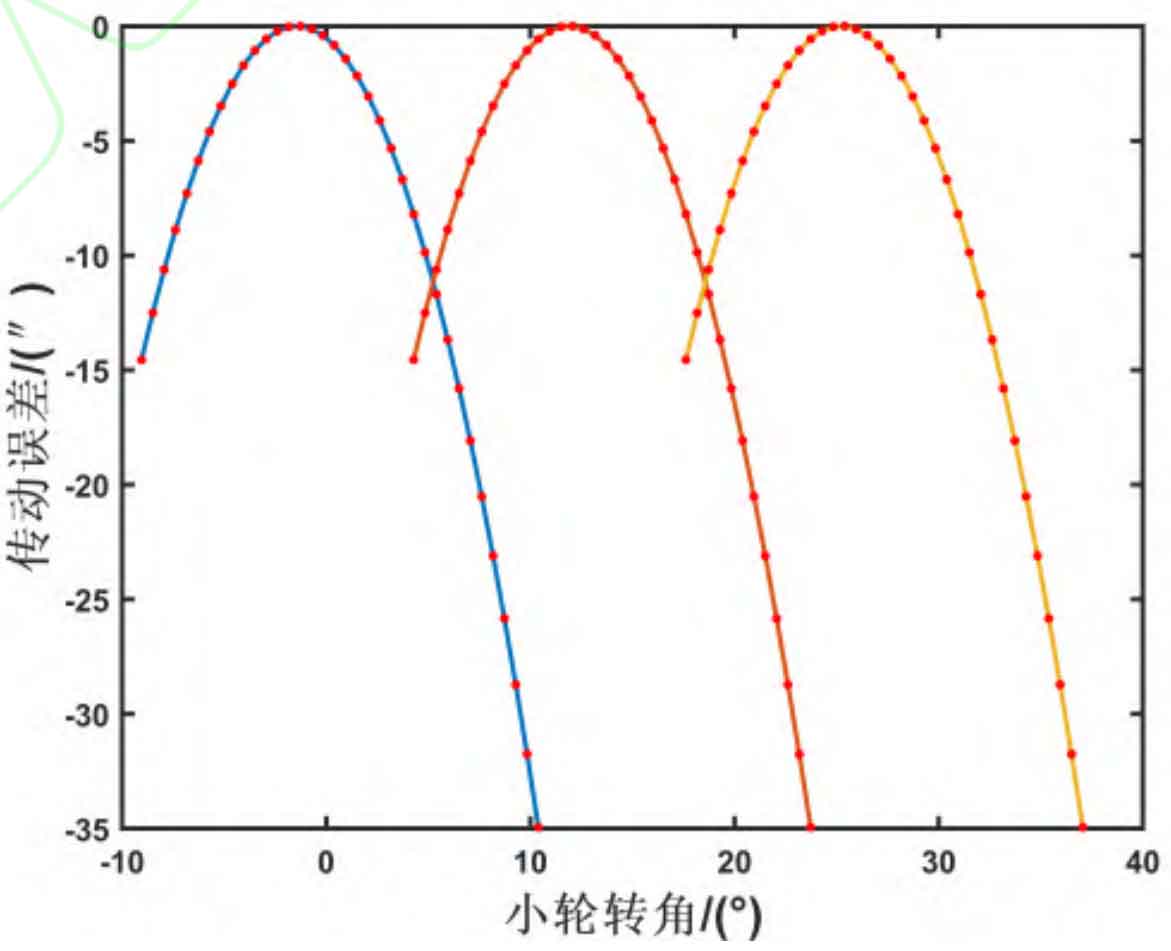

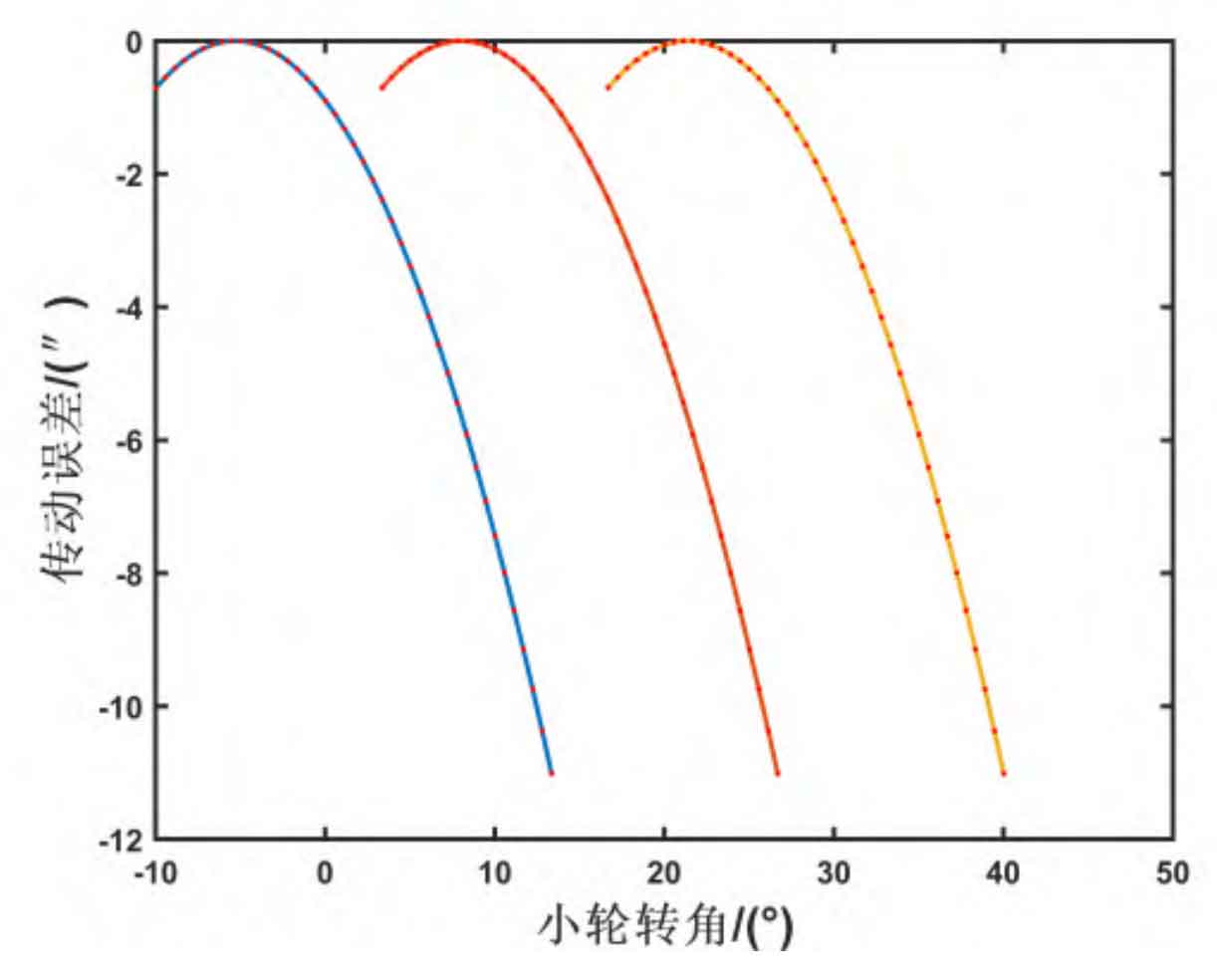

Based on TCA technology, the corresponding high-speed and heavy-duty spiral bevel gear surface impressions and transmission error curves before and after optimization are obtained, as shown in Figure 1 and Figure 2.

It can be seen from Figure 1, figure 2 and table 1: comparing the contact marks of the tooth surface before and after optimization, it is not difficult to find that the area of the meshing area and the number of meshing points of the tooth surface have increased significantly, and the inclination of the contact trace has increased, and it tends to be more straight; The coincidence degree is very sensitive to the change of the included angle between the contact trace of the convex surface of the big wheel and the cone of the big wheel root. Reducing the included angle, the coincidence degree increases significantly, and the optimized coincidence degree increases by 16.69% compared with that before optimization; The transmission error amplitude at the high-speed and heavy-duty spiral bevel meshing conversion is sensitive to the change of the first-order transmission ratio derivative. The optimized amplitude is 87.33% lower than that before optimization; The radius of the long shaft of the contact ellipse on the convex surface of the large wheel and the tooth width ratio have little influence on the coincidence degree and the transmission error amplitude at the meshing conversion.

| Parameters | Before optimization | After optimization |

| Coincidence degree | 1.458 | 1.75 |

| Transmission error amplitude at meshing conversion / (″) | 11.130 | 1.410 |

| Parameters | Before optimization | After optimization |

| Mean value of bearing transmission error / (″) | -83.2911 | -70.4445 |

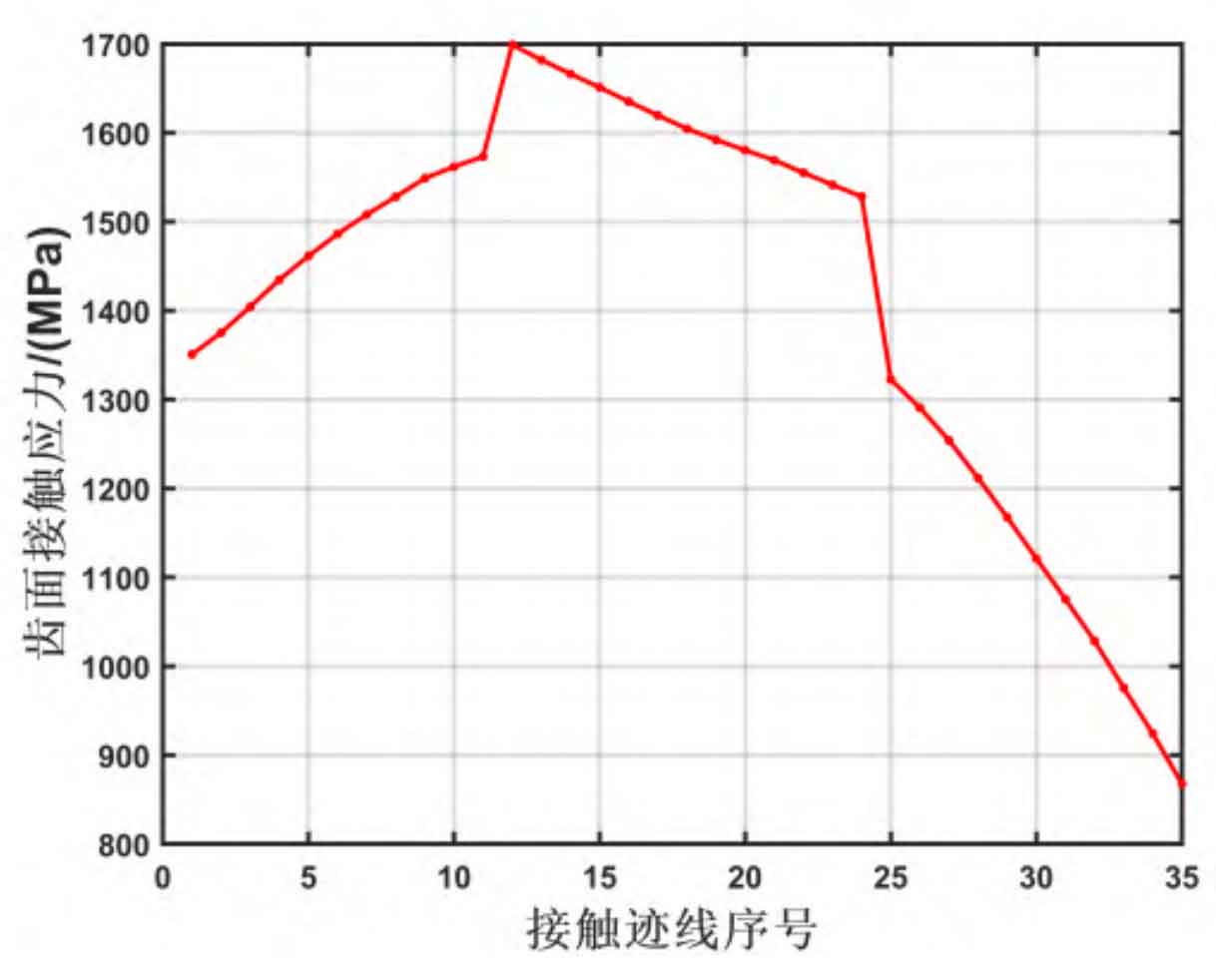

| Mean value of tooth contact stress / (MPA) | 1411.322 | 1407.748 |

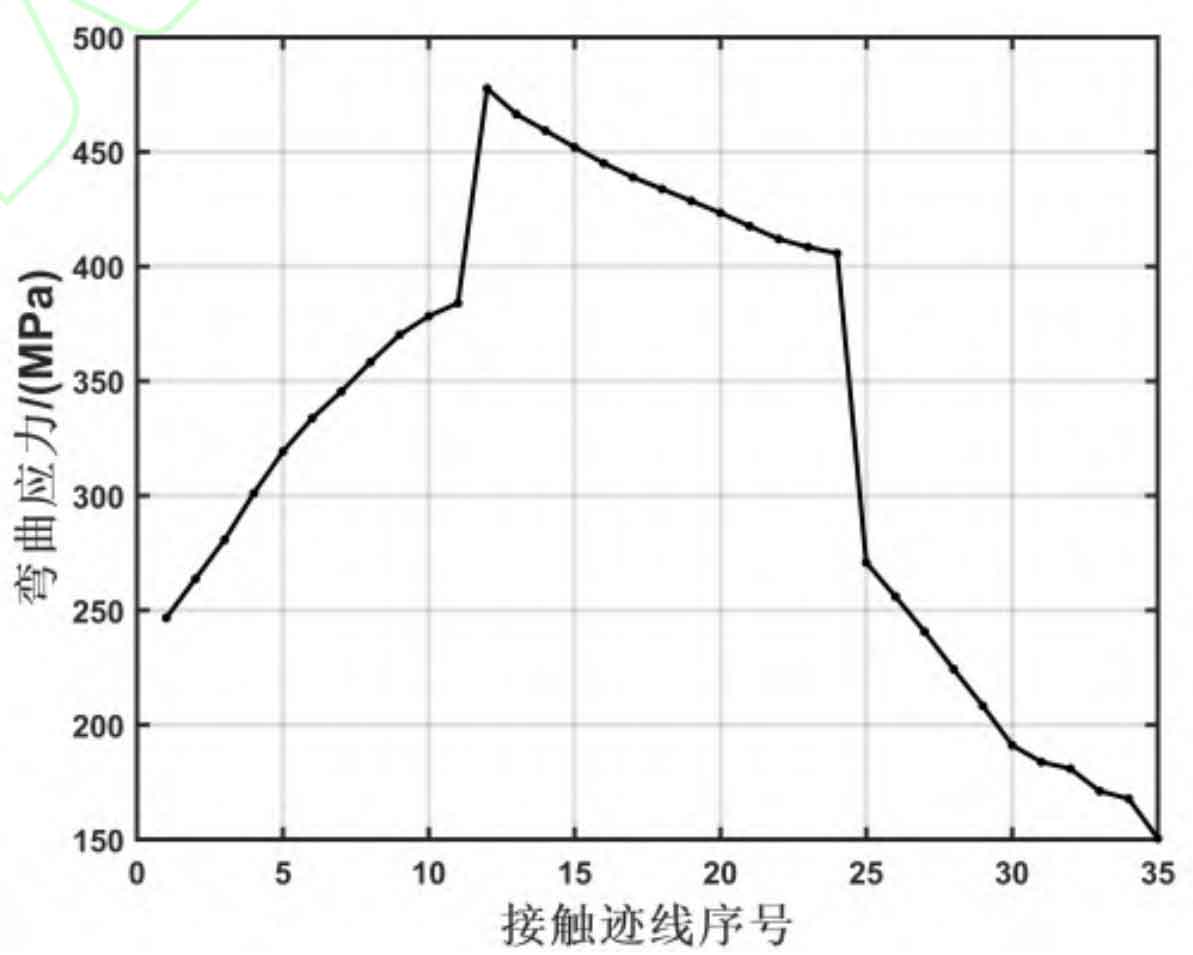

| Mean value of bending stress of tooth root of large wheel / (MPA) | 328.440 | 287.963 |

| Mean value of bending stress of pinion root / (MPA) | 321.891 | 278.068 |

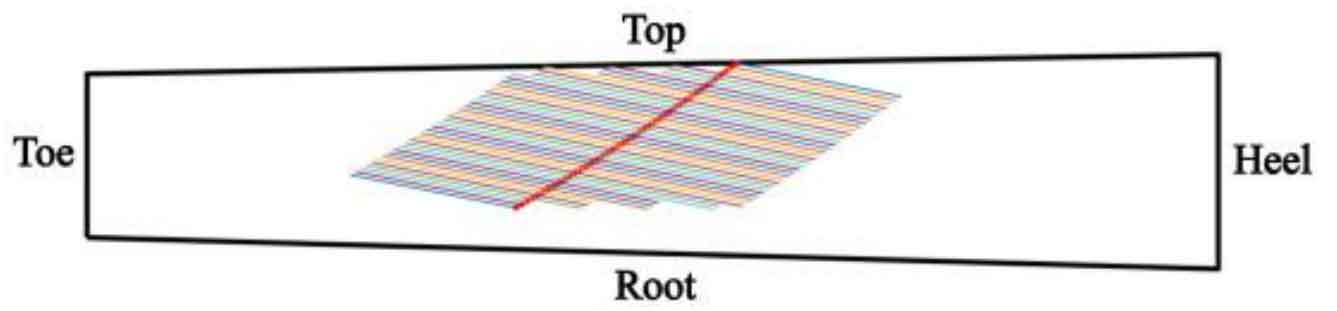

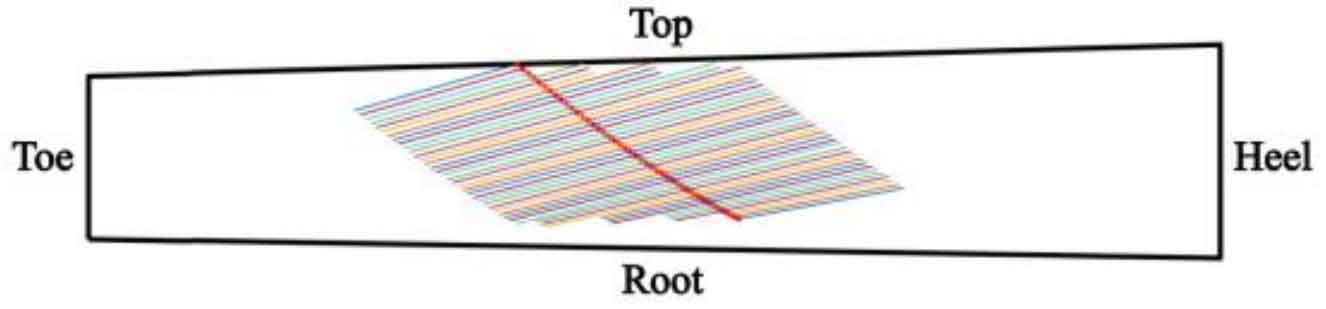

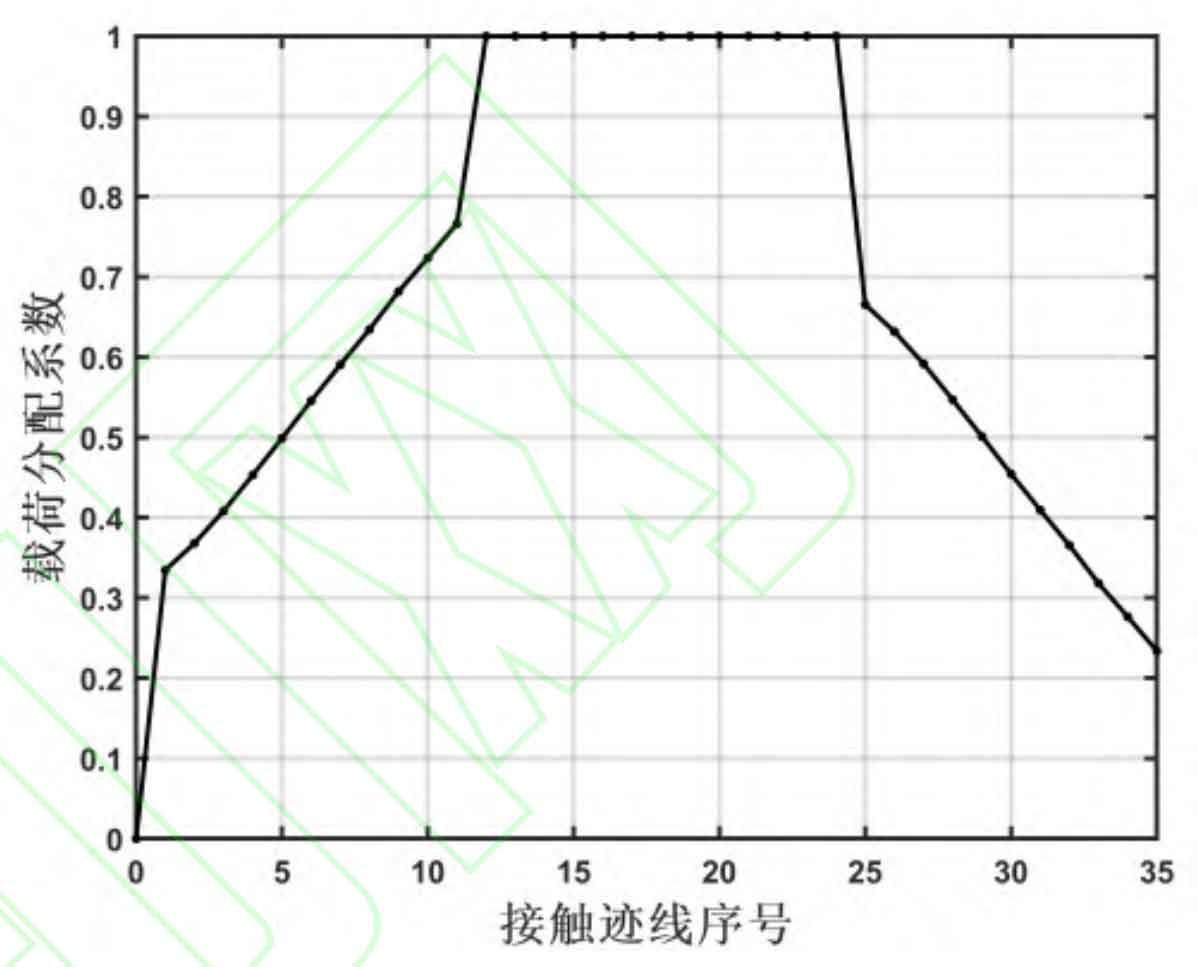

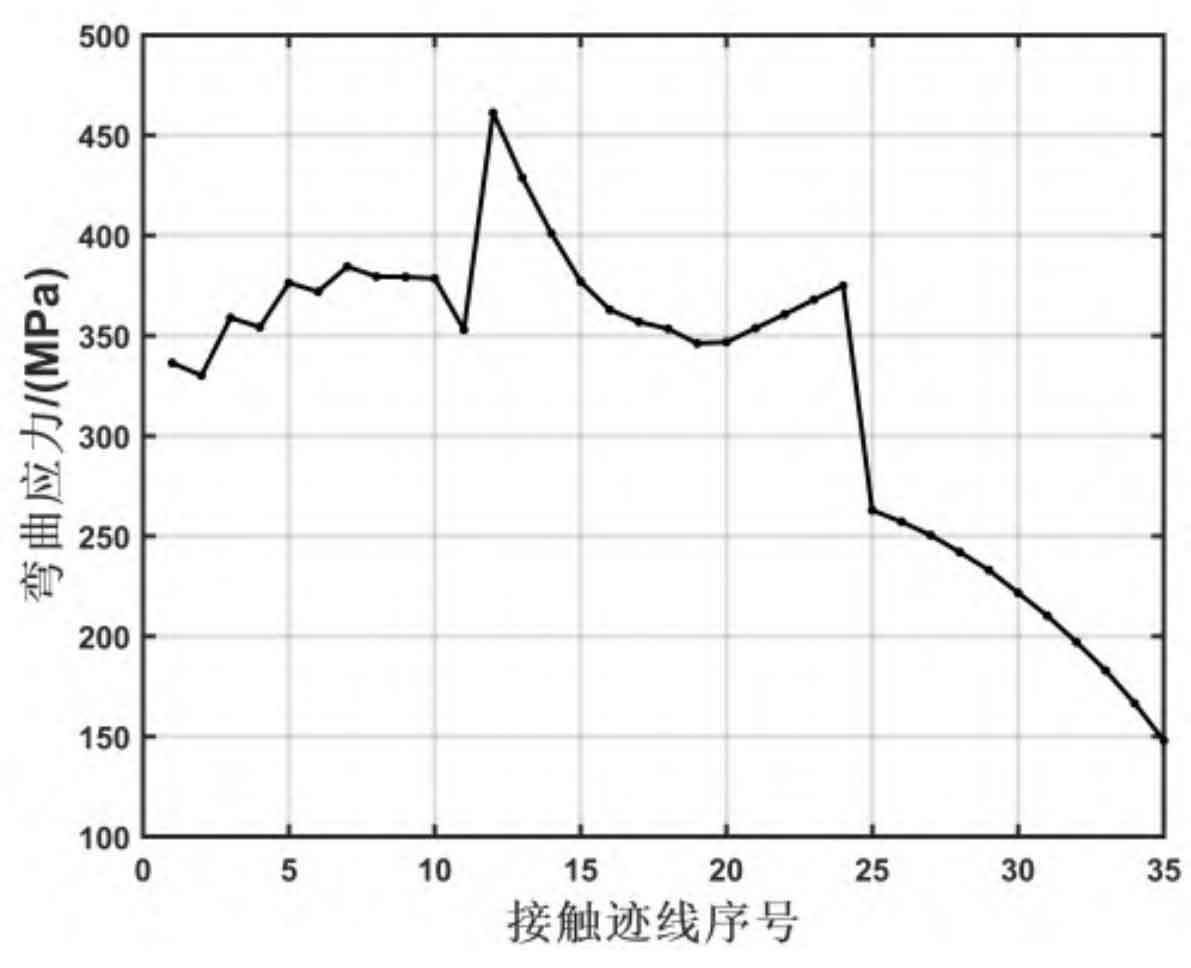

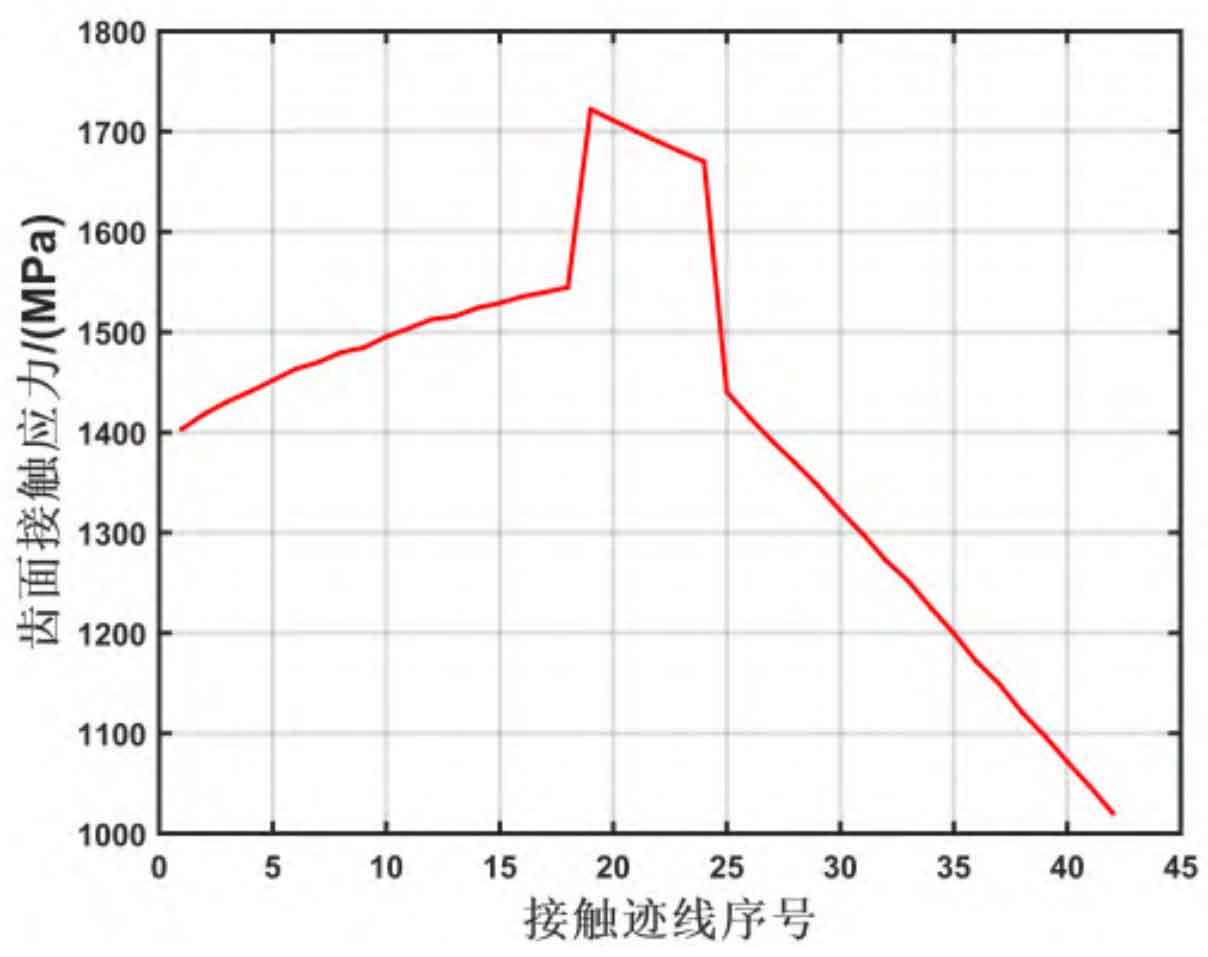

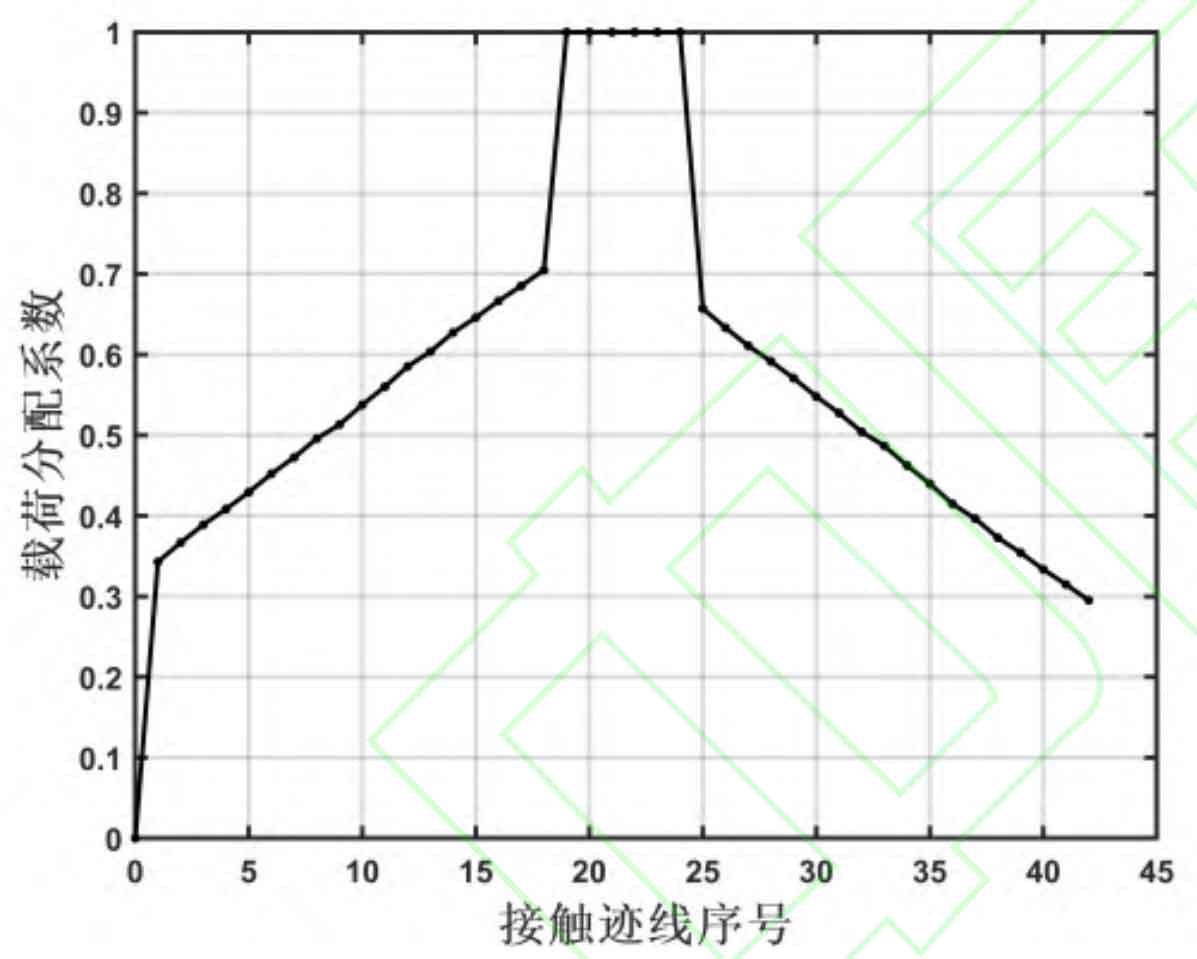

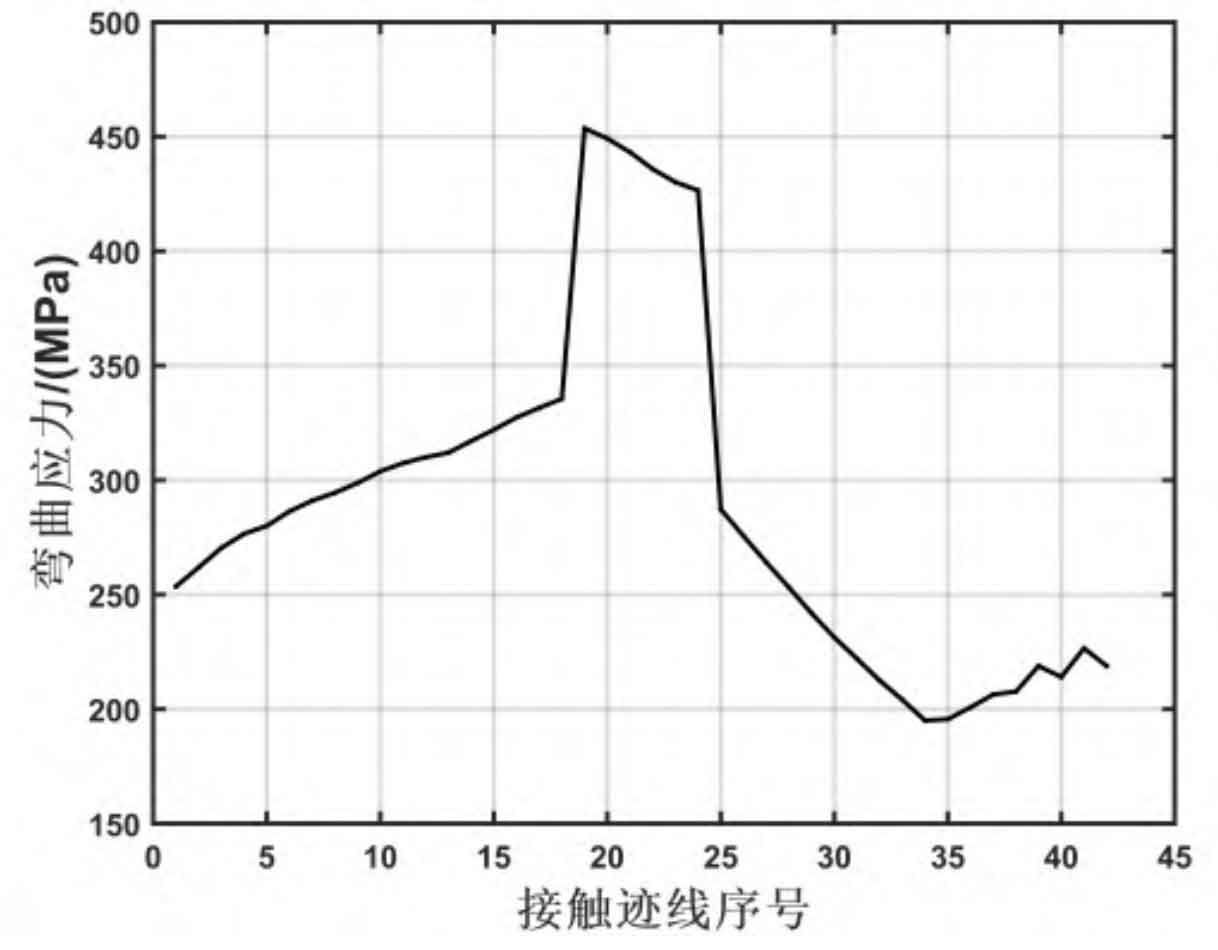

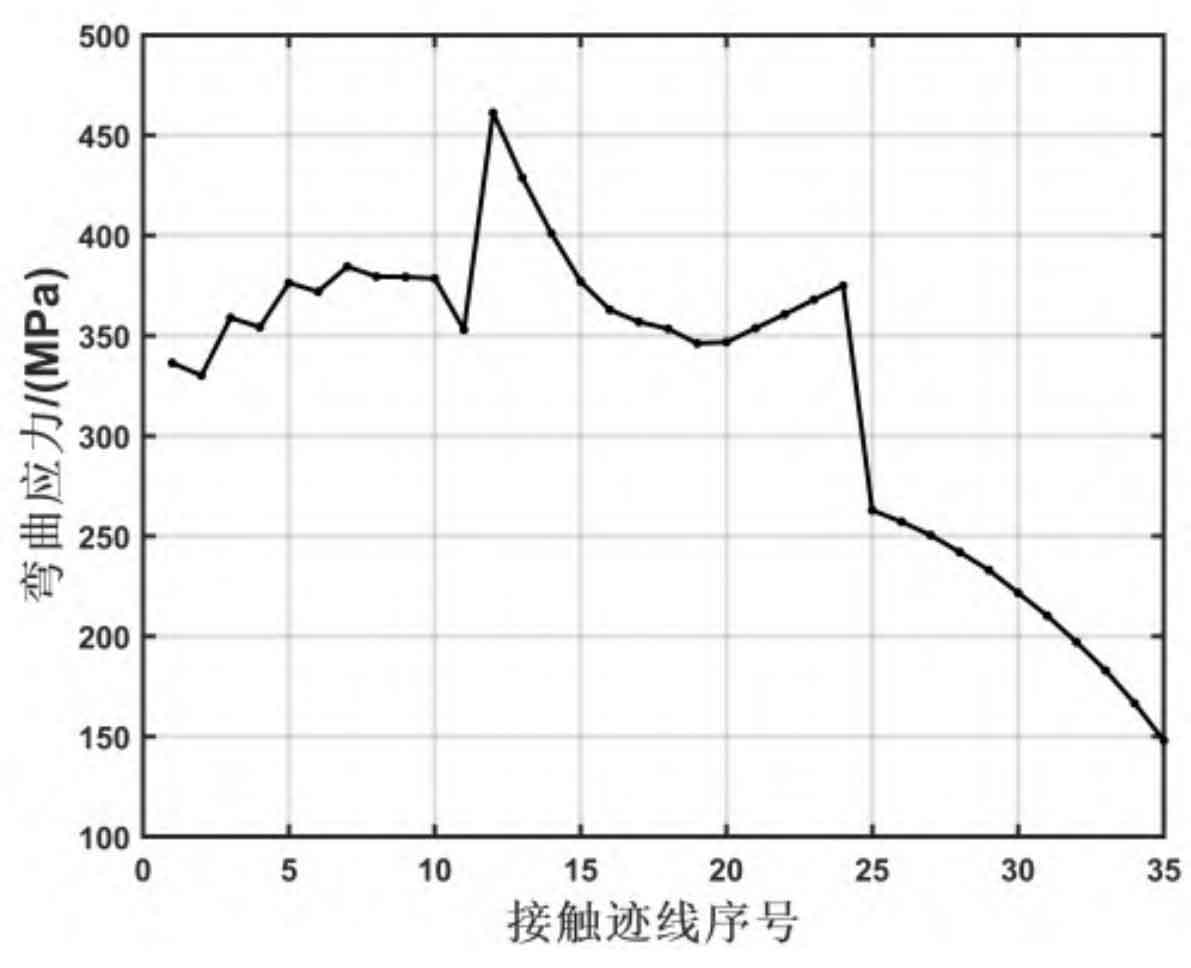

In order to further compare and verify the optimized high-speed and heavy-duty spiral bevel meshing characteristics, based on LTCA technology, the load-bearing transmission error curve, tooth surface contact stress distribution curve, inter tooth load distribution coefficient curve and the bending stress curve of large and small tooth roots before and after optimization are calculated.

Compared with FIG. 3C and Fig. 4C, due to the improvement of the design coincidence degree of the optimized tooth surface, the meshing cycle of a single tooth is significantly increased, and the proportion of a single tooth bearing a full load in a meshing cycle is significantly reduced. For the convenience of subsequent explanation, the specific numerical information involved in Figure 3 and Figure 4 is listed in Table 2. According to figure 3, figure 4 and table 2, it is concluded that after optimization, the overall load-bearing transmission error is reduced, and the mutation times in a meshing cycle are reduced, which is conducive to the smooth operation of high-speed and heavy-duty spiral bevel gear pairs and improve their dynamic characteristics; After the optimization of high-speed and heavy-duty spiral bevel gears, the mean value of contact stress on the tooth surface and the mean value of bending stress on the large and small tooth roots are reduced to varying degrees, among which the bending stress is reduced the most. The optimized tooth surface has good meshing characteristics, and the contact strength and bending strength are improved.