Taking the “Austrian” cycloid hypoid gear used in the axle as the research object, the geometric parameters and cutting parameters are calculated, and the full tooth surface model considering the blade arc and tip arc is established. The geometric contact analysis is carried out by using the improved TCA model, and on this basis, the tooth load-bearing contact analysis, edge contact analysis Stress process analysis and time-varying meshing stiffness (TMS) calculation of gear pair. By analyzing the influence of machining parameters on the tooth surface topology of cycloid hypoid gear, the combination of machining parameters that have a great influence on the tooth surface error is obtained, and the tooth surface error pre correction model is established. An active design method of cycloid hypoid gear tooth surface is proposed, which designs the tooth surface geometry according to the requirements of gear transmission performance. Based on the measurement of tooth surface error and NURBS fitting, the simulation analysis technology of actual tooth surface meshing is studied. On this basis, an active design method of cycloid hypoid gear tooth surface based on actual tooth surface is proposed. Finally, the accuracy and feasibility of the theoretical analysis method are verified by kimos5 software and the experiments of gear cutting, measurement and rolling detection. The main research work is as follows:

- The research progress and achievements of cycloid hypoid gear are summarized from the aspects of tooth surface numerical simulation, tooth TCA and LTCA, tooth surface error measurement and sensitivity analysis, tooth surface error correction, tooth surface active feed design and actual tooth surface meshing simulation.

- Tooth milling adjustment calculation and meshing simulation principle of cycloid hypoid gear. The basic principles and methods used are briefly introduced. It mainly includes the geometric parameter design of gear blank, the calculation of milling adjustment parameters, the establishment and solution of TCA basic equation, the basic principle, mathematical model and solution method of LTCA.

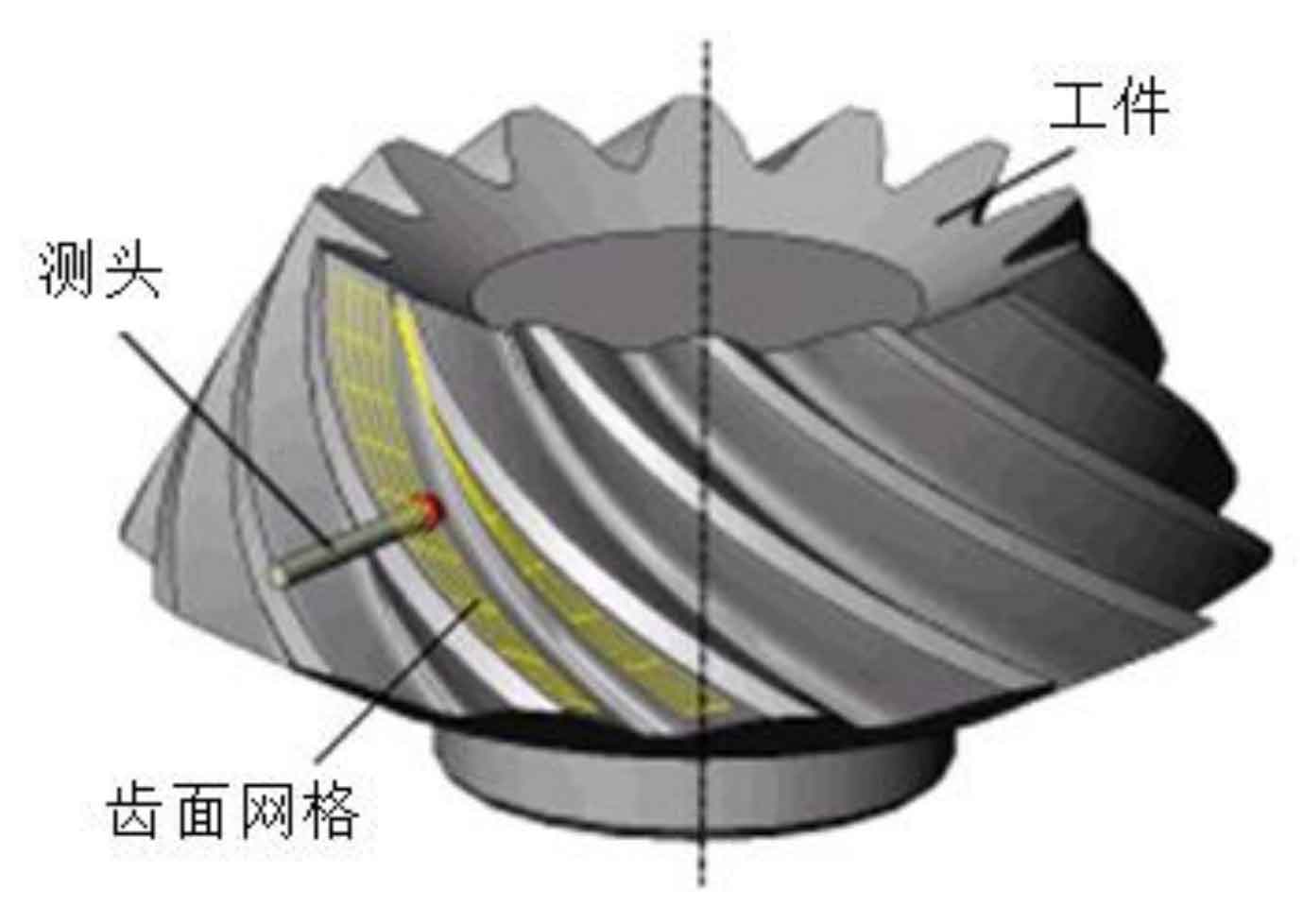

- Cycloid hypoid gear tooth surface modeling and meshing performance analysis. Considering the arc of the blade and the arc of the tip, the full tooth surface modeling method of the cycloid hypoid gear of “gram” system and “Austria” system is studied, and a new method for calculating the instantaneous contact ellipse is proposed. Taking a high-speed axle gear pair of “Austria” system spirac method as an example, the geometric contact analysis is carried out by using the improved TCA model, and LTCA is carried out on the basis of TCA, The stress process is calculated based on LTCA, and a new calculation method of time-varying meshing stiffness of gear pair is given. A geometric analysis method of cycloid hypoid gear edge contact is proposed, and the edge contact point is determined. Using this method, the edge contact analysis of a “gram” cycloid hypoid gear is carried out.

- Sensitivity analysis and pre correction of tooth surface error of cycloid hypoid gear. Using the established tooth surface model, the influence laws of various machining parameters, including tool parameters, cutter head parameters, machine tool setting parameters and hobbing ratio correction motion parameters, on the tooth surface topology are analyzed, and the machining parameter combinations that have a great impact on the tooth surface error are obtained. The pre correction optimization model of cycloid hypoid gear tooth surface error is established, and the sequence quadratic program (SQP) algorithm is used to solve the model to obtain the adjustment of each processing parameter.

- Cycloid hypoid gear tooth surface active design. Taking the theoretical tooth surface of the large wheel as the hypothetical production wheel, according to the preset angular motion relationship in the meshing coordinate system, the auxiliary tooth surface of the small wheel that contacts with the line and meets the preset transmission error curve is developed. The auxiliary tooth surface of the small wheel is modified along the direction of each meshing line according to the three parabolic modification curves determined by the preset contact marks, and the target tooth surface of the small wheel that meets the preset meshing performance is obtained. An optimization model aiming at minimizing the square sum of the normal errors between the pinion tooth surface and the target tooth surface is established. In the model, the weight coefficient is introduced to control the approximation degree of the tooth surfaces on both sides machined by the double-sided method, so that the meshing performance of one side of the tooth surface can be selectively guaranteed. Finally, SQP algorithm is used to solve the model, and the adjustment amount of small wheel machining parameters is obtained. This method provides a new way to actively control the meshing performance of both sides of cycloid hypoid gears machined by double-sided method in the design stage, and is also applicable to other gears machined by double-sided method.

- Meshing performance analysis and active design of actual tooth surface based on measurement. Based on the discrete coordinate points of the tooth surface measured by the high-precision gear measuring center, the principle and method of actual tooth surface fitting are studied. By extracting the profile value points of the fitted tooth surface, and solving the control vertices and weight factors, the high-precision fitted tooth surface and its explicit expression of the actual tooth surface, namely the digital tooth surface, are obtained. The mathematical model of meshing simulation analysis of the actual tooth surface is established and solved, and the contact mark and transmission error curve of the actual tooth surface are obtained. Compared with the traditional rolling inspection, the actual tooth surface meshing simulation analysis can obtain the transmission error curve while obtaining the contact mark of the tooth surface, which comprehensively reflects the meshing information of the actual tooth surface and avoids the inconsistency between the design and the inspection and evaluation criteria. Finally, an active design method of cycloid hypoid gear tooth surface based on the actual tooth surface, which is applied in the trial production stage, is proposed. This method comprehensively considers the deviation of the large and small gear tooth surfaces caused by machining errors and heat treatment deformation. Only one correction of the small gear tooth surface is required to obtain the expected meshing performance and shorten the trial production cycle.

- Test and comparative analysis verification. Taking a high-speed axle gear pair made by “Austrian” spirac method as an example, the tooth cutting, tooth surface measurement, roll inspection test, theoretical tooth surface modeling, geometric contact analysis and tooth surface active design are compared and verified. The results obtained by the simulation method in this paper are compared with the test results and the simulation results of klinberg’s latest version of spiral bevel gear design and analysis software kimos5, The validity and feasibility of the theoretical analysis method are verified.