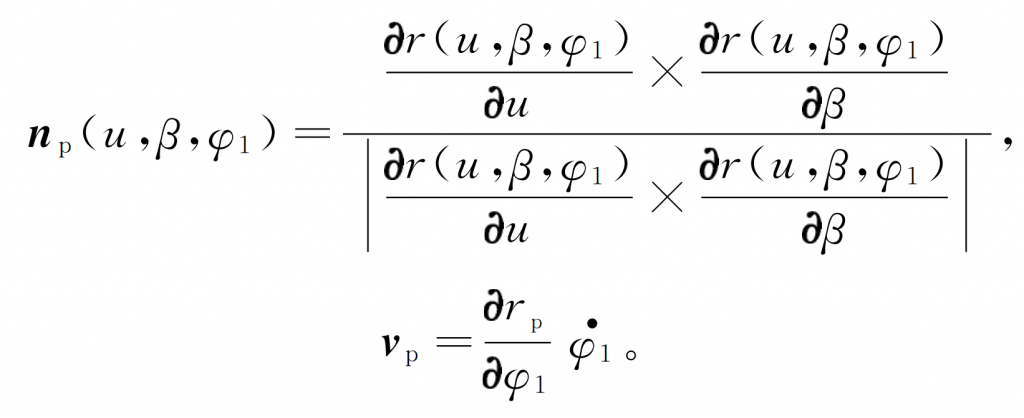

In generating machining, the tooth surface equation is still statically indeterminate through the formula, and the incremental angle of the shaking table or the rotation angle of the blank under the rotation angle of each cutter head needs to be solved through the meshing equation. Under the blank coordinate system sp (XP, YP, ZP), the normal vector and relative speed expression of the tool are:

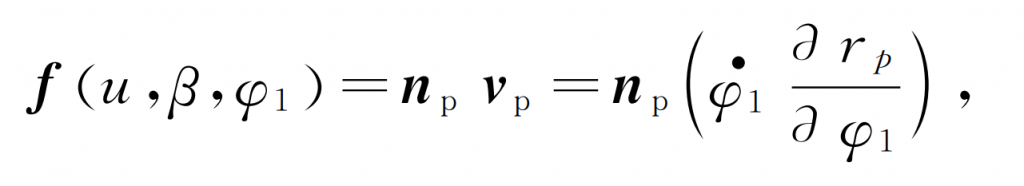

Based on the meshing theory of hypoid gears, the meshing equation of hypoid gears is:

Where: VP is the speed of the cutting edge of the tool in the blank coordinate system sp (XP, YP, ZP); RP is the vector diameter of the tool in the blank coordinate system sp (XP, YP, ZP);

φ 1 is the rotation angle of the blank; φ 1 is the unit blank angular velocity, which is generally taken as 1. By substituting the solution value of the formula into the formula, the tool cutting path surface of the generation method in the blank coordinate system can be obtained.

For the tooth surface of right-hand hypoid gear, the right-hand cutter head is used, the machining cutter head rotates counterclockwise, and the tool installation direction is along the cutting direction; In the machine tool coordinate system, the cutter head is installed in the first quadrant, the blank is installed in the fourth quadrant, and the initial installation angle and vertical gear position of the shaking table are opposite to those of the left-hand hypoid gear; The direction of blank rotation is opposite to that of left-hand hypoid gear, which is clockwise rotation. In the same way, the cutting trajectory surface equation of right-hand hypoid gear in blank coordinate system can be obtained.